Patents

Literature

49results about How to "Improve rust and corrosion resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

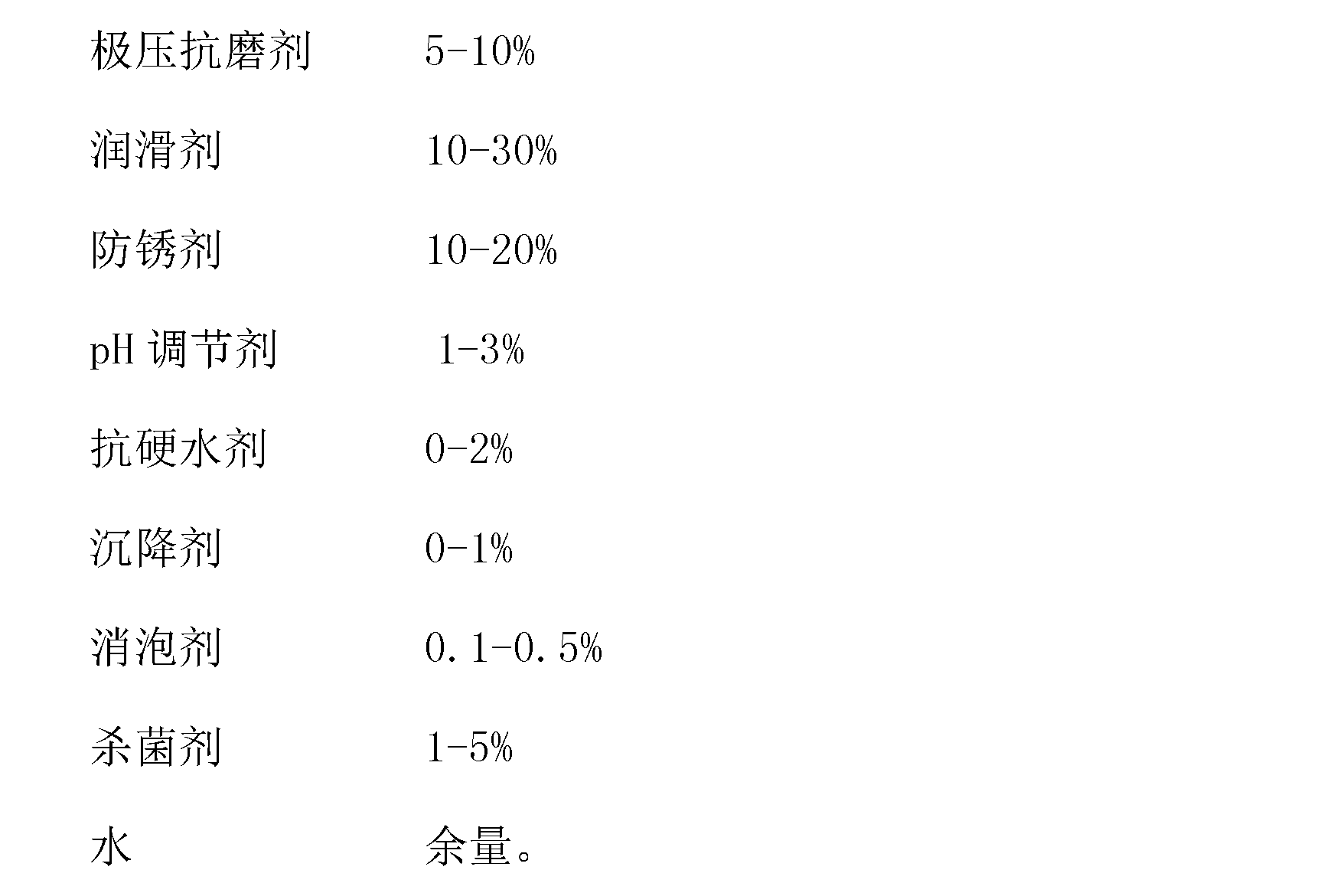

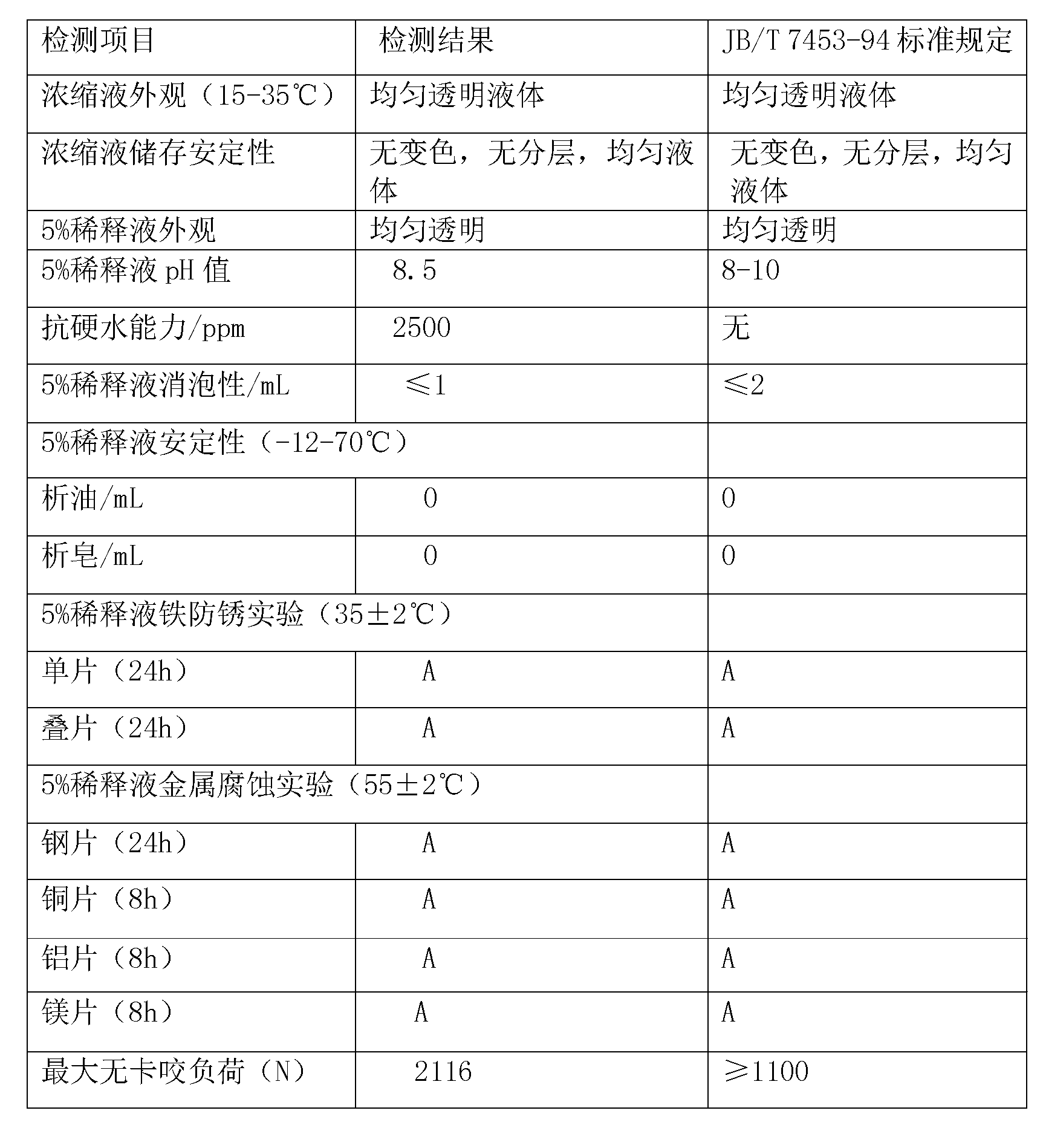

Aluminum-magnesium alloy cutting fluid

ActiveCN102703194AExcellent lubricating and anti-wear propertiesImprove cooling effectLubricant compositionRust converterDefoaming Agents

