Chlorination leaching method of laterite sulfurized precipitate

A technology of chlorination leaching and precipitation, applied in the field of metallurgy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

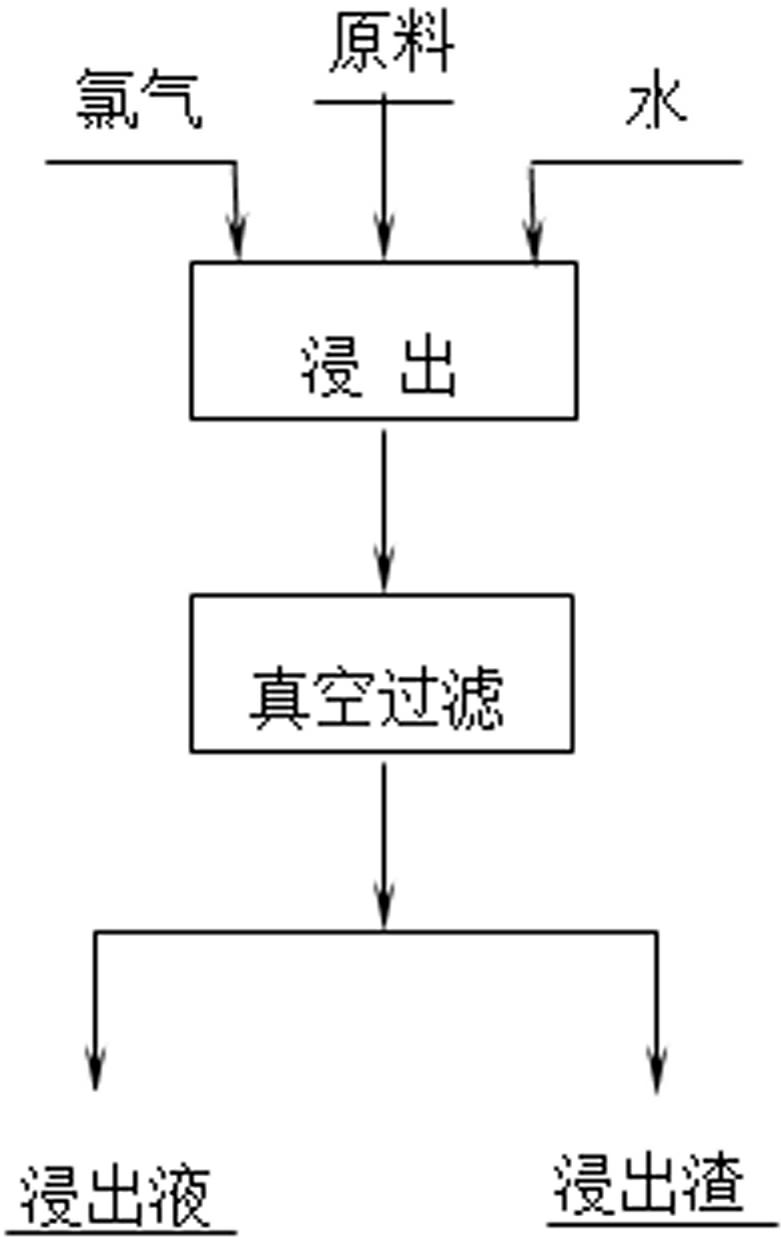

[0016] The present invention and its effects will be further described below in conjunction with the accompanying drawings.

[0017] A method for chlorination and leaching of laterite sulfide precipitates. Through chlorination leaching, the influent and effluent enriched in metallic nickel can be directly entered into the nickel production system. The details of each section of the process flow are as follows:

[0018] (1) Mix the purchased minerals with water at a mass ratio of 2:1, 3:1, 4:1, 5:1 or 6:1, and feed in a pressure of 0.1, 0.2, 0.2, 0.4 or 0.5 Mpa chlorine gas;

[0019] (2) Control chlorine gas leaching: control the leaching liquid-solid ratio to 2:1, 3:1, 4:1, 5:1 or 6:1, the leaching temperature is 70°C, 60°C or 80°C, and the leaching potential is 450mv, 460mv, 470mv 480mv, the leaching time is 2, 3 or 4h, the aqueous solution containing 30-50g / L copper in the leaching stock solution.

[0020] In the present invention, chlorine gas transfers electrons through ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com