Heat-preservation, heat-insulation, anti-rust and anti-corrosion coating for chassis

A thermal insulation, anti-rust and anti-corrosion technology, applied in the direction of anti-corrosion coatings, polyester coatings, epoxy resin coatings, etc., can solve the problems of expensive chassis care, easy to be corroded, etc., to improve wear resistance, enhance anti-rust and anti-corrosion Performance, enhanced surface activity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

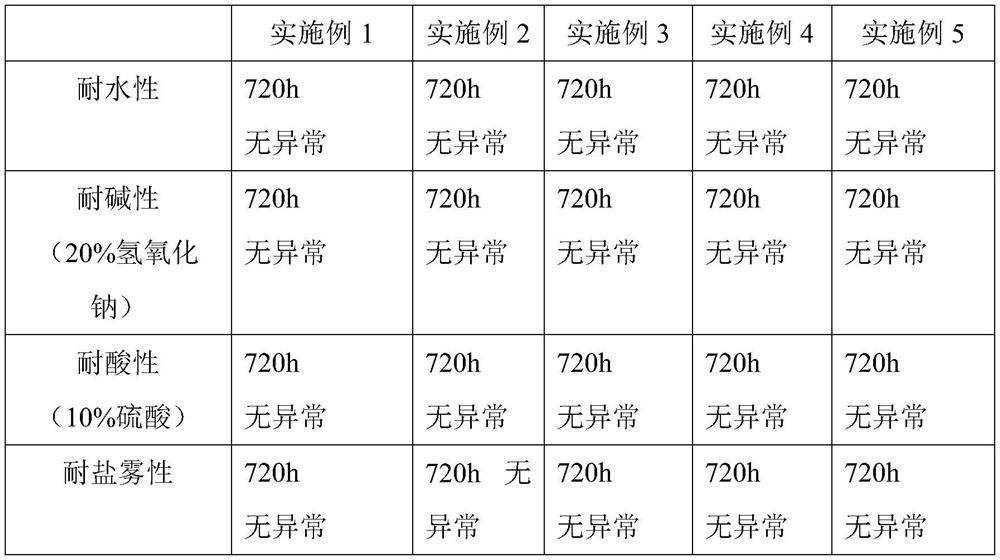

Examples

Embodiment 1

[0019] The preparation process of the heat-insulating, heat-insulating, rust-proof and anti-corrosion paint for vehicle chassis of the present embodiment is:

[0020] Step 1. Add 3 parts of nano-silicon dioxide, 1 part of sodium dodecyl benzene sulfonate, 13 parts of deionized water and stir and disperse evenly under high-speed mechanical stirring; the rotating speed of described high-speed mechanical stirring is: 1800 ~2000rpm; the mass ratio of the nano-silicon dioxide and the dispersant is 3:1.

[0021] Step 2: Add 65 parts of acrylic acid-modified alkyd resin and 33 parts of epoxy resin to the uniform material of step 1, heat up the temperature to 50±5°C stably, and stir evenly at a rotating speed of 600-800 rpm .

[0022] Step 3: After the mixture in step 2 is cooled to room temperature, 0.9 parts of composite magnesium aluminum silicate and 1 part of dodecyl ester are added, and the mixture is uniformly mixed at room temperature.

Embodiment 2

[0024] The preparation process of the heat-insulating, heat-insulating, rust-proof and anti-corrosion paint for vehicle chassis of the present embodiment is:

[0025] Step 1. Add 6 parts of nano-silicon dioxide, 2 parts of sodium dodecyl benzene sulfonate, 15 parts of deionized water and stir and disperse evenly under high-speed mechanical stirring; the rotating speed of described high-speed mechanical stirring is: 1800 ~2000rpm; the mass ratio of the nano-silicon dioxide and the dispersant is 3:1.

[0026] Step 2. Add 70 parts of acrylic acid modified alkyd resin and 40 parts of epoxy resin to the uniform material of step 1, and the temperature is stably raised to 50±5℃, and stir evenly at the rotating speed of 600~800rpm .

[0027] Step 3: After the mixture in step 2 is cooled to room temperature, 1 part of composite magnesium aluminum silicate and 2 parts of dodecyl ester are added, and the mixture is uniformly mixed at room temperature.

Embodiment 3

[0029] The preparation process of the heat-insulating, heat-insulating, rust-proof and anti-corrosion paint for vehicle chassis of the present embodiment is:

[0030] Step 1. Add 3 parts of nano-silicon dioxide, 1 part of sodium dodecyl benzene sulfonate, 10 parts of deionized water and stir and disperse evenly under high-speed mechanical stirring; the rotating speed of described high-speed mechanical stirring is: 1800 ~2000rpm; the mass ratio of the nano-silicon dioxide and the dispersant is 3:1.

[0031] Step 2. Add 50 parts of acrylic acid modified alkyd resin and 30 parts of epoxy resin to the uniform material of step 1, and the temperature is stably raised to 50±5℃, and stir evenly at the rotating speed of 600~800rpm .

[0032] Step 3: After the mixture in Step 2 is cooled to room temperature, 0.5 part of composite magnesium aluminum silicate and 1 part of dodecyl ester are added, and the mixture is uniformly mixed at room temperature.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com