The invention discloses an aluminum-magnesium alloy cutting fluid which consists of the following components in percentage by weight: 5-10 percent of extreme pressure anti-wear additive, 10-30 percent of lubricating agent, 10-20 percent of anti-rusting agent, 1-3 percent of pH regulator, 0-2 percent of hard water resisting agent, 0-1 percent of settling agent, 0.1-0.5 percent of defoaming agent, 1-5 percent of sterilizing agent and the balance of water. According to the aluminum-magnesium alloy cutting fluid, excellent lubricating and wear resisting performances, cleaning and cooling performance and rust and corrosion resisting performances are obtained, thus cutting bumps can be avoided, a cutter is effectively protected and the processing quality is improved; more heat generated in the processing process is taken away, so that the temperature of the processing surface is reduced and the defects of the curling and the deformation of workpieces caused by high temperature, flammabilityof scrap magnesium at high temperature and the like are effectively overcome; and a processing technique is simplified, and thus the processing period is shortened and the production efficiency is increased.

Owner:上海福岛新材料科技有限公司

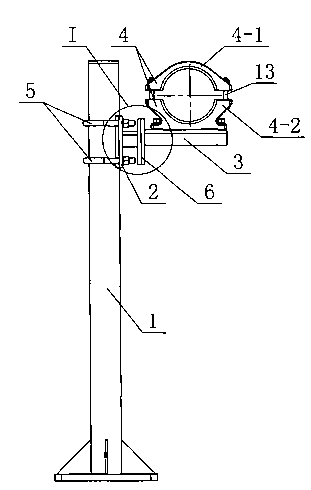

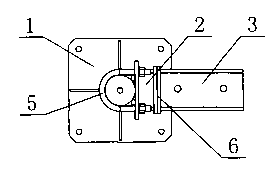

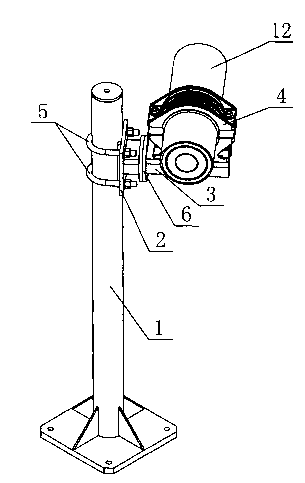

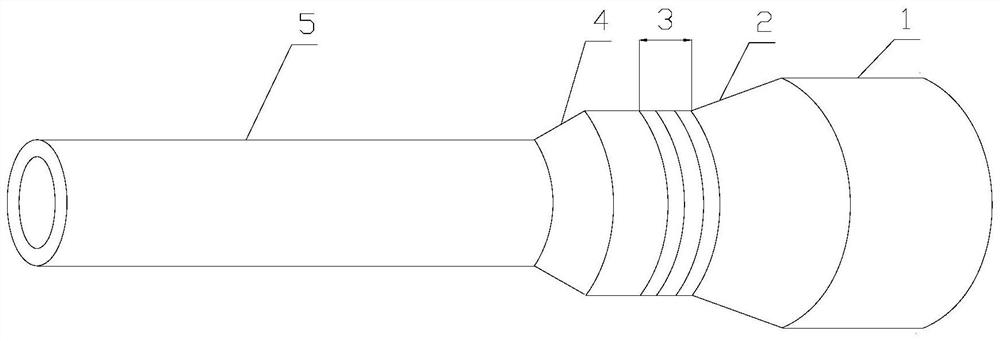

Adjustable type cable fixed support

