Helical gas pipe forming machines

A technology for forming machines and gas pipes, applied in metal sawing equipment, sawing machine devices, manufacturing tools, etc., can solve problems such as the inability to adjust the upper and lower roll groups, no power for the upper and lower occlusal wheels, difficult machining accuracy of molds, etc., to achieve the pressing force Strong, reasonable layout, wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

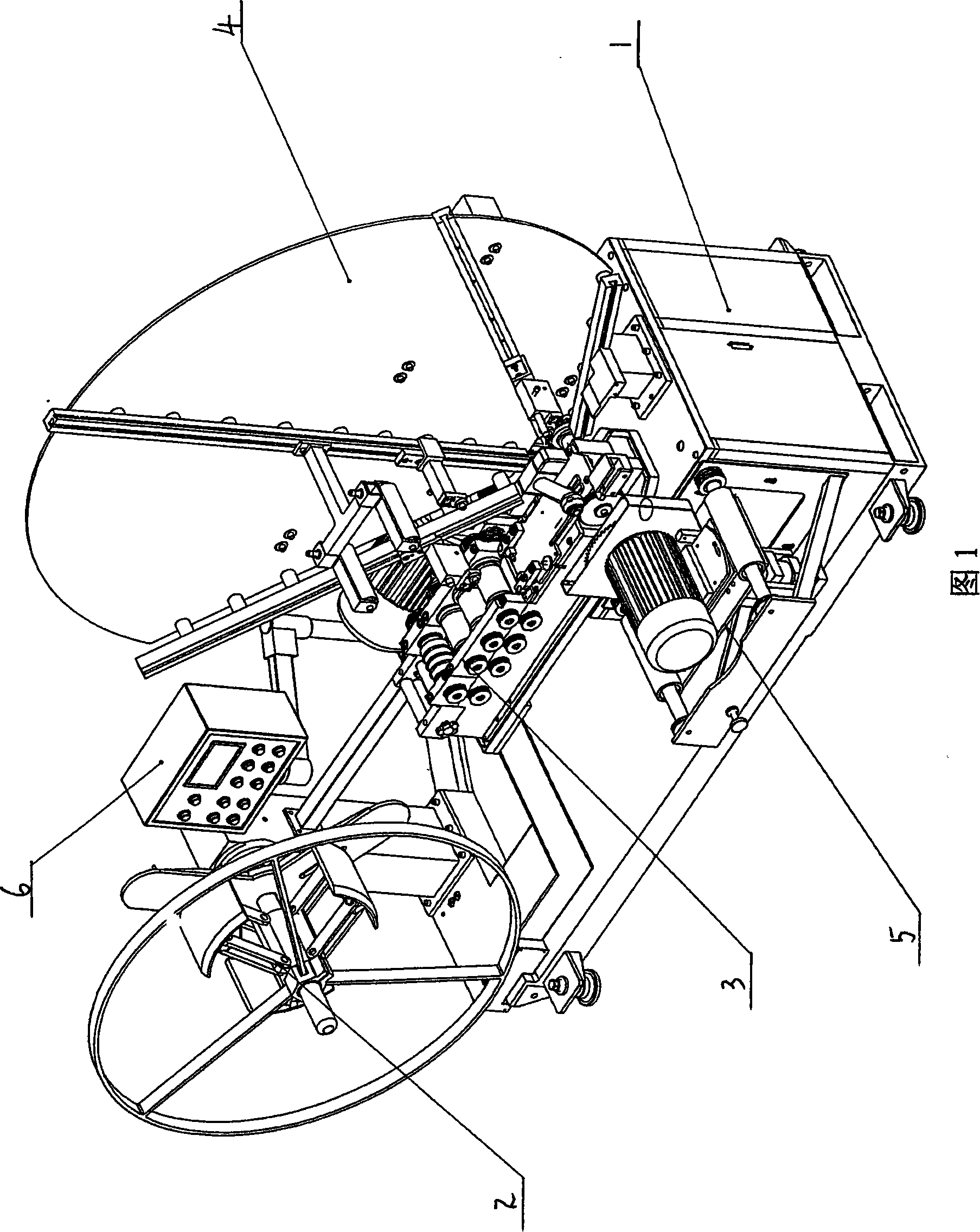

[0035] Referring to Fig. 1, the novel spiral gas pipe molding machine involved in the present invention is mainly composed of a frame 1 and a discharge rack 2 arranged on the frame 1, a bite forming unit 3, a mold frame 4, a cutting machine 5, and an electric control box 6 and discharge rack 7 form.

