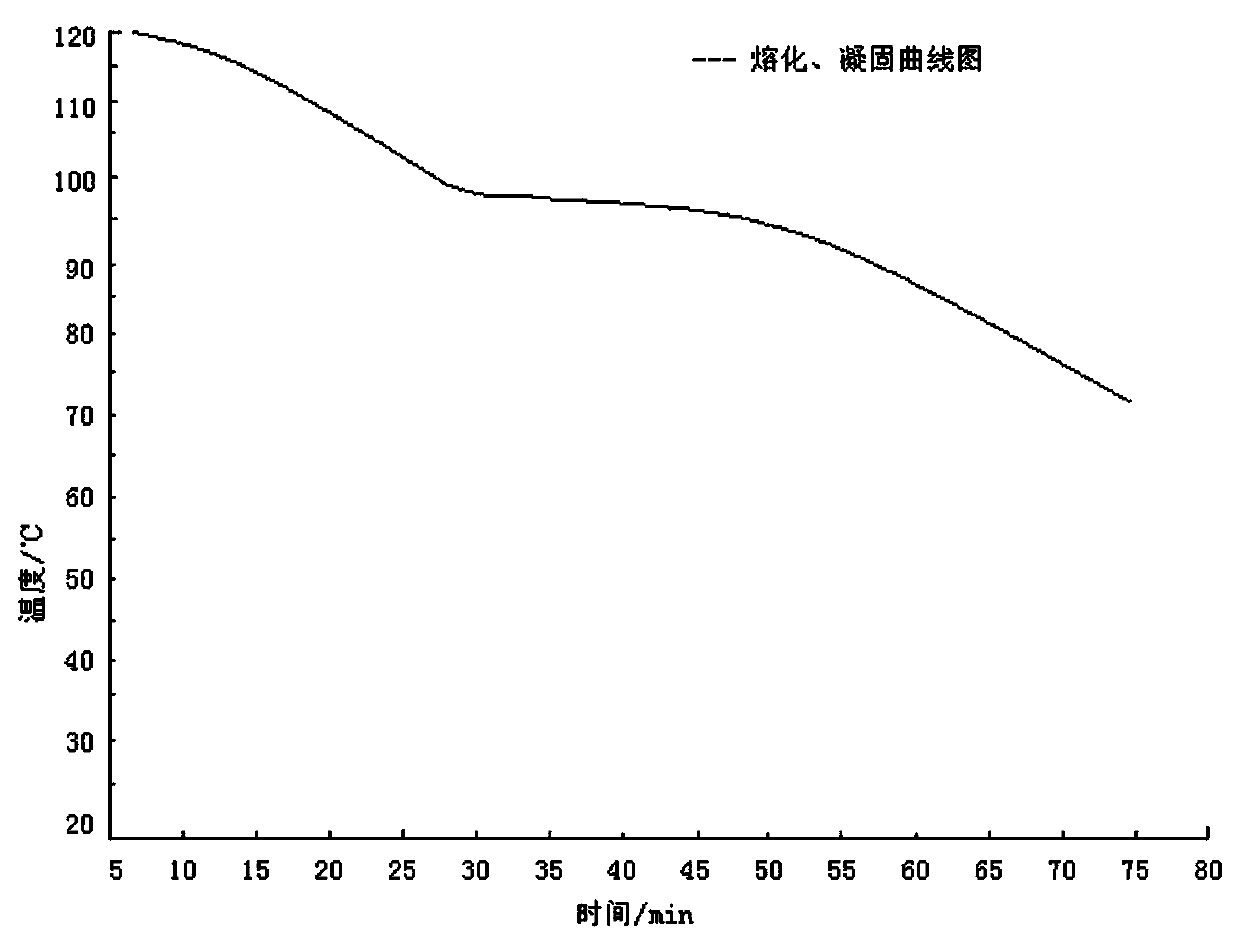

High-temperature inorganic nano phase change energy storage material and preparation method thereof

A phase-change energy storage material and inorganic nanotechnology, applied in the field of low-carbon energy-saving buildings, can solve the problems of phase separation, overcooling of phase-change energy storage materials, etc., and achieve the effects of low cost, easy quality control, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] (1) Take 400g of industrial-grade raw material cobalt sulfate to prepare a saturated aqueous solution, filter to remove impurities, add twice the volume of ethanol to the filtrate, and stir to obtain a nanoscale phase change material, cobalt sulfate CoSO 4 ·7H 2 O core material precipitation;

[0024] (2) Weigh tetraethyl orthosilicate Si(OC 2 h 5 ) 4 171.6g, tetrabutyl orthotitanate Ti(OC 2 h 5 ) 4 Silica gel, titanium oxide, manganese dioxide powder formed by hydrolysis of 280.8g and manganese nitrate Mn(NO3) 2147.6g, orthoethyl silicate Si(OC 2 h 5 ) 4 , Tetrabutyl orthotitanate Ti(OC 2 h 5 ) 4 and manganese nitrate Mn(NO 3 ) 2 Converted into oxides to meet SiO 2 / TiO 2 / MnO 2 The ratio between molecules is 1:1:1;

[0025] (3) Add the weighed items in step (2) to step (1) one by one, and stir while adding, the weight ratio of the total weight of oxides obtained in step (2) to the weight of raw materials in step (1) is 6:4;

[0026] (4) Stir the mixt...

PUM

| Property | Measurement | Unit |

|---|---|---|

| phase transition temperature | aaaaa | aaaaa |

| heat storage density | aaaaa | aaaaa |

| phase transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com