Synthesis method of a high-performance lithium-rich manganese-based cathode material with a cubic structure

A cathode material, lithium-rich manganese-based technology, applied in the field of synthesis of high-performance lithium-rich manganese-based cathode materials with a cubic structure, can solve the problems of restricting the development of lithium-ion batteries and poor cycle performance, and achieve excellent lithium battery performance, low cost, The effect of simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

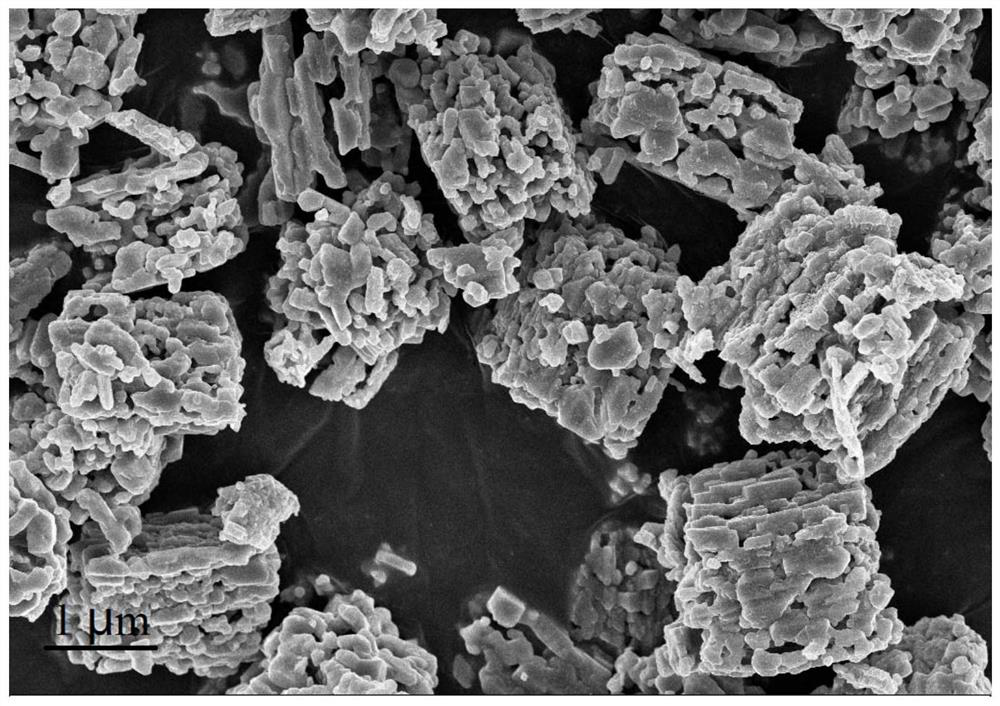

[0022] This example shows a high-performance lithium-rich manganese-based positive electrode material with a cubic structure, and the specific steps are as follows:

[0023] A method for synthesizing a high-performance lithium-rich manganese-based cathode material with a cubic structure, comprising the following steps:

[0024] (1) Cobalt sulfate, nickel sulfate, and manganese sulfate with a molar mass ratio of 1:2:7 are dissolved in deionized water, and weakly alkaline lithium acetate is added as a pH buffer to form solution A;

[0025] (2) Dissolving the two-carbon compound—dimethyl oxalate in ethanol to form solution B;

[0026] (3) Mix the solutions A and B, and synthesize the precursor of the positive electrode material with a cubic structure by the traditional hydrothermal method, wherein the hydrothermal temperature is 150°C, and the hydrothermal time is 6h;

[0027] (4) After the precursor is filtered, washed, dried, doped with lithium, pre-calcined, ground, and calci...

