Preparation method of graphene-supported cobalt disulphide oxygen reduction catalyst and application thereof

A cobalt disulfide and graphene technology, applied in electrical components, battery electrodes, circuits, etc., can solve the problems of harsh reaction conditions and complex control processes, and achieve mild and controllable reaction conditions, high catalytic activity, and good synergy. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] This embodiment provides a method for preparing a graphene-supported cobalt disulfide oxygen reduction catalyst, the method is carried out according to the following steps:

[0033] Measure 3ml of graphene oxide solution in 50ml of deionized water for ultrasonic dispersion for 40min, weigh 2.8g of cobalt sulfate and 2.5g of sodium thiosulfate and dissolve them in 15ml of deionized water, add 0.2g of high-purity sulfur powder and stir for 30min, add to Continue to stir in the ultrasonically dispersed graphene oxide solution for 40 minutes, then transfer to a reaction kettle to react at 140°C for 24 hours, and naturally cool to room temperature 20°C. The obtained solid precipitate was centrifuged and washed with ethanol and deionized at a speed of 7000r / min for 5min, and the precipitate obtained by centrifugation was placed in a glass dish and dried at 60°C in a vacuum oven for 8h to obtain a graphene-loaded Cobalt disulfide oxygen reduction catalyst.

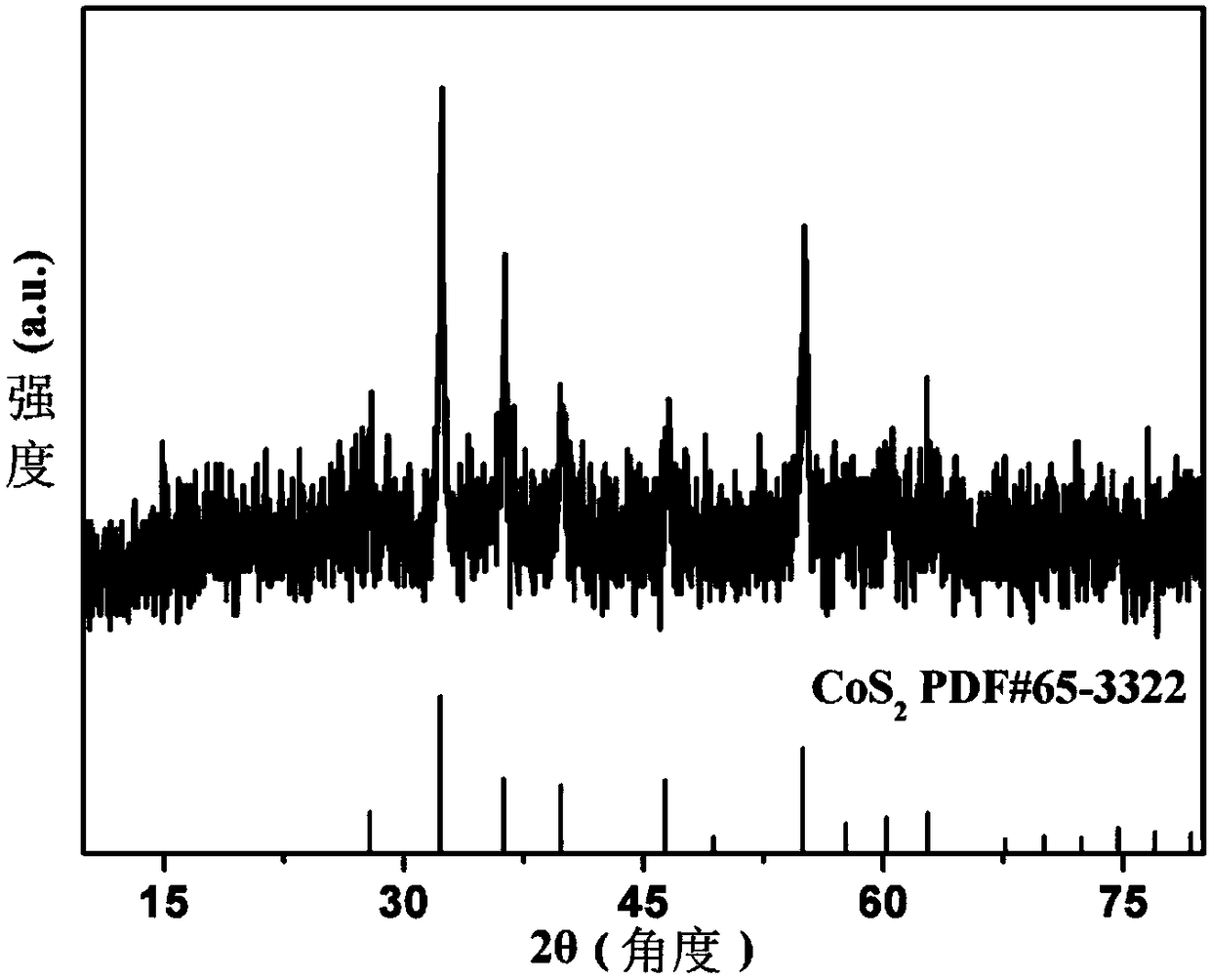

[0034] The XRD sp...

