Fabric weft setting or weft setting and pattern setting system and method

A fabric and flower shape technology, which is applied to the system of flower shape skew and flower shape bending, fabric weft or whole weft and flower system, weft bending, and weft skew. Applicable textile types are limited and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

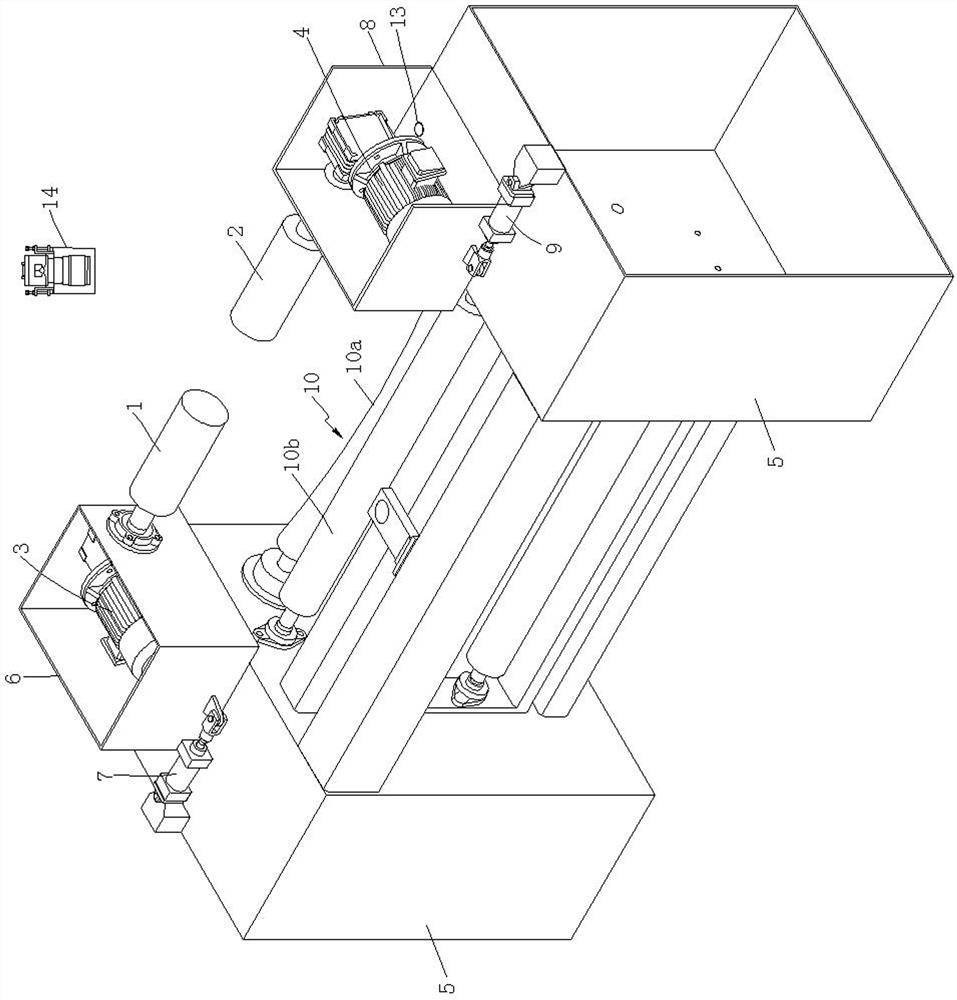

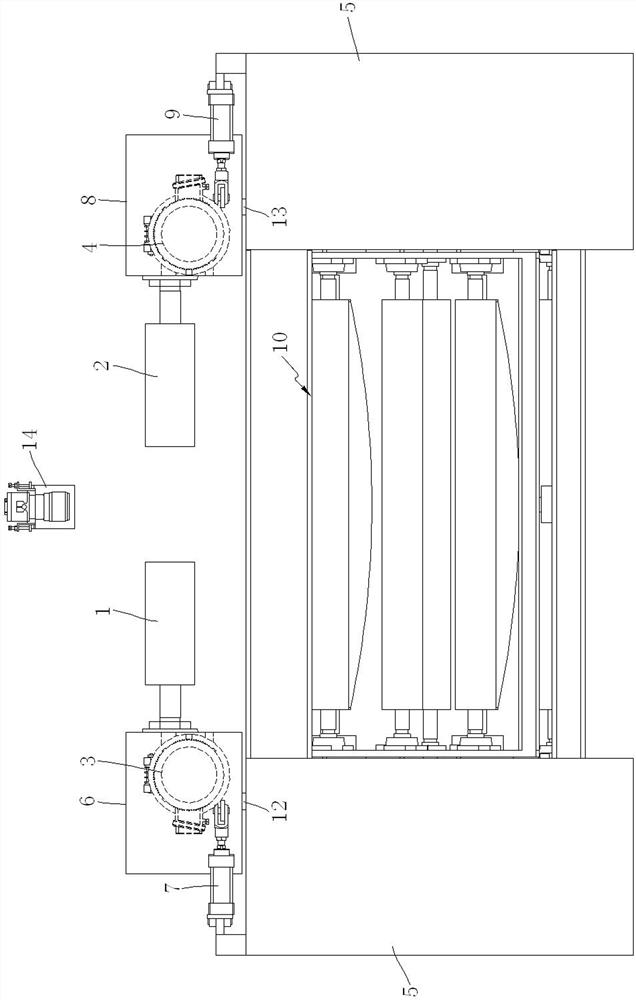

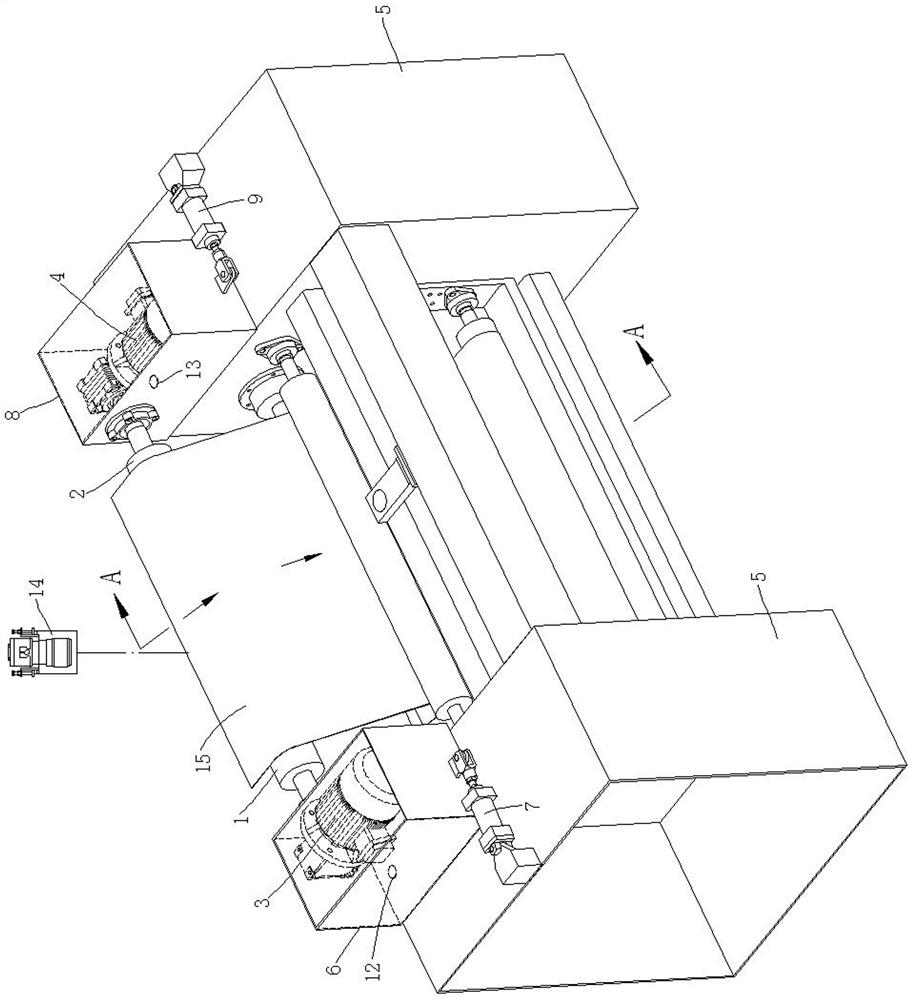

Image

Examples

Embodiment approach

[0063] As a preferred embodiment of the present invention, the first driving roller 1 and the second driving roller 2 are friction rollers with a friction surface on the outer periphery, for example, a commercially available outer peripheral surface has a larger friction coefficient such as a rubber surface The friction roller or the metal friction roller or the needle-faced roller with needles or the friction roller coated with rubber matte or thorny fur on the outer periphery. The diameter of the roller is preferably 20 to 450 mm.

[0064] As a preferred embodiment of the present invention, such as Figure 4 As shown, the fabric weft or weft and flower system also includes an expanding mechanism 11 for fabric expansion, and the expanding mechanism 11 is placed on the first driving roller 1 and the second driving roller along the fabric running route. 2 in front. The widening mechanism 11 shown in the figure is located in front of several straightening rollers 10. In the pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com