High-throughput efficient 2D net-shaped ultrafine nanofiber oil-water separation material and preparation method thereof

A two-dimensional network, nanofiber technology, applied in the field of high-efficiency and high-flux oil-water separation materials and their preparation, can solve the problems of easy shedding, reduced flux, short length of cellulose nanofibers, etc. High rate and good pore connectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] A preparation method of high-efficiency and high-throughput two-dimensional network ultrafine nanofiber oil-water separation material:

[0025] 1) Sodium chloride is dissolved in N,N-dimethylacetamide, stirred by a magnetic stirrer for 10min, ultrasonically ultrasonicated for 30min, the content of sodium chloride is 0.0001twt% of the total mass of the polymer solution, and then the granular Ethylene-vinyl alcohol copolymer, molecular weight 2×10 7 , added to N,N-dimethylacetamide dissolved with sodium chloride, stirred for 2 hours under 60°C water bath conditions, to obtain a uniform and stable polymer solution, the mass concentration of ethylene-vinyl alcohol copolymer in the solution was 0.001wt %, the viscosity of the resulting solution is 1mPa·s.

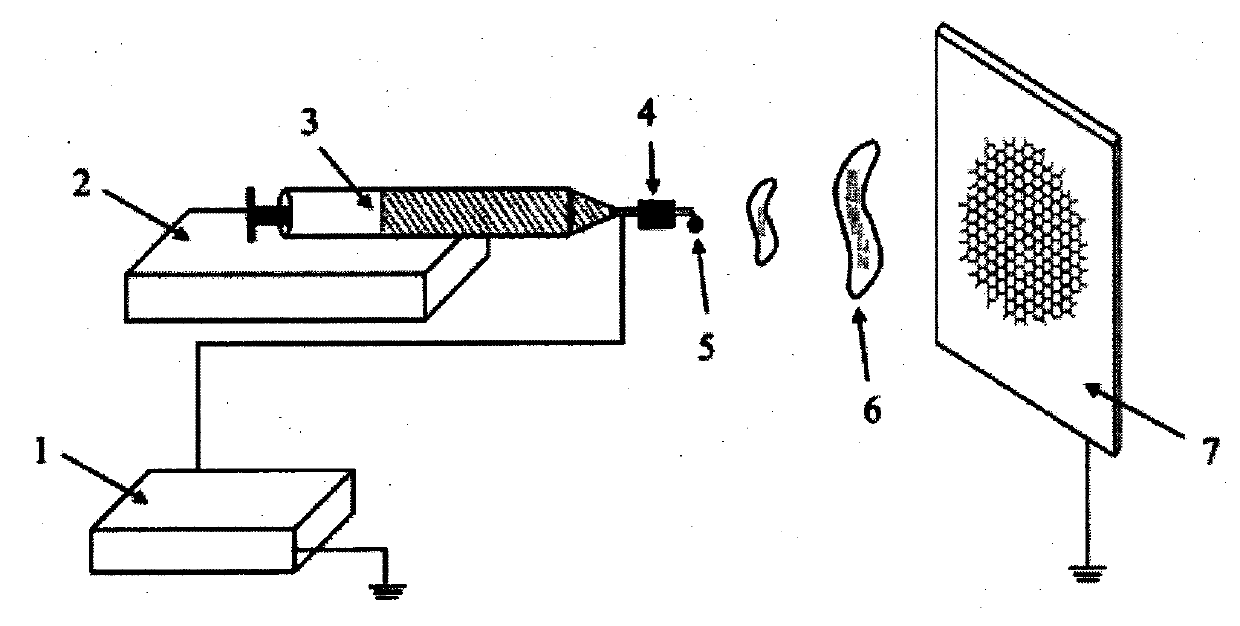

[0026] 2) use figure 1In the device shown, the polymer solution obtained above is transported to the spinneret of the injection device 3 through the liquid supply system 2, the injection device is connected to a DC high...

Embodiment 2

[0028] A preparation method of high-efficiency and high-throughput two-dimensional network ultrafine nanofiber oil-water separation material:

[0029] 1) Sodium dodecylbenzenesulfonate is dissolved in a mixed solvent of N,N-dimethylformamide and acetone, the mass ratio of N,N-dimethylformamide and acetone is 3:2, magnetically stirred Stir for 90min with a sonicator, ultrasonically for 20min, the content of sodium dodecylbenzenesulfonate is 0.1wt% of the total mass of the polymer solution, and then the powdered polyvinylidene fluoride high polymer with a molecular weight of 5.0×10 5 , added to the mixed solvent of N, N-dimethylformamide and acetone dissolved with sodium dodecylbenzenesulfonate, and stirred at room temperature for 14 hours to obtain a uniform and stable polymer solution. Polyvinylidene fluoride in the solution The mass concentration is 1.5wt%, and the viscosity of the obtained solution is 350mPa·s.

[0030] 2) use figure 1 In the shown device, the polymer solu...

Embodiment 3

[0032] A preparation method of high-efficiency and high-throughput two-dimensional network ultrafine nanofiber oil-water separation material:

[0033] 1) Dissolve silver nitrate in tetrahydrofuran, stir with a magnetic stirrer for 20 minutes, and ultrasonically perform 20 minutes with an ultrasonic instrument. The content of silver nitrate is 0.002wt% of the total mass of the polymer solution, and then the granular polystyrene polymer with a molecular weight of 1.0 ×10 7 , added to the tetrahydrofuran solvent dissolved with silver nitrate, stirred at room temperature for 6 hours to obtain a uniform and stable polymer solution, the mass concentration of polystyrene in the solution was 0.01wt%, and the viscosity of the obtained solution was 80mPa·s.

[0034] 2) use figure 1 In the shown device, the polymer solution obtained above is transported to the spinneret of the injection device 3 through the liquid supply system 2. The injection device is connected to a DC high-voltage p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com