Emulsified vegetable oil as well as preparation method and application thereof

A technology for emulsified vegetable oil and emulsified oil, which is applied in chemical instruments and methods, fat oil/fat refining, water pollutants, etc., can solve the problems of loss, high operating cost, good water solubility, etc. The effect of easy availability of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

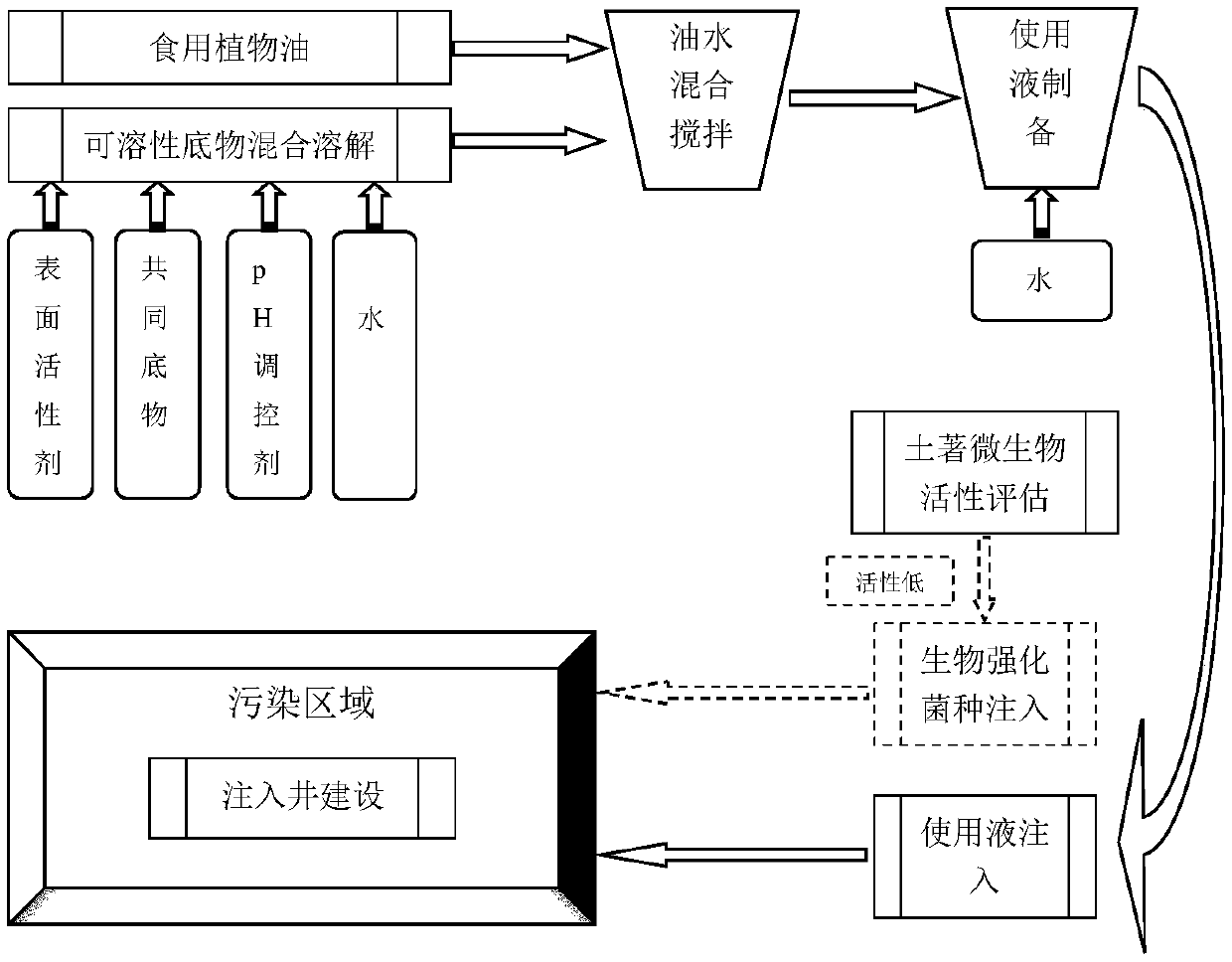

[0095] The preparation method of emulsified vegetable oil as above, comprises the steps:

[0096] (a) Surfactant, common substrate, pH adjusting agent are mixed with water;

[0097] (b) mixing and stirring the soluble substrate mixed and dissolved in step (a) with edible vegetable oil to obtain emulsified vegetable oil;

[0098] Preferably, the diameter of the oil droplets in the emulsified vegetable oil is 0.1-3 μm;

[0099]The diameter of the oil droplets in the emulsified vegetable oil is typically but not limited to, for example, 0.1 μm, 0.5 μm, 1 μm, 1.5 μm, 2 μm, 2.5 μm or 3 μm.

[0100] During the preparation of emulsified vegetable oil, the key purpose is to produce stable, non-agglomerated, sufficiently small and uniform emulsified oil droplets to form a stable oil-in-water emulsified oil preparation. The diameter of oil droplets in ideal emulsified vegetable oil should reach 0.1-3μm. The preparation of emulsion is a very mature technology in the food industry, whi...

Embodiment 1

[0128] In the former site of a chemical factory, the excessive groundwater pollutants are trichloroethane and trichloroethylene, and the target treatment area volume is 2400m 3 , the effective porosity is 0.25, the highest pollution concentration is trichloroethane 19mg / L, trichloroethylene 0.3mg / L, using this process for groundwater remediation, the specific implementation is as follows:

[0129] The emulsified vegetable oil prepared for repairing the polluted groundwater of the site is composed of the following active ingredients according to the weight ratio: soybean oil 60%, Tween 85 3%, sodium lactate 0.4%, yeast extract powder 0.12%, vitamin B-12 0.035%, Magnesium Hydroxide 0.1% and Water 36.345%.

[0130] Such as figure 1 Shown, described emulsified vegetable oil preparation method, comprises the steps:

[0131] (1) Add the above-mentioned Tween 85, sodium lactate, yeast extract powder, vitamin B-12 and magnesium hydroxide into the above-mentioned water, fully mix and...

Embodiment 2

[0142] In the former site of a chemical factory, the groundwater pollutant is cis-dichloroethylene, and the target treatment area volume is 13000m 3, the effective porosity is 0.22, and the highest pollution concentration is 15mg / L. This process is used for groundwater remediation. The specific implementation is as follows:

[0143] Prepare the emulsified vegetable oil used to restore the polluted groundwater of the site, which consists of the following active ingredients according to the weight ratio: soybean oil 40%, rapeseed oil 30%, Tween 60 4%, glycerol monooleate 4%, sodium bicarbonate 0.2% and water 21.8%.

[0144] The method for preparing emulsified vegetable oil comprises the steps of:

[0145] (1) Add the above-mentioned Tween 60, glycerol monooleate and sodium bicarbonate into the above-mentioned water, fully mix and dissolve;

[0146] (2) Mix the soluble substrate mixed and dissolved in step (1) with the above soybean oil and rapeseed oil, and mix once with a sta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com