High-voltage agglomerated lithium cobalt oxide material, preparation method and application thereof

A high-voltage lithium cobaltate technology, which is applied in the field of high-voltage agglomerated lithium cobaltate materials and its preparation, can solve problems such as unfavorable industrial mass production, achieve good coating effect, improve high-rate performance, and high-rate performance Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

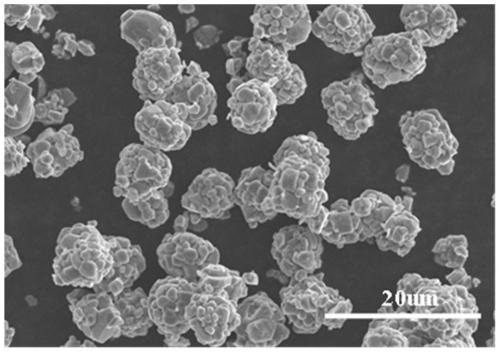

Embodiment 1

[0035] A high-voltage agglomerated lithium cobalt oxide material is prepared through the following steps:

[0036] (1) Take three cobalt tetroxide (particle size D50 is 6.05μm), lithium carbonate, titanium dioxide and magnesium oxide respectively according to lithium-cobalt molar ratio is 1.02, Ti element doping amount is 1000ppm and Mg element doping amount is 1000ppm, put them into high-speed Fully mix in the ball mill to obtain primary mixed material;

[0037] (2) Put the primary mixed material obtained in step (1) in a high-temperature furnace, sinter at 950° C. for 10 h in an air atmosphere, and then pulverize the sintered product to obtain a first-sintered product;

[0038](3) Take the one-fired product obtained in step (2), then add cobalt hydroxide with a mass fraction of 3%, aluminum oxide with a mass fraction of 0.1% and titanium dioxide with a mass fraction of 0.02%, and fully mix with a high-speed mixer After uniformity, they are placed in a high-temperature furna...

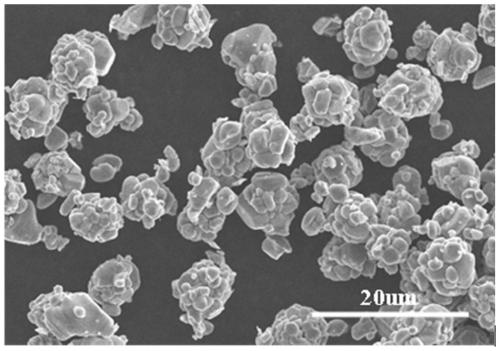

Embodiment 2

[0042] A high-voltage agglomerated lithium cobalt oxide material is prepared through the following steps:

[0043] (1) Weigh cobalt hydroxide (particle size D50 is 6.12μm), lithium hydroxide, aluminum oxide and nickel hydroxide respectively according to the lithium-cobalt molar ratio of 1.03, the Al element doping amount of 1000ppm and the Ni element doping amount of 1000ppm , put them into a high-speed ball mill and mix well to obtain a primary mixed material;

[0044] (2) Put the primary mixed material obtained in step (1) in a high-temperature furnace, sinter at 900° C. for 10 hours in an air atmosphere, and then pulverize the sintered product to obtain a first-sintered product;

[0045] (3) Take the one-fired product obtained in step (2), then add 3% cobalt tetroxide by mass fraction, 0.1% magnesium oxide by mass fraction and 0.02% titanium dioxide by mass fraction, and fully mix evenly with a high-speed mixer They are placed in a high-temperature furnace, sintered at 800...

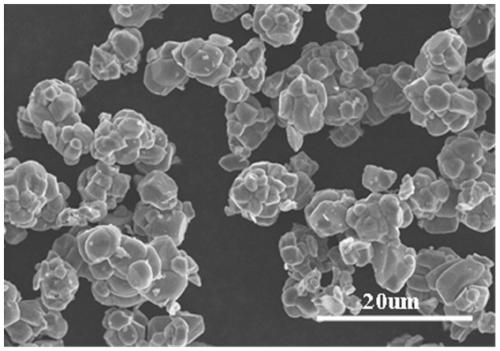

Embodiment 3

[0049] A high-voltage agglomerated lithium cobalt oxide material is prepared through the following steps:

[0050] (1) be 1.03 by lithium-cobalt molar ratio, La element doping amount be 2000ppm and Zr element doping amount be that 1000ppm take cobalt carbonate (particle size D50 is 6.05 μ m), lithium nitrate, lanthanum oxide and zirconium dioxide respectively, will Put them into a high-speed ball mill and mix them well to obtain a primary mixed material;

[0051] (2) Put the primary mixed material obtained in step (1) in a high-temperature furnace, sinter at 1000° C. for 10 hours in an air atmosphere, and then pulverize the sintered product to obtain a primary fired product;

[0052] (3) Take the one-fired product obtained in step (2), then add cobalt sulfate with a mass fraction of 3%, alumina with a mass fraction of 0.05%, and titanium dioxide with a mass fraction of 0.05%, and fully mix evenly with a high-speed mixer They are then placed in a high-temperature furnace, sint...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Compaction density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com