A kind of production method of battery grade cobalt sulfate crystal

A production method, cobalt sulfate technology, applied in the field of metallurgy, can solve the problems of high storage and transportation costs, large consumption, and deteriorating operating environment, and achieve the effects of reducing storage and transportation costs, improving cobalt grades, and saving raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

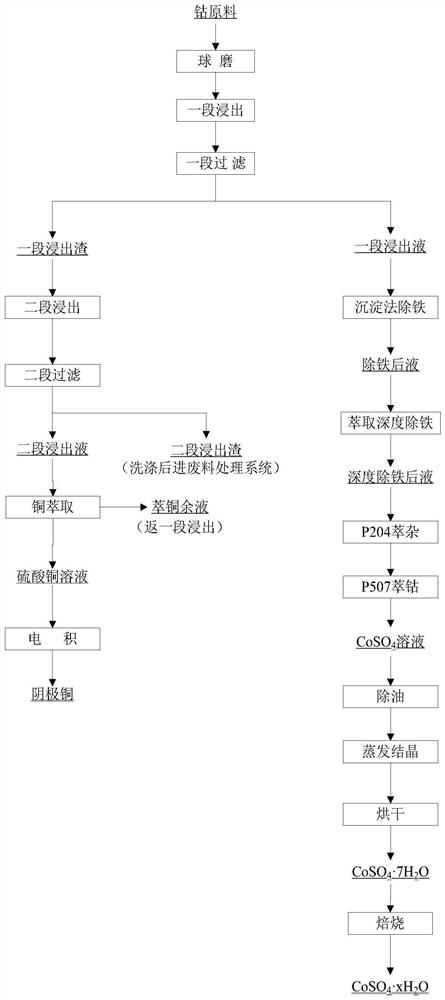

[0047] This embodiment uses copper oxide cobalt ore to prepare cobalt sulfate crystals. For details, please refer to figure 1 ,Proceed as follows:

[0048] (1) Pretreatment: The copper-cobalt oxide ore is crushed and ball-milled to form a pulp, and the mass ratio of particles smaller than 200 meshes in the pulp to all particles is 92%.

[0049] (2) Two-stage leaching:

[0050] In one-stage leaching, after the copper oxide ore is ball-milled and slurried, copper extraction raffinate, concentrated sulfuric acid and a small amount of SO are added 2 Carry out one-stage leaching, the leaching temperature is 80°C, the leaching time is 4h, the liquid-solid ratio is 5 / 1, the stirring speed is 180r / min, the end point pH=3.5, after the end of the one-stage leaching, carry out one-stage filtration, and the one-stage leaching solution enters the precipitation method to remove iron Process, the first-stage leaching residue enters the second-stage leaching process; the second-stage leachi...

Embodiment 2

[0064] (1) Pretreatment: the copper-cobalt oxide ore is crushed and ball-milled to form a pulp, and the mass ratio of particles smaller than 200 meshes in the pulp to all particles is 95%.

[0065] (2) Two-stage leaching:

[0066] In one-stage leaching, after copper oxide ore is ball-milled and slurried, copper extraction raffinate, concentrated sulfuric acid and a small amount of Na 2 S 2 o 5 Carry out one-stage leaching, the leaching temperature is 120°C, the leaching time is 2h, the liquid-solid ratio is 10 / 1, the stirring speed is 280r / min, the end point pH=3.5, after the end of the one-stage leaching, carry out one-stage filtration, and the one-stage leachate enters the precipitation method to remove iron Process, the first-stage leaching residue enters the second-stage leaching process; the second-stage leaching temperature is 120°C, the leaching time is 2h, the liquid-solid ratio is 10 / 1, the stirring speed is 280r / min, the end point pH is 2.0, and a sufficient amount...

Embodiment 3

[0080] (1) Pretreatment: The copper-cobalt oxide ore is crushed and ball-milled to form a pulp, and the mass ratio of particles smaller than 200 meshes in the pulp to all particles is 93%.

[0081] (2) Two-stage leaching:

[0082] In one-stage leaching, after copper oxide ore is ball-milled and slurried, copper extraction raffinate, concentrated sulfuric acid and a small amount of Na 2 SO 3Carry out one-stage leaching, the leaching temperature is 60°C, the leaching time is 8h, the liquid-solid ratio is 4 / 1, the stirring speed is 220r / min, the end point pH=3.0, after the end of the one-stage leaching, carry out one-stage filtration, and the one-stage leachate enters the precipitation method to remove iron process, the first-stage leaching residue enters the second-stage leaching process; the second-stage leaching temperature is 60°C, the leaching time is 8h, the liquid-solid ratio is 4 / 1, the stirring speed is 220r / min, the end point pH=1.8, and a sufficient amount of Na 2 SO...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com