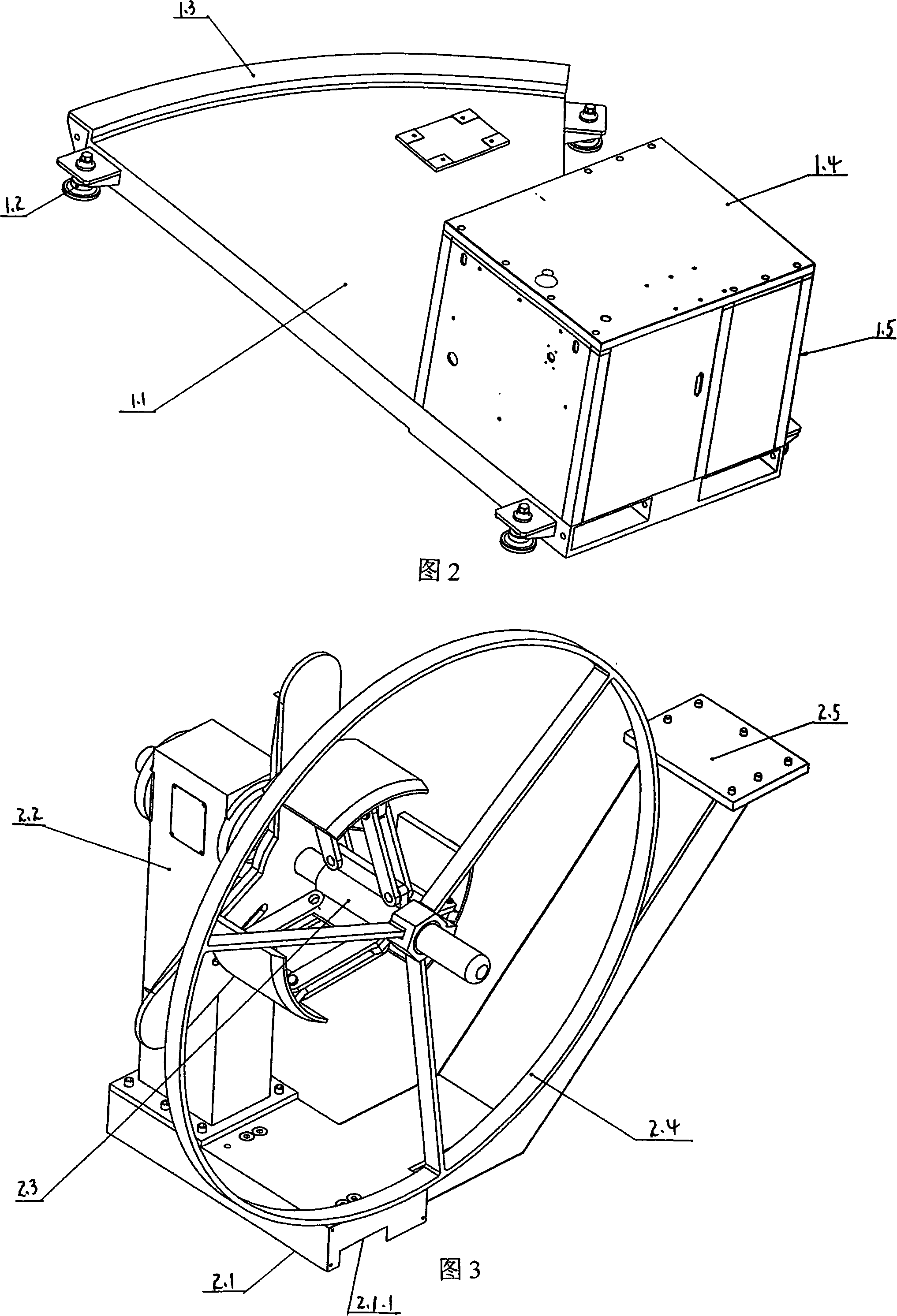

[0036] Referring to Fig. 2, the frame 1 is composed of a base plate 1.1, a horizontal adjustment seat 1.2, a discharge rack guide rail 1.3, a table top 1.4 and an electrical box 1.5. The front half of the base plate 1.1 is square, and the second half is fan-shaped. The electrical box 1.5 is fixedly installed upward on the front half of the base plate 1.1, and the table top 1.4 is fixedly installed on the top of the electrical box 1.5 for installing the bite forming unit 3. The discharge rack guide rail 1.3 is arc-shaped, and the discharge rack guide rail 1.3 is upwardly arranged on the rear edge of the second half of the base plate 1.1 for installing the discharge rack 2 . There...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com