A kind of porous silicon@amorphous carbon/carbon nanotube composite material and its preparation method and application

A technology of amorphous carbon and carbon nanotubes, applied in the direction of active material electrodes, structural parts, electrical components, etc., can solve problems such as the inability to build a conductive network with carbon nanotubes and porous silicon, achieve excellent lithium battery performance, facilitate industrialization, Simple and controllable preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

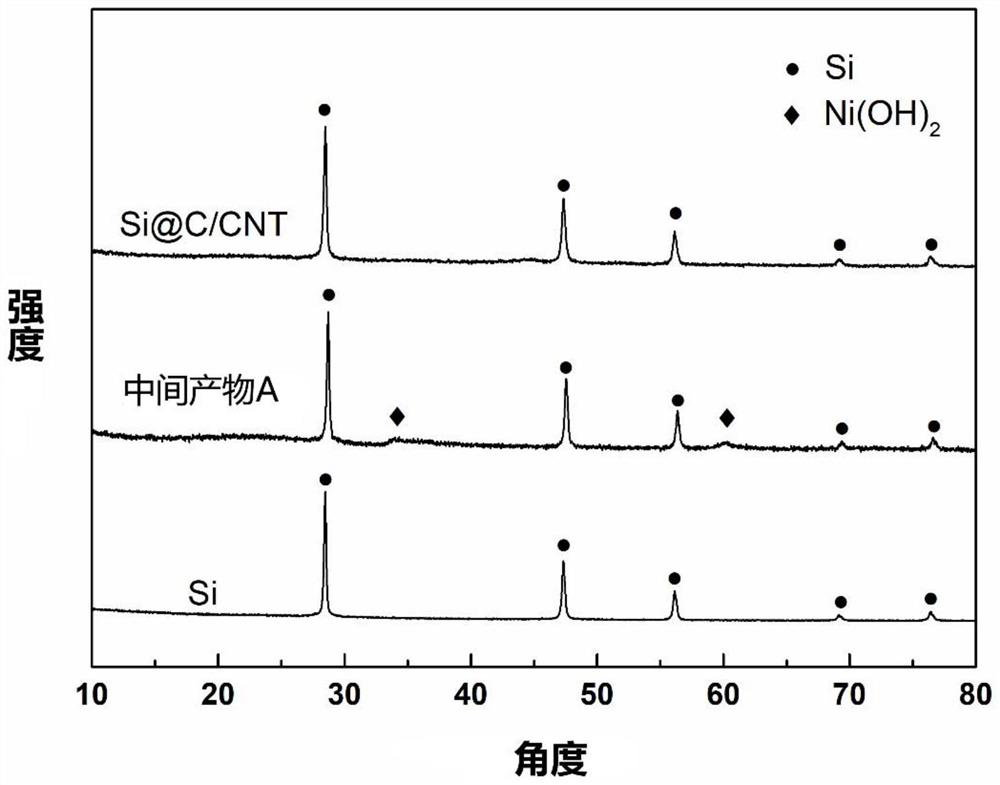

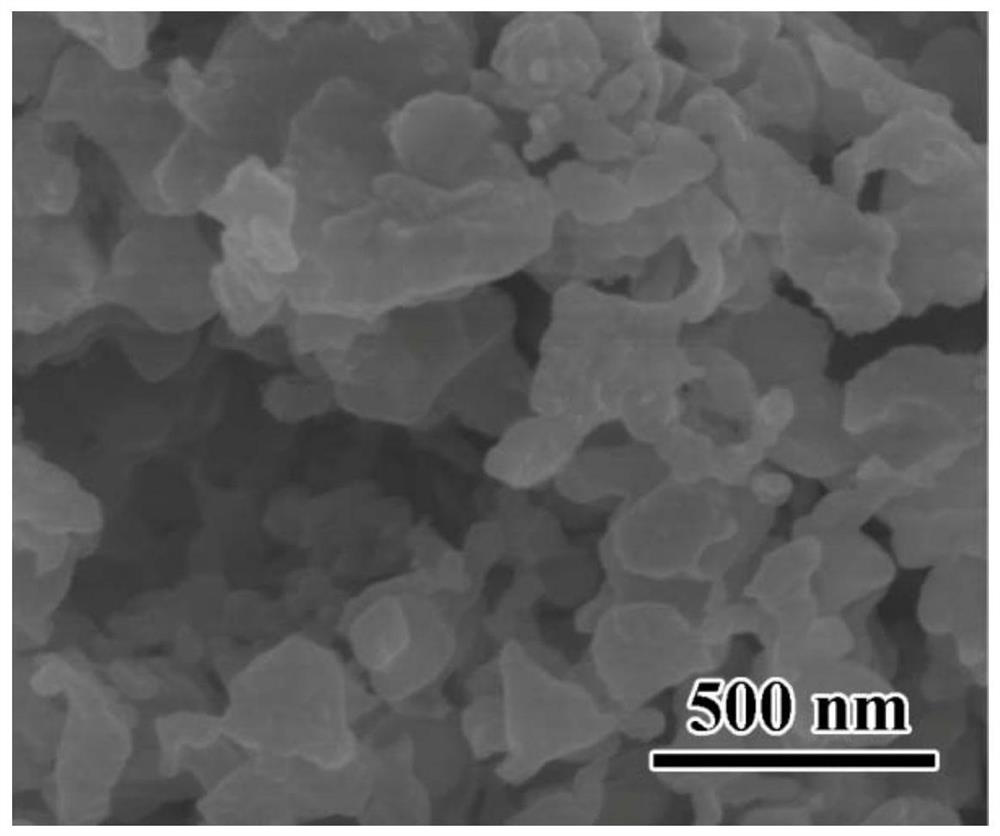

[0065] (1) Take 2g commercial Mg 2 Si is placed in a corundum boat as a raw material, and placed in a tube furnace for heat treatment. The heating rate is 20°C / min, the reaction temperature is 650°C, the reaction time is 5h, and the reaction atmosphere is air. The reacted product was placed in 0.1M hydrochloric acid and stirred for 8 hours. After the reaction, the porous silicon in the suspension was centrifuged three times with deionized water, and dried in a vacuum oven at 80° C. for later use.

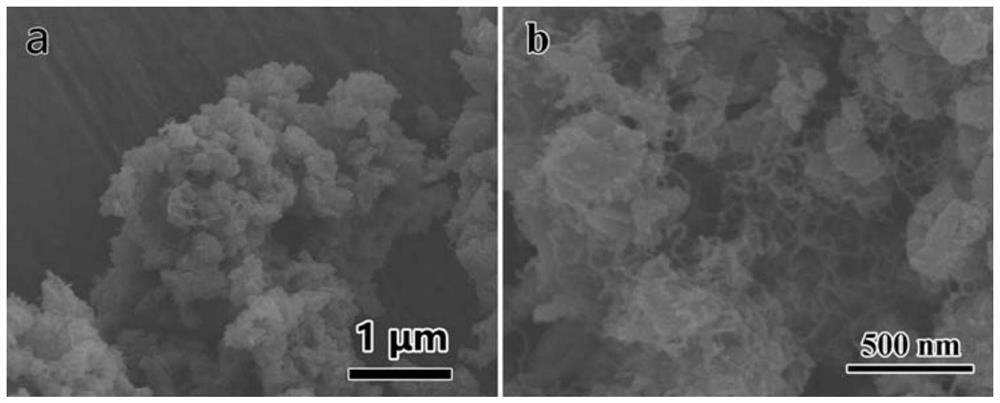

[0066] (2) The porous silicon prepared in step (1) is mixed with water according to porous silicon: nickel nitrate hexahydrate: urea=1:0.5:2.5 (molar ratio) to form a solution, and the concentration of nickel ions in the solution is 0.1mol / L , subjected to constant temperature magnetic stirring at a temperature of 80° C. for 8 hours, and finally the resulting solution was centrifuged, washed three times with water and once with ethanol, and dried in vacuum at 80° C. to obtain an in...

Embodiment 2

[0080] The preparation process is exactly the same as that in Example 1, except that the heat treatment temperature in step (3) is replaced by 450°C, and the CVD treatment temperature in step (4) is replaced by 600°C.

[0081] It can be seen through testing that the appearance of the product is similar to that of the final product prepared in Example 1.

Embodiment 3

[0083] The preparation process is exactly the same as that in Example 1, except that the heat treatment temperature in step (3) is replaced by 700°C, and the CVD treatment temperature in step (4) is replaced by 700°C.

[0084] It can be seen through testing that the appearance of the product is similar to that of the final product prepared in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com