Method for recovering copper, zinc, cobalt and nickel from various waste materials containing ferrous metals

A non-ferrous metal and copper recovery technology, applied in the direction of improving process efficiency, can solve the problems of incomplete separation of valuable metals, sulfide pollution of the environment, etc., and achieve the effect of less impurities, high purity, energy and cost saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

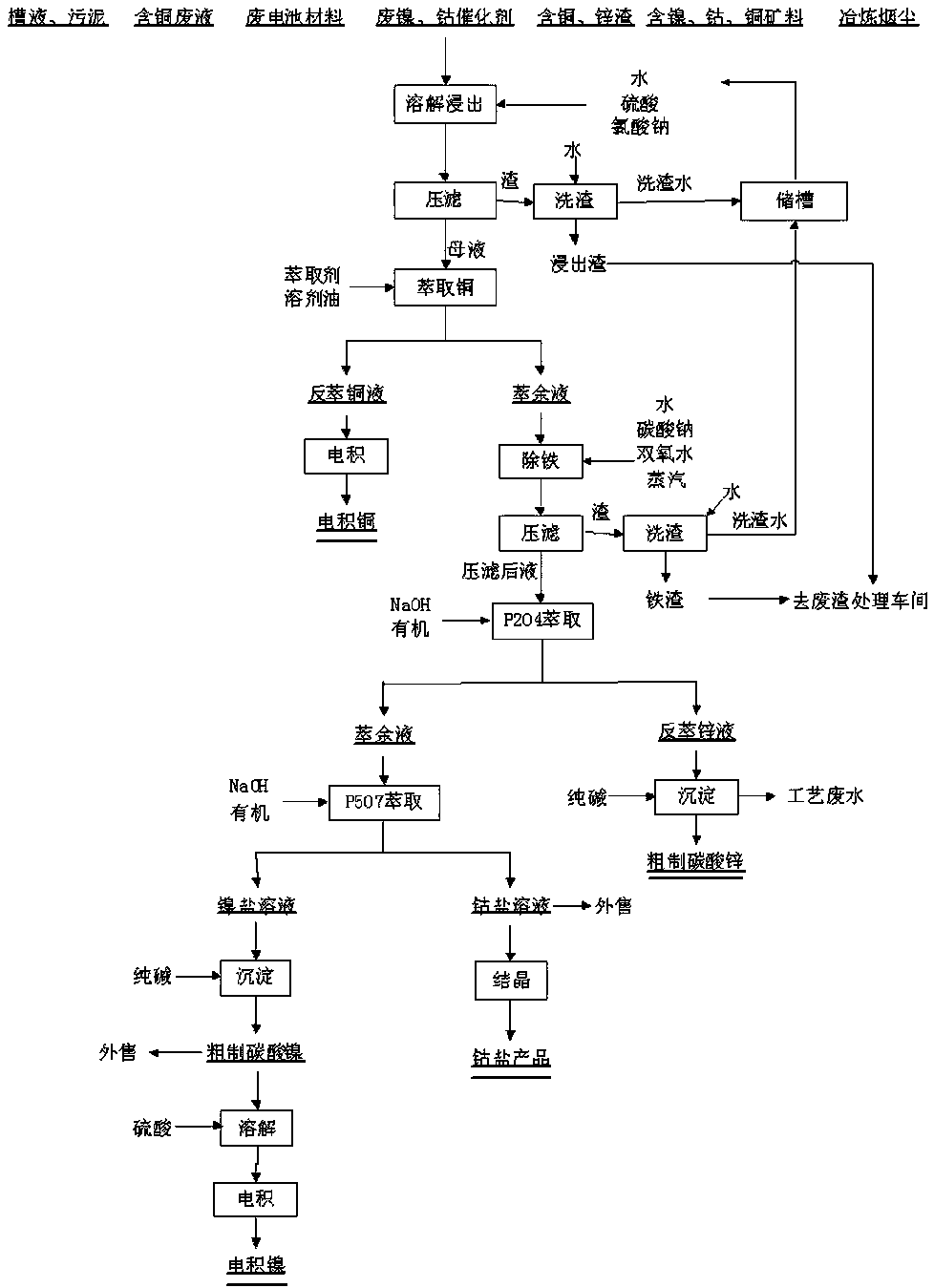

Method used

Image

Examples

Embodiment 1

[0062] (1) Dissolving and leaching:

[0063] Mix 500kg of various waste materials containing non-ferrous metals, and measure the mass content of each metal, copper 2.10%, cobalt 0.56%, zinc 3.12%, iron 16.33%, nickel 1.88%. Grind the waste with a ball mill, the fineness should be below 200 mesh, then add it into 250kg of 30% sulfuric acid, add 5kg of sodium chlorate, stir at 40rpm, raise the temperature to 50°C for the first time, and react for leaching for 1 to 3 hours, then, Start to add 250kg of washing water from steps (2) and (4) dropwise, a large amount of heat will be generated, and the temperature should be controlled at 60°C. When the temperature is too high, use cooling water to cool down. The time for adding the washing water dropwise is 1-2 hours. After adding the washing water, stir for 2-3 hours, so that the soluble non-ferrous metals can be fully dissolved and leached.

[0064] (2), filter press:

[0065] Cool the dissolved leachate to below 50°C, press filter...

Embodiment 2

[0077] (1), Dissolving and leaching:

[0078] Mix 500kg of various waste materials containing non-ferrous metals, and measure the mass content of each metal, copper 2.10%, cobalt 0.56%, zinc 3.12%, iron 16.33%, nickel 1.88%. Grind the waste with a ball mill, the fineness should be below 200 mesh, then add it into 1000kg of 30% sulfuric acid, add 5kg of sodium chlorate, stir at 100rpm, raise the temperature to 50°C for the first time, and react for leaching for 1 to 3 hours, then, Start to add 2500kg of water in steps (2) and (4) dropwise, a large amount of heat will be generated, and the temperature should be controlled at 90°C. When the temperature is too high, use cooling water to cool down. The time for adding the washing water dropwise is 1-2 hours. After adding the washing water, stir for 2-3 hours so that the soluble non-ferrous metals can be fully dissolved and leached.

[0079] (2), filter press:

[0080] Cool the dissolved leachate to below 50°C, press filter, wash ...

Embodiment 3

[0092] (1), Dissolving and leaching:

[0093] Mix 500kg of various waste materials containing non-ferrous metals, and measure the mass content of each metal, copper 2.10%, cobalt 0.56%, zinc 3.12%, iron 16.33%, nickel 1.88%. Grind the waste with a ball mill, the fineness is required to be below 200 mesh, then add it to 500kg of 30% sulfuric acid, add 5kg of sodium chlorate, stir at 60rpm, raise the temperature to 50°C for the first time, and react for leaching for 1 to 3 hours, then, Start to add 1000kg of washing water from steps (2) and (4) dropwise, a large amount of heat will be generated, and the temperature should be controlled at 80°C. When the temperature is too high, use cooling water to cool down. The time for adding the washing water dropwise is 1-2 hours. After adding the washing water, stir for 2-3 hours so that the soluble non-ferrous metals can be fully dissolved and leached.

[0094] (2), filter press:

[0095] Cool the dissolved leachate to below 50°C, press...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com