The invention relates to a cable support, in particular to an adjustable type cable fixed support. The adjustable type cable fixed support comprises a stand column (1), a suspension arm (3), an installation seat C (2) and a U-shaped bolt (5), wherein the installation seat C (2) is fixedly connected with the suspension arm (3), and the installation seat C (2) is connected with the stand column (1) through the U-shaped bolt (5). The adjustable type cable fixed support has the advantages that the installation seat C is connected with the stand column through the U-shaped bolt, the suspension arm which is connected with the installation seat C can move up and down on the stand column, in addition, the suspension arm which is connected with the installation seat C can be horizontally arranged around the stand column in a rotation mode, the stand column and the suspension arm are assembled to form a structure so as to facilitate transportation and machining, a rotating seat is arranged, especially, an installation seat D and an installation seat E form the rotating seat to enable the suspension arm to rotate around the installation seat C, adjusting range is further expanded, use range of a cable support is increased, and the adjustable type cable fixed support is convenient to use.

Owner:江苏安靠智能输电工程科技股份有限公司

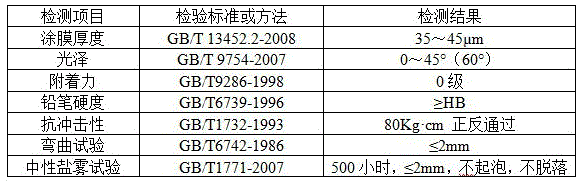

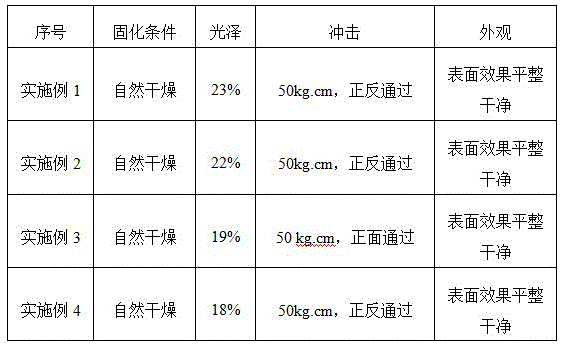

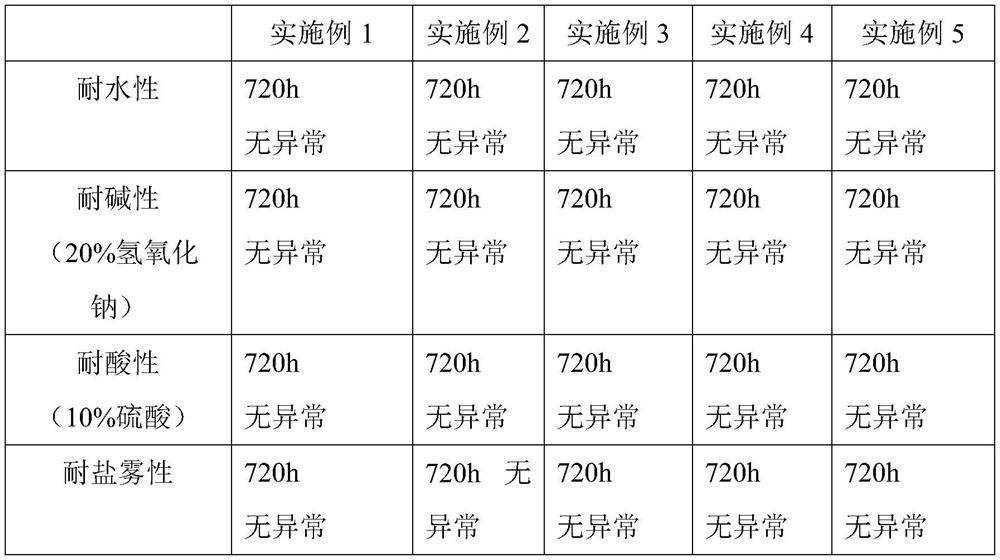

Environment-friendly anticorrosion waterborne primer paint and preparation method thereof