Embodiment 2

[0029] This example shows a high-performance lithium-rich manganese-based positive electrode material with a cubic structure, and the specific steps are as follows:

[0030] A method for synthesizing a high-performance lithium-rich manganese-based cathode material with a cubic structure, comprising the following steps:

[0031] (1) Cobalt sulfate, nickel sulfate, and manganese sulfate with a molar mass ratio of 1:2:7 are dissolved in deionized water, and weakly alkaline sodium acetate is added as a pH buffer to form solution A;

[0032] (2) Dissolving the two-carbon compound—dimethyl oxalate in ethanol to form solution B;

[0033] (3) Mix the solutions A and B, and synthesize the precursor of the positive electrode material with a cubic structure by the traditional hydrothermal method, wherein the hydrothermal temperature is 250°C, and the hydrothermal time is 18h;

[0034] (4) After the precursor is filtered, washed, dried, doped with lithium, pre-calcined, ground, and calci...

Embodiment 3

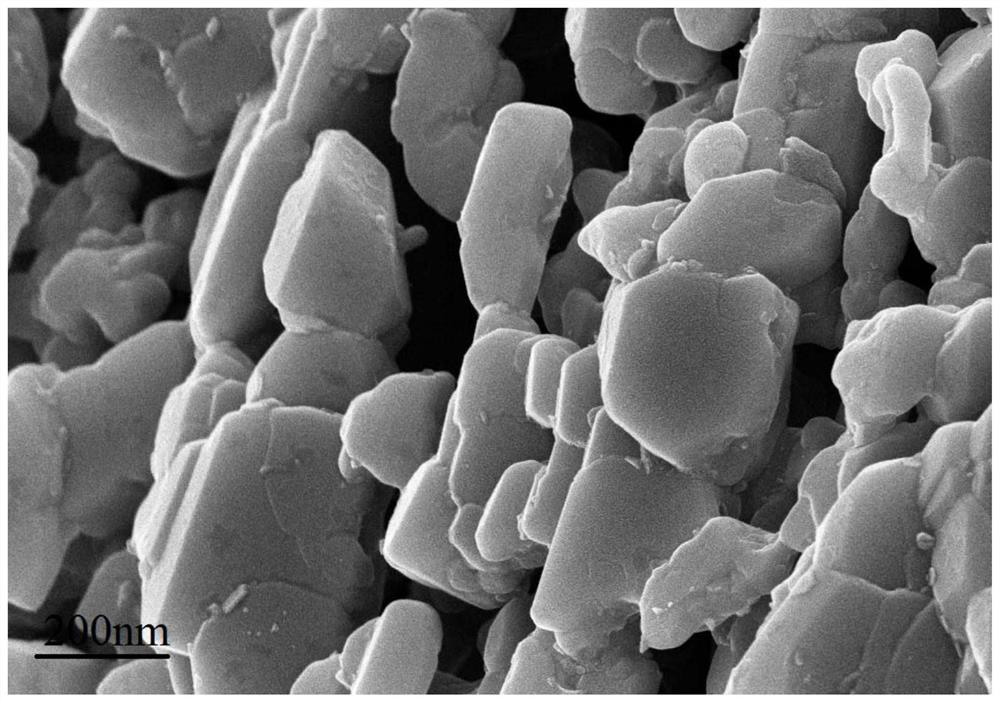

[0036] This example shows a high-performance lithium-rich manganese-based positive electrode material with a cubic structure, and the specific steps are as follows:

[0037] A method for synthesizing a high-performance lithium-rich manganese-based cathode material with a cubic structure, comprising the following steps:

[0038] (1) Cobalt sulfate, nickel sulfate, and manganese sulfate with a molar mass ratio of 1:2:7 are dissolved in deionized water, and weakly alkaline lithium acetate is added as a pH buffer to form solution A;

[0039] (2) Dissolving the two-carbon compound—dimethyl oxalate in ethanol to form solution B;

[0040] (3) Mix the solutions A and B, and synthesize the precursor of the positive electrode material with a cubic structure by the traditional hydrothermal method, wherein the hydrothermal temperature is 200°C, and the hydrothermal time is 12h;

[0041] (4) After the precursor is filtered, washed, dried, doped with lithium, pre-calcined, ground, and calc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com