Application of integrated COP nanosheet arrays as monolithic peroxidase-like enzymes

A peroxidase and nanosheet array technology, applied in the field of simulated enzymes, can solve the problems of cumbersome recycling process and difficult recycling, achieve convenient recycling and reuse, excellent recycling effect, increase surface area and utilization rate Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

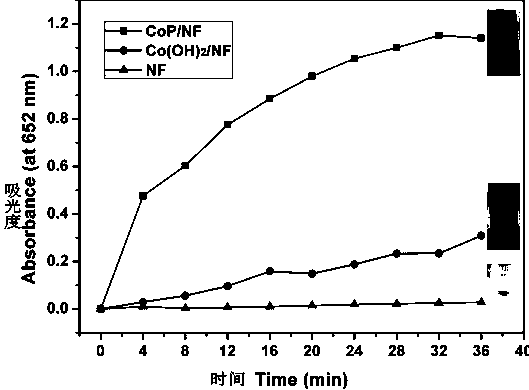

[0039] The preparation method of the integrated CoP nanosheet array as a monolithic peroxidase comprises the following steps:

[0040] 1) Cut the commercial nickel foam into a square of 1cm×1cm, soak it with 37% hydrochloric acid for 30 minutes and ultrasonically clean it with deionized water for 10 minutes, then move it to a 60°C constant temperature drying oven to dry to obtain pure foam nickel;

[0041] 2) Dissolve 1.4055g of cobalt sulfate and 0.3g of urea into 30mL of deionized water, and mix well by stirring at room temperature for 10min;

[0042] 3) Put the treated nickel foam (30 pieces) and the above solution in a hydrothermal reaction kettle for 12 hours at 80°C to obtain Co(OH) 2 Nanosheet array modified nickel foam composite;

[0043] 4) Rinse the above complex with deionized water, and dry it in an oven at 60°C. Dry Co(OH) 2 / NF tablets (6 pieces) and 300mg sodium hypophosphite were respectively placed in two adjacent porcelain boats (the porcelain boats were pla...

Embodiment 2

[0048] The preparation method of the integrated CoP nanosheet array as a monolithic peroxidase comprises the following steps:

[0049] 1) Cut the commercial nickel foam into a square of 1cm×1cm, soak it with 37% hydrochloric acid for 30 minutes and ultrasonically clean it with deionized water for 10 minutes, then move it to a 60°C constant temperature drying oven to dry to obtain pure foam nickel;

[0050] 2) Dissolve 1.4055g of cobalt sulfate and 0.9g of urea into 60mL of deionized water, and mix well by stirring at room temperature for 20min;

[0051] 3) Put the treated nickel foam (30 pieces) and the above solution in a hydrothermal reaction kettle for 24 hours at 150°C to obtain Co(OH) 2 Nanosheet array modified nickel foam composite;

[0052] 4) Rinse the above complex with deionized water, and dry it in an oven at 60°C. Dry Co(OH) 2 / NF tablets (6 pieces) and 450mg sodium hypophosphite were put into two adjacent porcelain boats respectively (the porcelain boats were p...

Embodiment 3

[0057] The preparation method of the integrated CoP nanosheet array as a monolithic peroxidase comprises the following steps:

[0058] 1) Cut the commercial nickel foam into a square of 1cm×1cm, soak it with 37% hydrochloric acid for 30 minutes and ultrasonically clean it with deionized water for 10 minutes, then move it to a 60°C constant temperature drying oven to dry to obtain pure foam nickel;

[0059] 2) Dissolve 1.4055g of cobalt sulfate and 1.9g of urea into 100mL of deionized water, and mix well by stirring at room temperature for 20min;

[0060] 3) Put the treated foamed nickel (30 pieces) and the above solution in a hydrothermal reaction kettle for 48 hours at 120°C to obtain Co(OH) 2 Nanosheet array modified nickel foam composite;

[0061] 4) Rinse the above complex with deionized water, and dry it in an oven at 60°C. Dry Co(OH) 2 / NF tablets (6 pieces) and 600mg sodium hypophosphite were put into two adjacent porcelain boats respectively (the porcelain boats wer...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com