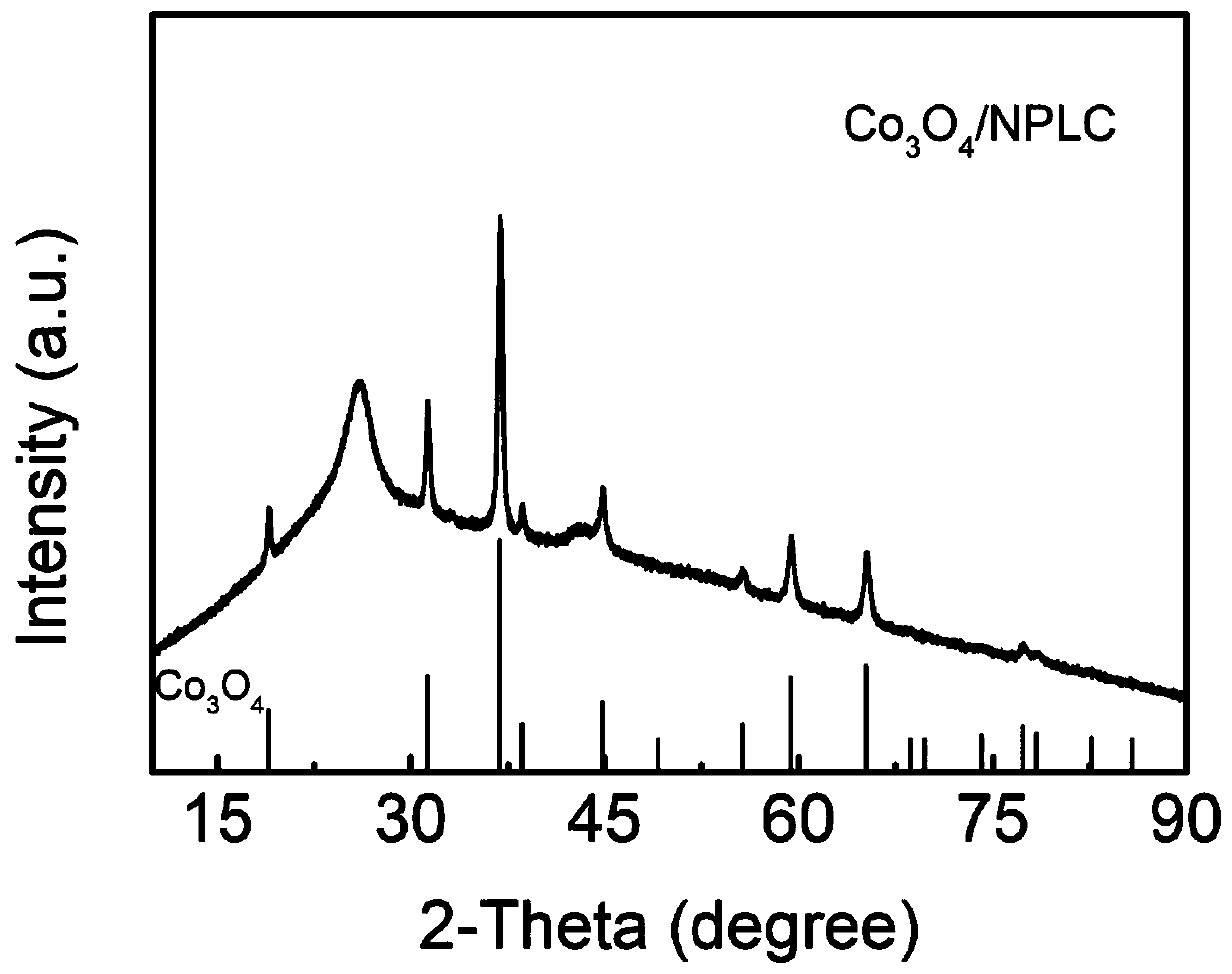

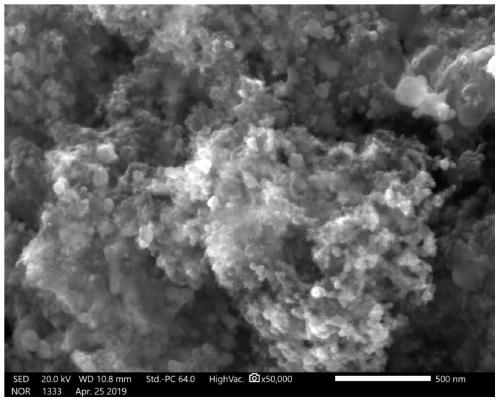

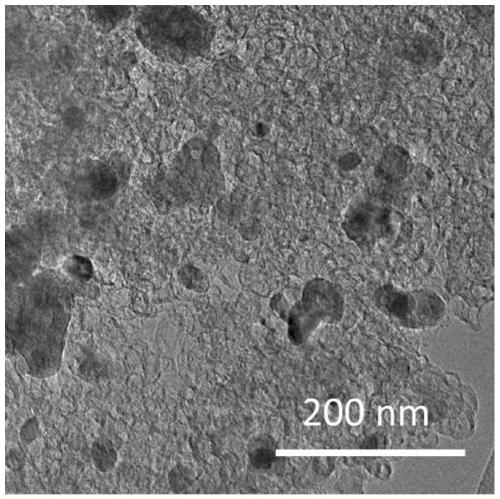

Two-step preparation method of nitrogen-doped carbon-loaded cobaltosic oxide particle catalyst

A technology of tricobalt tetroxide particles and nitrogen-doped carbon, which is applied to electrical components, battery electrodes, circuits, etc., can solve the problems of reducing the number of active components and reducing them, and achieve the effects of promoting contact, saving processing costs, and improving reaction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0037] A two-step method for preparing a nitrogen-doped carbon-supported cobalt tetroxide particle catalyst, comprising the following steps:

[0038] Including the following preparation steps:

[0039] (1) Add the cobalt source and the nitrogen source into deionized water, add the carbon source after being completely dissolved, and disperse evenly by ultrasonic; the mass ratio of the nitrogen source and the carbon source is 1:0.5~2; the cobalt source and the nitrogen source The mass ratio is 0.75~1.5:6~9; the carbon source is one or more of glucose, starch and cellulose acetate; the volume of the deionized water is 38~42mL; the cobalt source is cobalt sulfate, One or more of cobalt chloride, cobalt acetate and cobalt nitrate; the nitrogen source is one or more of urea, dicyandiamide and melamine.

[0040](2) Add the solution configured in step (1) into a 50mL hydrothermal kettle, and react at 170-190°C for 6-10 hours; (3) Suction filter the product obtained in step (2) at roo...

Embodiment 1

[0043]

Embodiment 2

[0045]

[0046]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com