A hollow structure ceo 2 @c Core-shell nanocomposite material and its preparation method and application

A nano-composite material, hollow structure technology, applied in nanotechnology, structural parts, nanotechnology and other directions, to achieve the effect of simple preparation method, low energy consumption, and safe preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

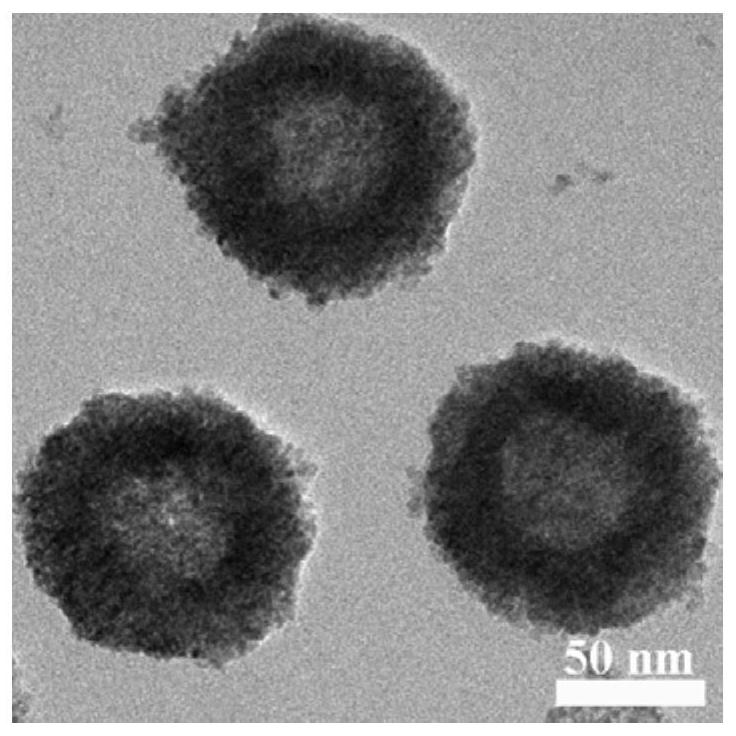

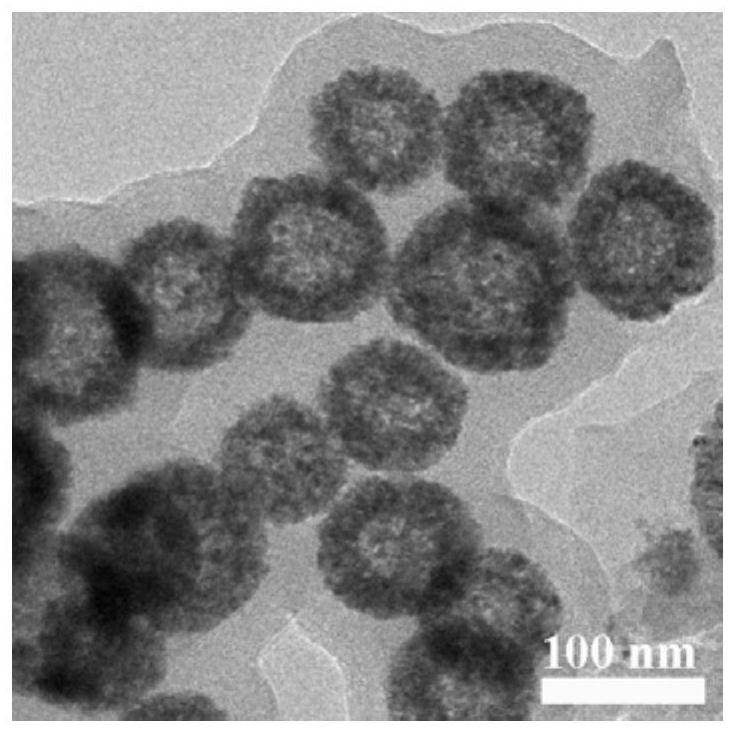

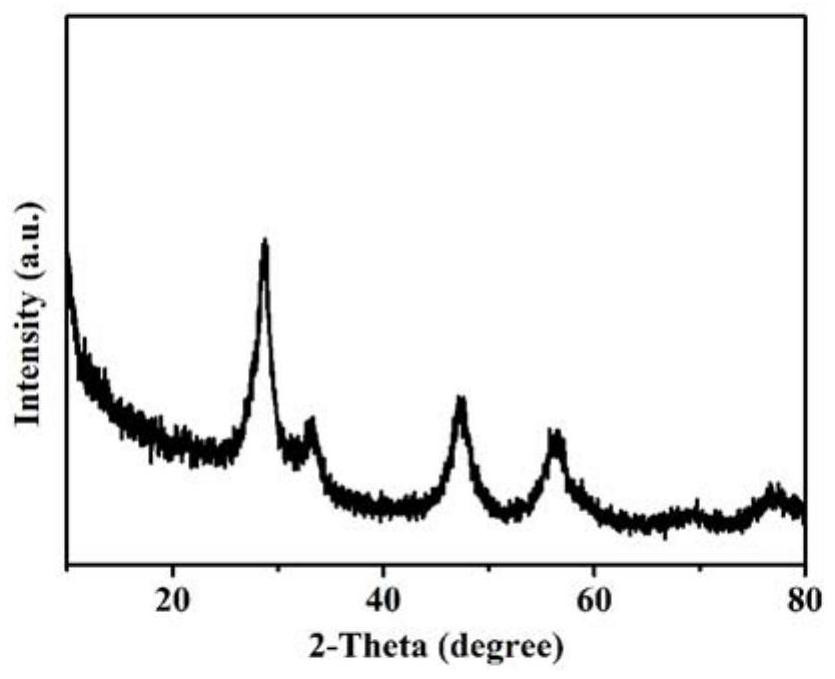

[0036] As introduced in the background technology, in the prior art about CeO 2 There are certain deficiencies in the composite material and preparation method. In order to solve the above technical problems, in one or some embodiments of the present disclosure, a hollow structure CeO 2 The preparation method of @C core-shell nanocomposite material, comprises the following steps:

[0037] (1)CeO 2 Preparation of hollow spheres: with Ce(NO 3 ) 3 ·6H 2 O is the cerium source, ethylene glycol is used as the solvent, PVP is used as the template, and hydrochloric acid solution is added to the system for solvothermal reaction to prepare CeO 2 hollow ball;

[0038] (2) Hollow spherical CeO 2 Preparation of @C core-shell nanocomposites:

[0039] ①CeO 2 Ultrasonic dispersion in a mixed solution of water and ethanol;

[0040] ②NH 3 ·H 2 O, resorcinol, formaldehyde join step 1. in the gained suspension solution;

[0041] ③ stirring the suspension solution prepared in step ②; ...

Embodiment 1

[0075] (1) 0.5g Ce(NO 3 ) 3 ·6H 2 O was added to 15 mL of ethylene glycol, and stirred at room temperature for 0.5 h;

[0076] (2) Add 0.5g of PVP to the solution obtained in step (1), and stir at room temperature for 15 minutes;

