Chemical etching, cleaning and drying method of single-crystal silicon solar battery and integrated processing machine

A solar cell and chemical etching technology, applied in the field of chemical etching technology and cleaning, can solve the problems of difficulty in improving the cleanliness of silicon wafers, operator injury, serious pollution, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

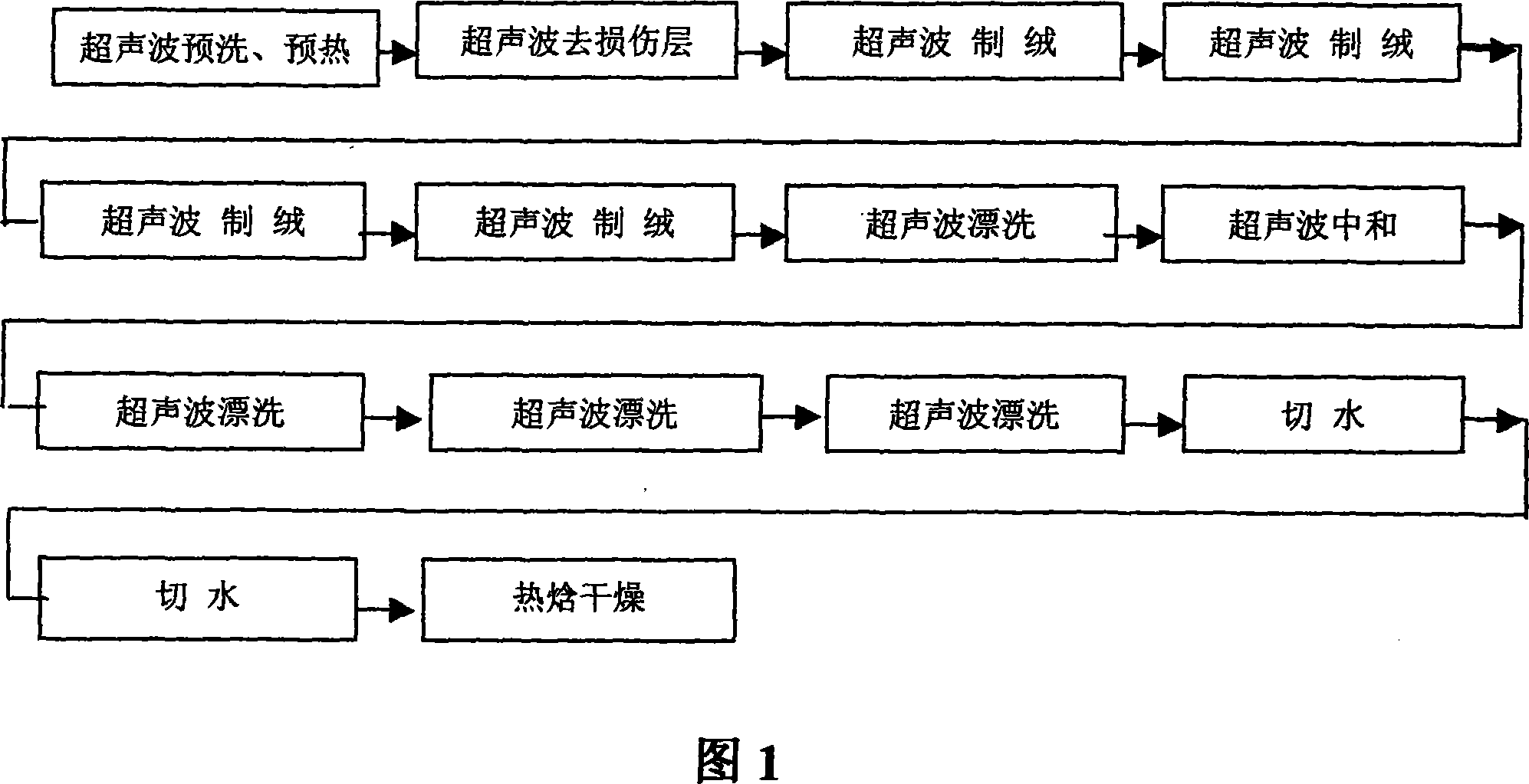

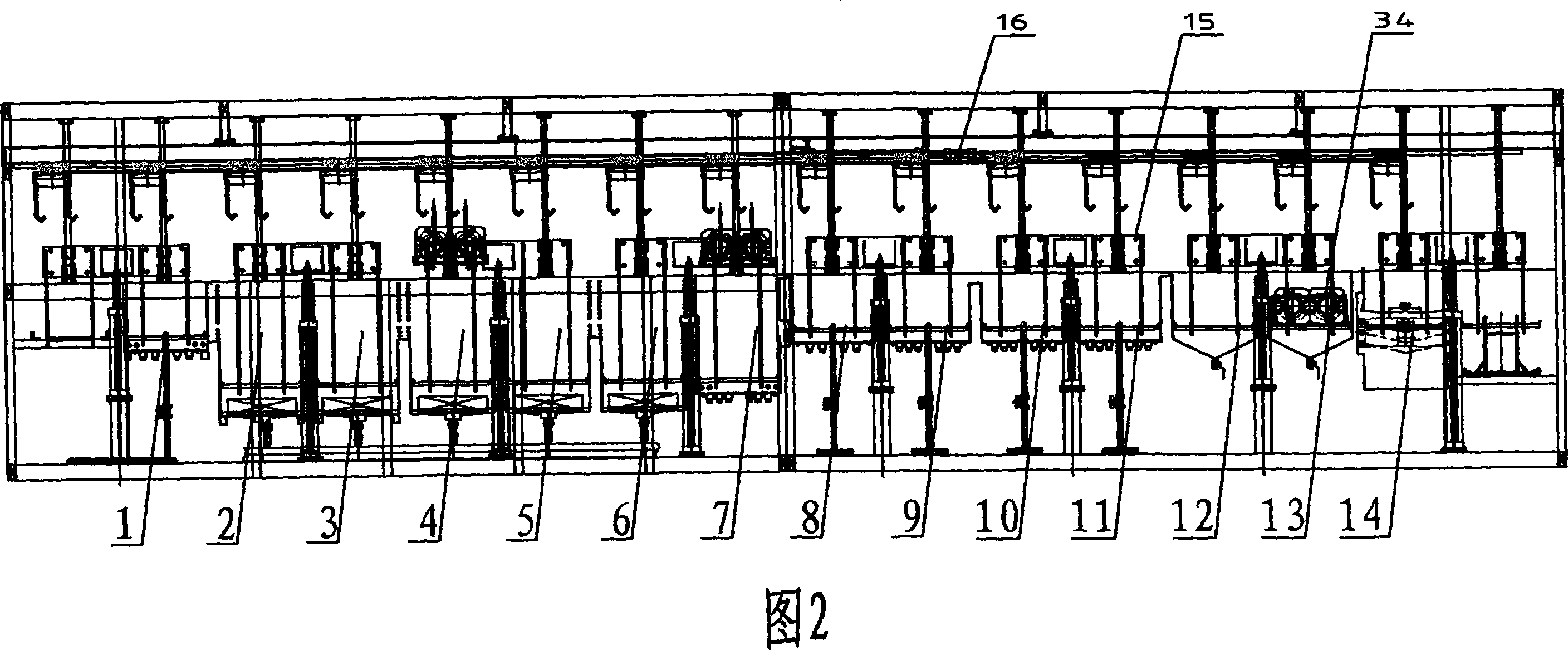

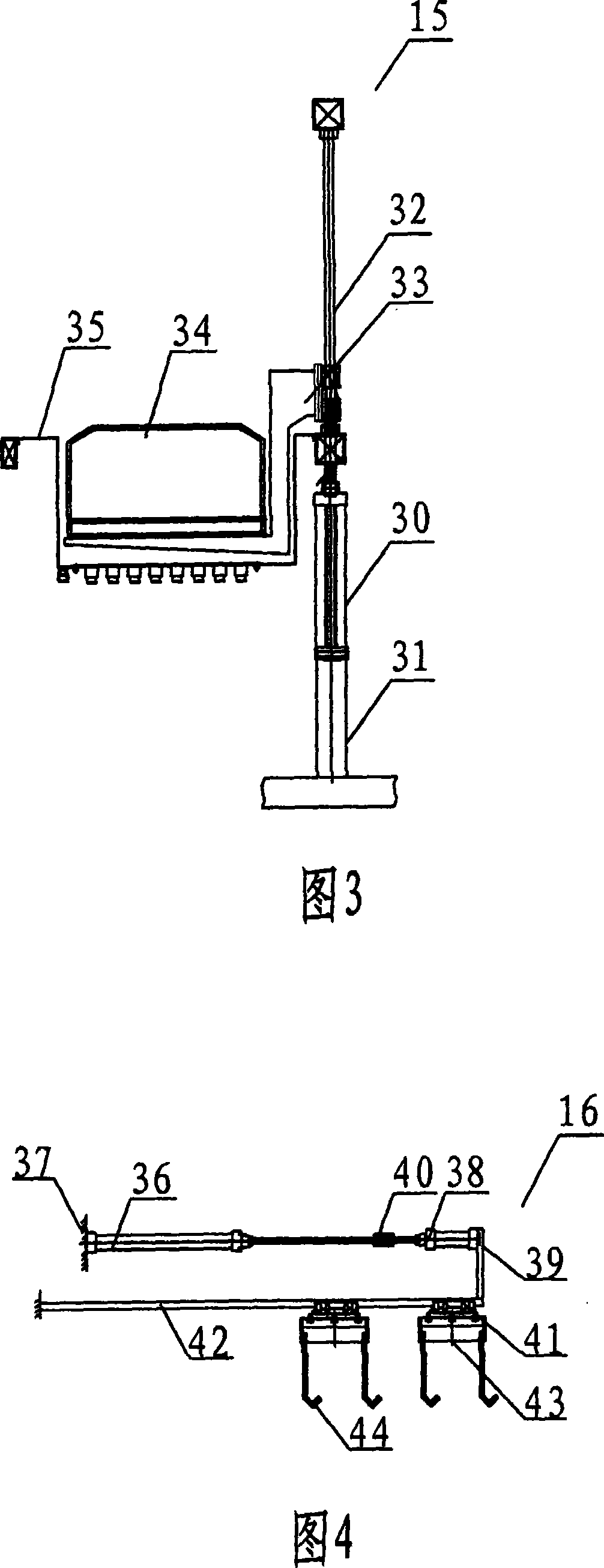

[0019] Now in conjunction with accompanying drawing, the present invention will be further described:

[0020] The method of chemical etching, cleaning and drying of monocrystalline silicon solar cells includes water, acid and alkali to participate in etching and cleaning, and its characteristics are: and ultrasonic waves participate in the etching and cleaning process; the etching, cleaning and drying are completed by the following operating procedures :

[0021] ①Ultrasonic pre-washing and pre-heating: Clean the cutting chips, coolant and other sundries on the silicon wafer with water cleaning solution, and heat the silicon wafer at room temperature to 40-50°C in the cleaning solution;

[0022] ②Ultrasonic to remove the damaged layer: Soak the silicon wafer in a 5% NaOH solution at 80-90°C for 5 minutes, and the damaged layer will be peeled off by the cavitation bubbles of the ultrasonic wave and the uniform liquid mass concentration;

[0023] ③Ultrasonic texturing treatmen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com