Rare-earth-cerium-chromium-cobalt electroplating solution and electroplating method thereof

A rare earth cerium and cobalt electroplating technology, applied in the field of electroplating, can solve the problems of low plating solution coverage and poor corrosion resistance of the coating, and achieve the effects of strong coverage and good corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

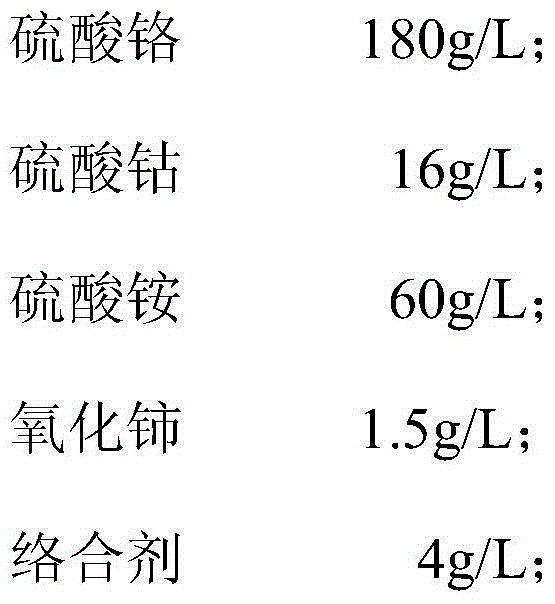

[0019] Embodiment 1: The pH value of the rare earth cerium-chromium-cobalt electroplating solution of the present embodiment is 2.5, and comprises the following components:

[0020]

[0021]

[0022] Use this rare earth cerium-chromium-cobalt plating solution electroplating method as follows:

[0023] Put the carbon electrode into the rare earth cerium-chromium-cobalt electroplating solution as the anode, put the workpiece into the rare earth cerium-chromium-cobalt electroplating solution as the cathode, connect the DC power supply, and set the temperature at the temperature of the rare earth cerium-chromium-cobalt electroplating solution at 40°C, the cathode current density is 50mA / cm 2 The electroplating was carried out for 4 minutes at a lower temperature to obtain a rare earth cerium-chromium-cobalt coating.

Embodiment 2

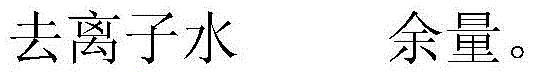

[0024] Embodiment 2: The pH value of the rare earth cerium-chromium-cobalt electroplating solution of the present embodiment is 2.5, and comprises the following components:

[0025]

[0026] Use this rare earth cerium-chromium-cobalt plating solution electroplating method as follows:

[0027] Put the carbon electrode into the rare earth cerium-chromium-cobalt electroplating solution as the anode, put the workpiece into the rare earth cerium-chromium-cobalt electroplating solution as the cathode, connect the DC power supply, and set the temperature at the temperature of the rare earth cerium-chromium-cobalt electroplating solution at 45°C, the cathode current density is 80mA / cm 2 The electroplating was carried out for 5 minutes at a lower temperature to obtain a rare earth cerium-chromium-cobalt coating.

Embodiment 3

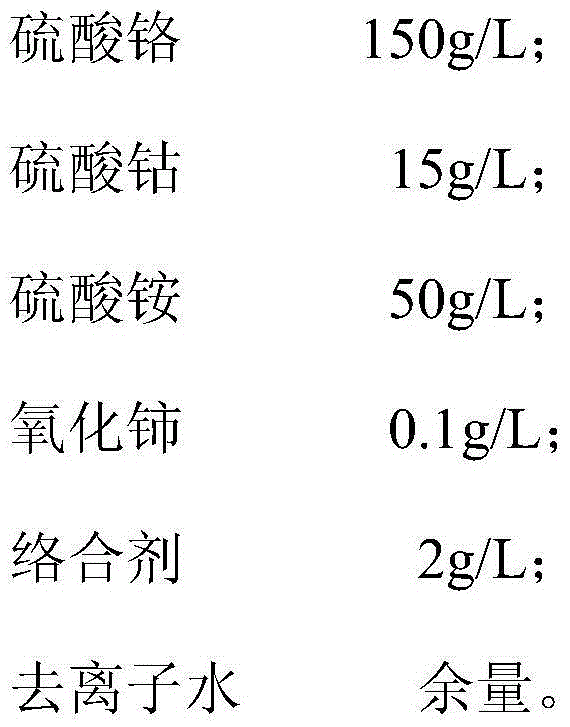

[0028] Embodiment 3: the pH value of the rare earth cerium-chromium-cobalt electroplating solution of the present embodiment is 3, comprises the following components:

[0029]

[0030] Use this rare earth cerium-chromium-cobalt plating solution electroplating method as follows:

[0031] Put the carbon electrode into the rare earth cerium-chromium-cobalt electroplating solution as the anode, put the workpiece into the rare earth cerium-chromium-cobalt electroplating solution as the cathode, connect the DC power supply, and set the temperature at the temperature of the rare earth cerium-chromium-cobalt electroplating solution Electroplating was performed at 40°C and the cathode current density was 100mA / cm2 for 4 minutes to obtain a rare earth cerium-chromium-cobalt coating.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com