Discrimination method for laser damage on the surface of a film or an optical element and determination device thereof

A technology of optical components and laser damage, which is applied in the direction of material excitation analysis, etc., can solve the problems of judgment failure, and achieve the effects of fast discrimination, wide range of types, and stable and accurate results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

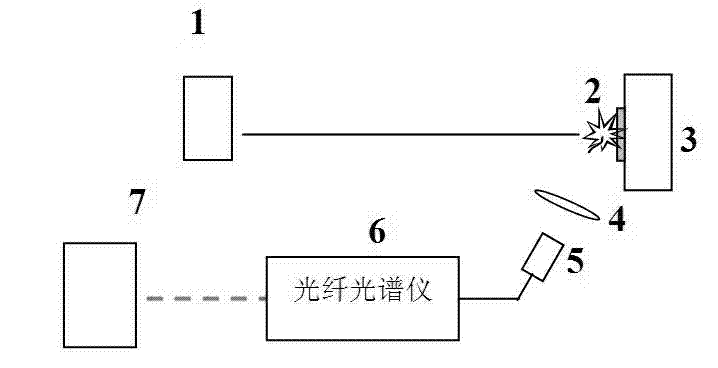

[0019] The present invention will be further described below in conjunction with accompanying drawing.

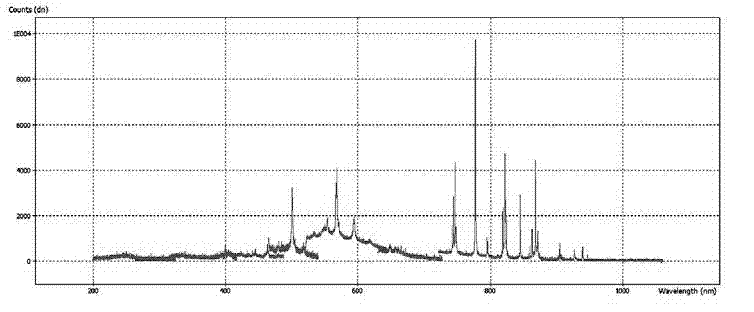

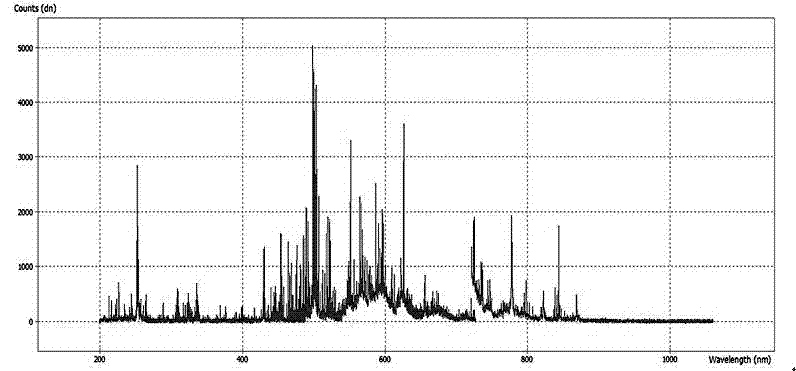

[0020] The invention provides a method for discriminating laser damage on the surface of a thin film or an optical element. The laser is used to irradiate the sample with a single pulse of laser light. If the sample surface is not damaged, no plasma flash occurs on the surface; if the sample surface is damaged , A strong plasma flash will occur at the moment of damage, analyze the flash spectrum, and if there are luminescence peaks of elements other than N, O, H, and C, it is determined that damage has occurred.

[0021] The core of this method is that instead of taking light intensity change as the criterion of damage, it adopts the method of plasma spectrum peak position analysis, and uses the difference of absorption peak position of thin film and atmospheric flash spectrum as the criterion of damage or not. Because the atmosphere mainly contains N, O, C, H and other ele...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com