Preparation method and application of functional reconstituted tobacco

A technology for reconstituting tobacco leaves and functional type, applied in the field of tobacco, can solve the problems of slag removal, maintenance, and change of style characteristics, etc., and achieves the effects of maintaining characteristic aroma, solving high slag removal rate, and increasing action force.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

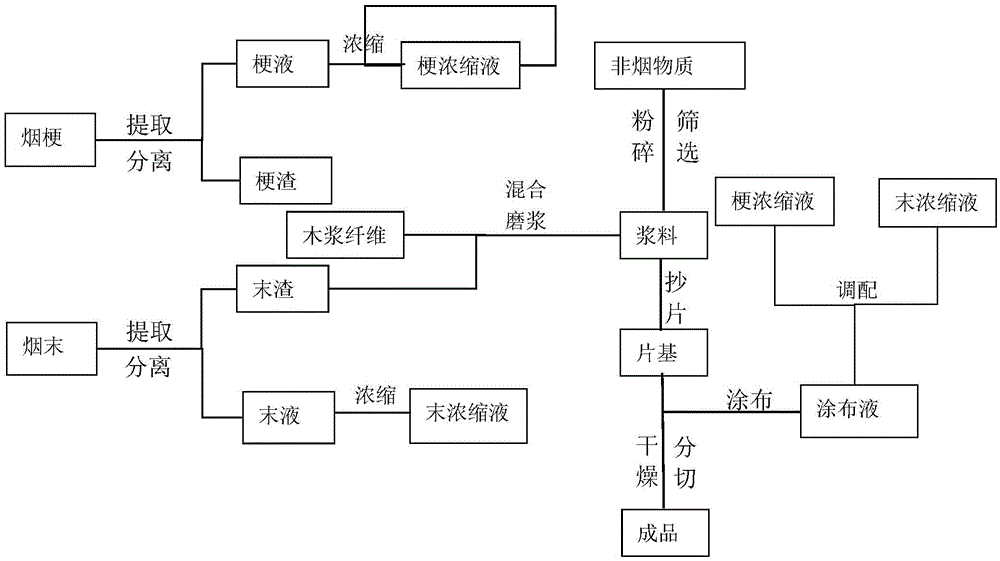

[0040] like figure 1 Shown, a kind of preparation method of functional reconstituted tobacco leaf comprises the following steps:

[0041] 1) Add the waste tobacco leaves into clean water at a solid-to-liquid ratio of 1:8, soak and extract at a temperature of 85°C, soak and extract for 30 minutes, and obtain mixed tobacco powder extract and tobacco powder after solid-liquid separation of the mixture slag;

[0042] 2) Add the tobacco stems into clean water according to the solid-to-liquid ratio of 1:8, soak and extract at a temperature of 85°C, soak and extract for 30 minutes, and obtain the tobacco stem extract and stem residue after solid-liquid separation of the mixture;

[0043] 3) defibrate the stalks through a fiberizing machine to obtain stalks;

[0044] 4) After mixing the tobacco powder in step 1) and the stem slag in step 3), add wood pulp fiber with a mass fraction of 10%, and refine the mixture. 3%;

[0045] 5) Grinding and screening the mugwort leaves, the parti...

Embodiment 2

[0059] like figure 1 Shown, a kind of preparation method of functional reconstituted tobacco leaf comprises the following steps:

[0060] 1) Add the waste tobacco leaves into clean water at a solid-to-liquid ratio of 1:6, soak and extract at a temperature of 65°C, soak and extract for 50 minutes, and obtain mixed tobacco powder extract and tobacco powder after solid-liquid separation of the mixture slag;

[0061] 2) Add the tobacco stems into clean water at a solid-to-liquid ratio of 1:8, soak and extract at a temperature of 90°C, soak and extract for 20 minutes, and separate the mixture from solid to liquid to obtain tobacco stem extracts and stem residues;

[0062] 3) defibrate the stalks through a fiberizing machine to obtain stalks;

[0063] 4) After mixing the tobacco powder in step 1) and the stem slag in step 3), add wood pulp fiber with a mass fraction of 15%, and refine the mixture. 3%;

[0064] 5) Grinding and screening the agarwood, the particle size of the powd...

Embodiment 3

[0074] like figure 1 Shown, a kind of preparation method of functional reconstituted tobacco leaf comprises the following steps:

[0075] 1) Add the waste tobacco leaves into clean water at a solid-to-liquid ratio of 1:12, soak and extract at a temperature of 75°C, soak and extract for 50 minutes, and obtain mixed tobacco powder extract and tobacco powder after solid-liquid separation of the mixture slag;

[0076] 2) adding clean water to the tobacco stems at a solid-to-liquid ratio of 1:10, soaking and extracting at a temperature of 60°C, soaking and extracting for 50 minutes, and obtaining the tobacco stem extract and stem residue after solid-liquid separation of the mixture;

[0077] 3) defibrate the stalks through a fiberizing machine to obtain stalks;

[0078] 4) After mixing the tobacco powder in step 1) and the stem slag in step 3), add wood pulp fiber with a mass fraction of 5%, and refine the mixture. 3%;

[0079] 5) Grinding and screening the chrysanthemum and li...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com