Solid electrolyte and preparation method thereof

A solid electrolyte and powder technology, applied in the field of electrolytes, can solve problems such as poor thermal shock resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0046] The present invention also provides a method for preparing a solid electrolyte, which is used to prepare the solid electrolyte. The preparation method includes:

[0047] S1. 80wt%-98wt% of ZrO 2 Mix with 2wt%-5wt% stabilizer to obtain powder;

[0048] S2. Superfine the obtained powder;

[0049] S3. Mix the powder after superfine treatment with the binder according to the mass ratio of 20-50:50-80, the mass percentage of the binder includes: 80%-95% paraffin , 1%-7% of the first additive and 0.1%-0.8% of the second additive;

[0050] S4. mixing the mixture obtained after mixing;

[0051] S5. After kneading, granulation, injection, degreasing and sintering are carried out to obtain a solid electrolyte.

[0052] As an optional embodiment, the first step of aging treatment is performed on the prepared solid electrolyte at 1100°C-1350°C for 1-3 hours; the second step is performed on the prepared solid electrolyte at 1000°C-1400°C Aging treatment 6-12 hours.

[0053] As...

Embodiment 1

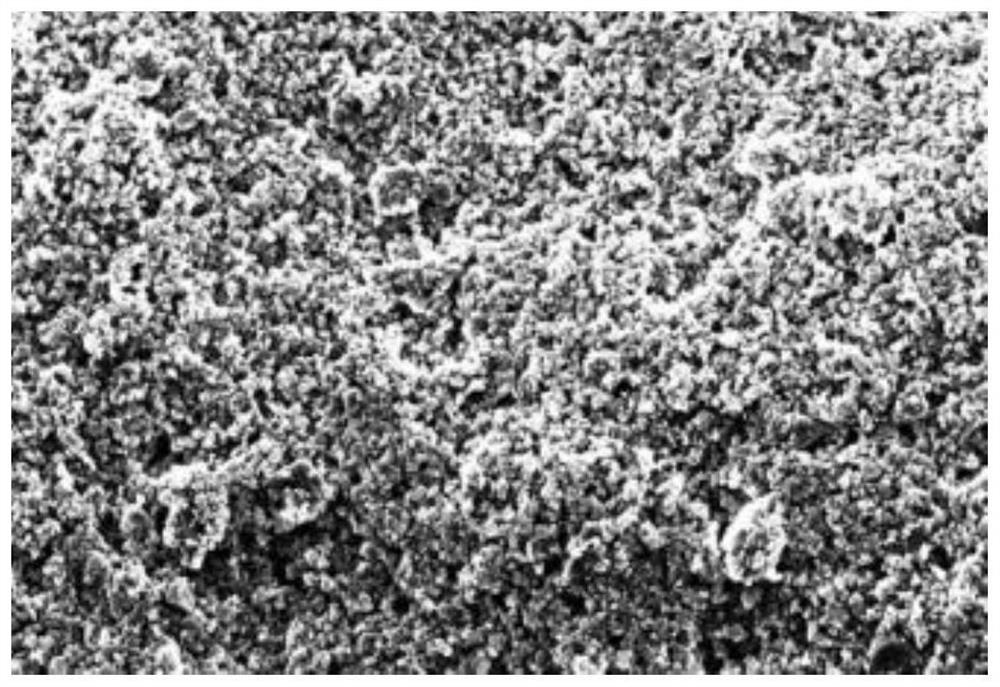

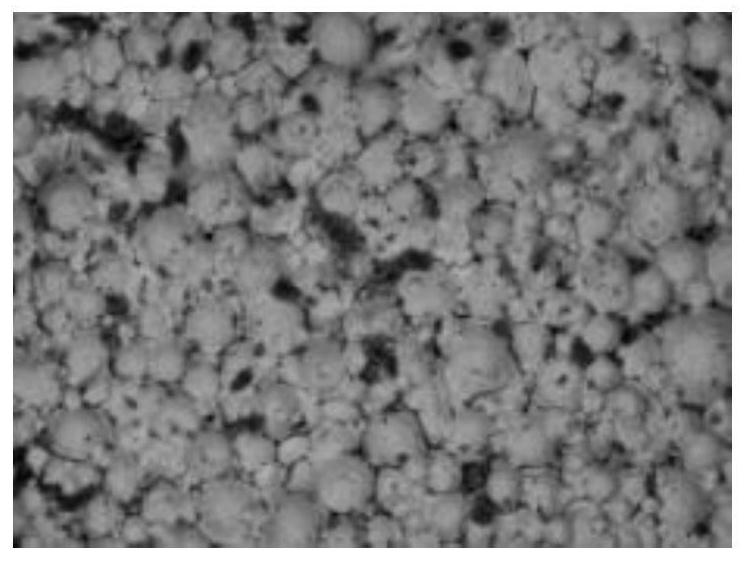

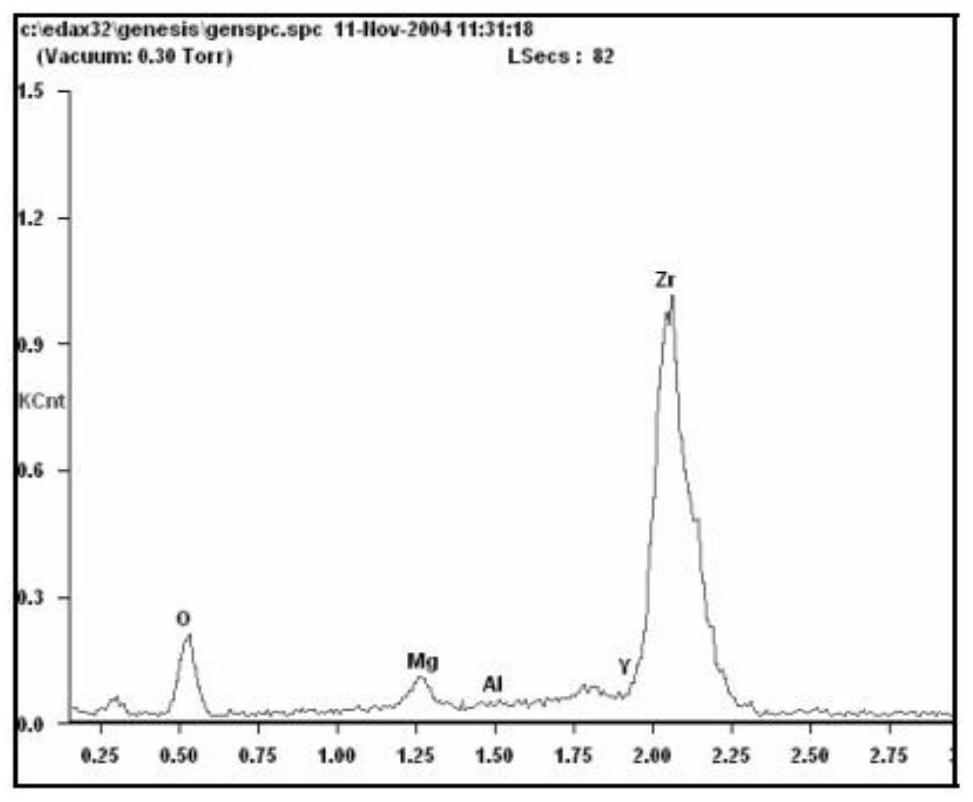

[0056] This embodiment provides a solid electrolyte, wherein the powder mass percentage is: 95% ZrO 2 , 2% CaO, 2% MgO and 1% CeO 2 The mass percentage of the adhesive is: 86.4% of PW, 5% of EVA, 4% of PP, 4% of HDPE, 0.4% of beeswax and 0.2% of SA; the mass percentage of adhesive and powder is: 3: 7. First, the powder is subjected to ultra-grinding treatment, and the electron microscope picture after treatment can be found in figure 1 , and then knead the powder and binder, then granulate, inject, degrease and sinter to prepare the required solid electrolyte. In this implementation, the mixing temperature is preferably 180° C., and the mixing time is preferably 8 hours. The sintering temperature in this embodiment is preferably pre-fired at low temperature to 900° C., and the sintering time is preferably 8 hours, and then the sintering temperature is raised to 1650° C., and the sintering time is 12 hours. After the sintering is completed, aging treatment is performed on t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com