Foam forming method for completely biological degradable plastic tubleware and drinking ware

A technology of biodegradable plastics and foam molding, which is applied in the field of international patent classification C08L97/00 "compositions containing lignin materials", can solve problems such as unseen production, achieve easy recycling and treatment, and have broad market prospects. Wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

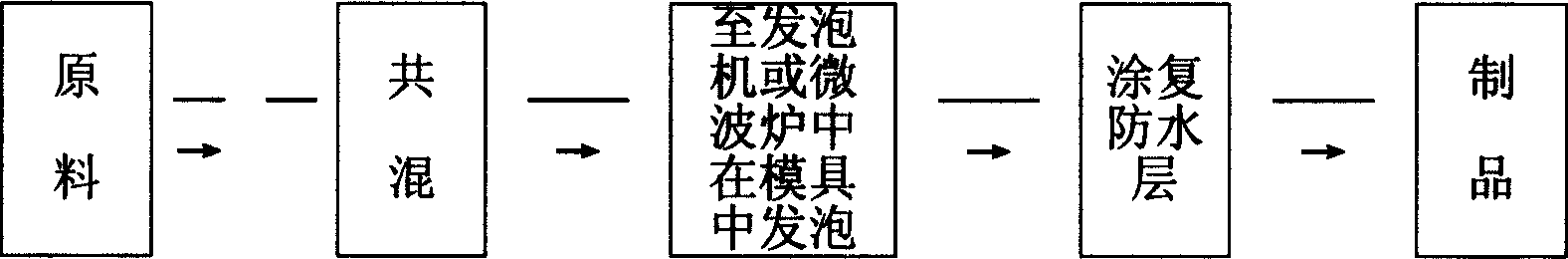

Image

Examples

Embodiment 1

[0018] Embodiment 1: 800 parts of corn flour, 60 parts of paper pulp, 60 parts of PVA, 50 parts of rice husk powder, 30 parts of plasticizer, and 300 parts of water are added; stir evenly in the mixer, after metering, send into the foaming machine In the mold, foam at 150-160°C for 3 minutes, and then apply a waterproof layer to obtain the product.

Embodiment 2

[0019] Embodiment 2: 800 parts of potato starches, 50 parts of PVA, 50 parts of paper pulp, 100 parts of orange stalk powder, 30 parts of plasticizers, 280 parts of water; Foaming, stay at 160°C for 3 minutes to foam, the product is coated with polyamide waterproofing agent, dried to obtain the finished product, and sent to the finished product warehouse.

Embodiment 3

[0020] Embodiment 3: 800 parts of cassava starch, 60 parts of PVA, 40 parts of paper pulp, filler: 100 parts of rice husk powder or orange stalk powder, 30 parts of plasticizers, 300 parts of water; Mix in blender, send into micro-skin furnace formula In the mold of the foaming machine, foam at 150-160°C for 1 minute. After the product is coated with a strong amine waterproof layer, the product is dried and put into storage.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com