[0077] (3) Add 1 mL of 1mol / L HCl to the solution obtained in step (2), and continue stirring for 15 min;

[0078] (4) the mixed solution that step (3) is obtained is transferred in the autoclave of the polytetrafluoroethylene liner of 20mL;

[0079] (5) Tighten the autoclave in step (4) and put it in an oven, and keep it warm at 160° C. for 3 hours; after the solvent heat treatment, naturally cool the autoclave to room temperature;

[0080] (6) Centrifuge the precipitate obtained in step (5), wash with distilled water and ethanol three times respectively, dry in a blast drying oven at 80°C for 24 hours, and grind to obtain CeO 2 powder;

[0081] (7) with the CeO obtained in step (6) 2 Disperse 100mg of powder in a mixed solution of 10mL deio...

Embodiment 2

[0087] (1) 0.5g Ce(NO 3 ) 3 ·6H 2 O was added to 15 mL of ethylene glycol, and stirred at room temperature for 0.5 h;

[0088] (2) Add 0.5g of PVP to the solution obtained in step (1), and stir at room temperature for 15 minutes;

[0089] (3) Add 0.5 mL of 1mol / L HCl to the solution obtained in step (2), and continue stirring for 15 min;

[0090] (4) the mixed solution that step (3) is obtained is transferred in the autoclave of the polytetrafluoroethylene liner of 20mL;

[0091] (5) Tighten the autoclave in step (4) and put it in an oven, and keep it warm at 160° C. for 3 hours; after the solvent heat treatment, naturally cool the autoclave to room temperature;

[0092] (6) Centrifuge the precipitate obtained in step (5), wash with distilled water and ethanol three times respectively, dry in a blast drying oven at 80°C for 24 hours, and grind to obtain CeO 2 powder;

[0093] (7) with the CeO obtained in step (6) 2 Disperse 100mg of powder in a mixed solution of 10mL de...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com