Embodiment 2

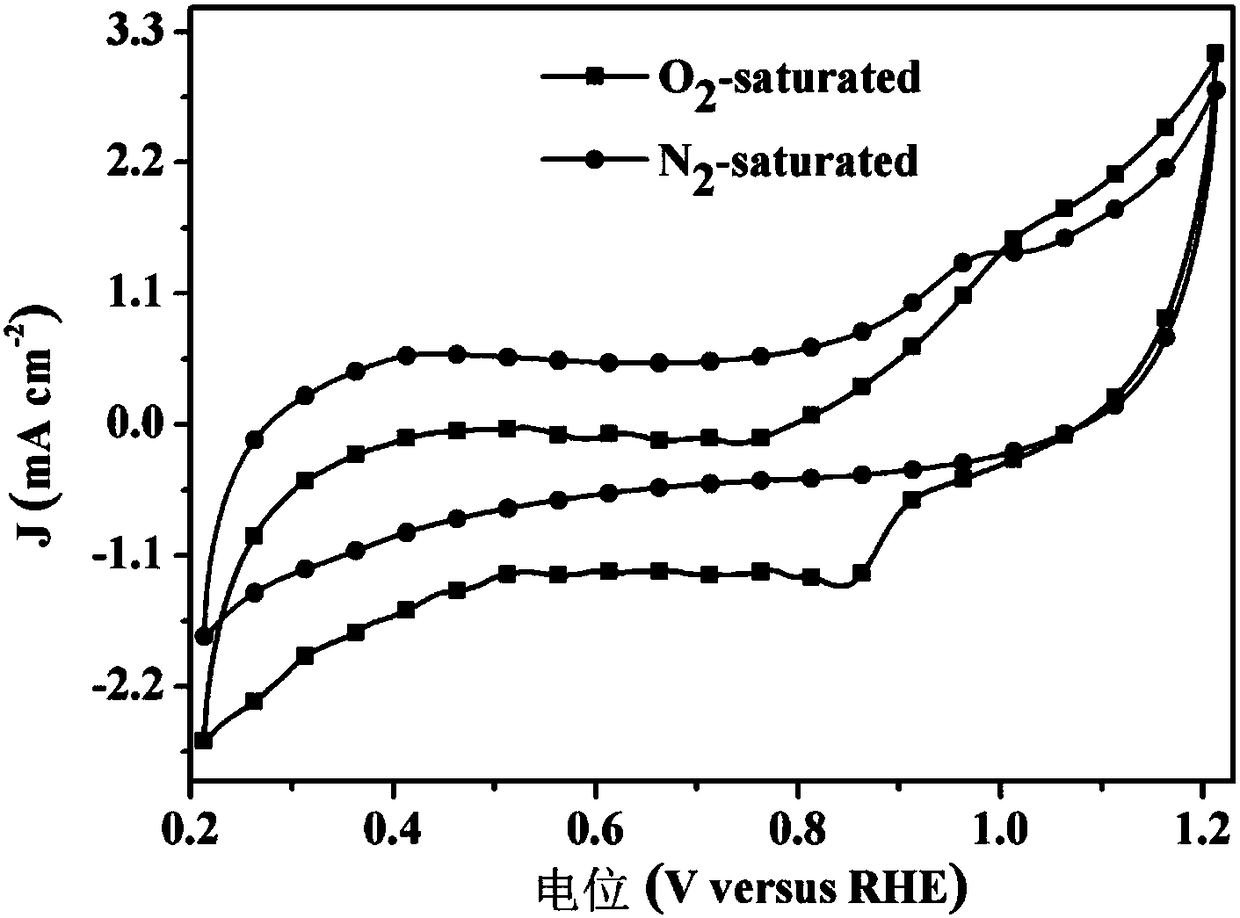

[0038] Measure 5ml of graphene oxide solution in 50ml of deionized water for ultrasonic dispersion for 40min, weigh 2.8g of cobalt sulfate and 2.5g of sodium thiosulfate and dissolve them in 15ml of deionized water, add 0.3g of high-purity sulfur powder and stir for 30min, add to Continue stirring in the ultrasonically dispersed graphene oxide solution for 40 minutes, then transfer to a reaction kettle to react at 140°C for 24 hours, and naturally cool to room temperature 20°C. Centrifuge and wash the obtained solid precipitate with ethanol and deionized water at a speed of 7000r / min for 5 minutes, place the precipitate obtained by centrifugation in a glass dish and dry it in a vacuum oven at 60°C for 8 hours to obtain graphene Supported cobalt disulfide oxygen reduction catalyst. The application of the graphene-supported cobalt disulfide oxygen reduction catalyst prepared by the preparation method of the graphene-supported cobalt disulfide oxygen reduction catalyst is applied...

Embodiment 3

[0040] Measure 5ml of graphene oxide solution in 50ml of deionized water for ultrasonic dispersion for 40min, weigh 2.8g of cobalt sulfate and 4.9g of sodium thiosulfate and dissolve them in 15ml of deionized water, add 0.2g of high-purity sulfur powder and stir for 30min, add to Continue stirring in the ultrasonically dispersed graphene oxide solution for 40 minutes, then transfer to a reaction kettle to react at 140°C for 24 hours, and naturally cool to room temperature 20°C. Centrifuge and wash the obtained solid precipitate with ethanol and deionized water at a speed of 7000r / min for 5 minutes, place the precipitate obtained by centrifugation in a glass dish and dry it in a vacuum oven at 60°C for 8 hours to obtain graphene Supported cobalt disulfide oxygen reduction catalyst. The application of the graphene-supported cobalt disulfide oxygen reduction catalyst prepared by the preparation method of the graphene-supported cobalt disulfide oxygen reduction catalyst is applied...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com