ActiveCN103773175AGood adhesionLow VOC contentAnti-corrosive paintsEpoxy resin coatingsZinc phosphateEmulsion

The invention discloses an environment-friendly anticorrosion waterborne primer paint. The environment-friendly anticorrosion waterborne primer paint comprises the following components in parts by weight: 35-50 parts of waterborne emulsion, 0.5-1 part of waterborne dispersing agent, 0.2-0.5 part of waterborne defoaming agent, 10-35 parts of filler, 1-3 parts of silicon dioxide, 2-3 parts of anti-flash-rust agent, 10-15 parts of zinc phosphate, 1-1.5 parts of organic bentonite, 0.2-0.5 part of pH value regulator, 0.2-0.5 part of thickening agent, 0.5-1 part of film-forming additive, 8-15 parts of pigment and 10-13 parts of water. The invention also discloses a preparation method of the paint. The paint has strong anticorrosion capacity, strong adhesion and high curing speed.

Owner:清远市贝客音涂料有限公司

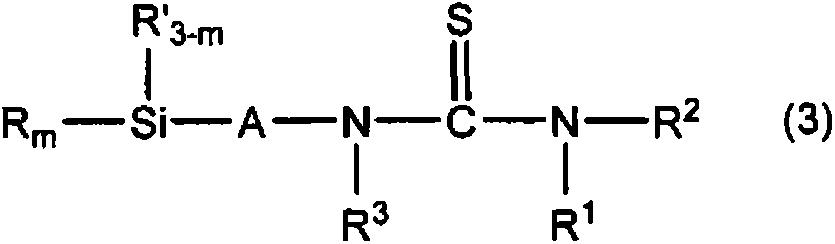

Emission-free reusable waterborne cutting fluid and preparation method thereof

The invention discloses emission-free reusable waterborne cutting fluid. The cutting fluid is characterized by being prepared from the following ingredients in weight percentage: 5 to 15% of high-viscosity water-soluble polyether SDN-20, 0.1 to 10% of graphene, 5 to 25% of polyether SDR-40, 2 to 20% of wetting agent, 0.2 to 1.5% of glacial acetic acid, 0.1 to 10% of complexing agent, 4 to 15% of anti-wear agent, 5 to 15% of triethanolamine, 1 to 2% of Grotan OK and 20 to 77.6% of water. The emission-free reusable waterborne cutting fluid has the advantages of no emission, reusability, no replacement, excellent lubrication cooling performance, anti-wear extreme pressure property, rust and corrosion resistance, high inverse solubility, biological stability, corruptibility resistance, stability in all the items of performance, greenness, environmental friendliness, excellent processability, simple production technology, easily obtained raw materials and good product universality.

Owner:HUBEI CHENGXIANG TECH

Preparation method of iron-silicon soft magnetic alloy powder

The invention provides a preparation method of iron-silicon soft magnetic alloy powder. The preparation method comprises the following steps: (1) preparing alloy through the following raw materials in percentage by weight: 5.0 to 6.2% of Si, 2.0 to 4.0% of Cr, 0.05 to 0.15% of P, and the balance Fe; (2) feeding the raw materials into a crucible, smelting through a vacuum induction furnace, and cooling molten alloy into thin sheets in a rapid solidification manner; (3) crushing the thin sheets; dipping with liquid nitrogen; grinding through a ring hammer; and sieving to obtain fine alloy particle powder; (4) grinding through a low-speed stirring grinding machine, and shaping the powder; (5) thermally processing the powder under a reduction atmosphere, namely, heating to reach the temperature of 780 to 900 DEG C, and maintaining the temperature for 2 to 5 hours; and (6) sieving to obtain fine particular iron-silicon soft magnetic alloy powder meeting the requirement of a user on particle size. With the adoption of the method, the fine iron-silicon soft magnetic alloy powder which has a good appearance and is shaped like spheres can be prepared; the demand of preparing an integrally-formed inductor can be met.

Owner:SOUTH CHINA AGRI UNIV

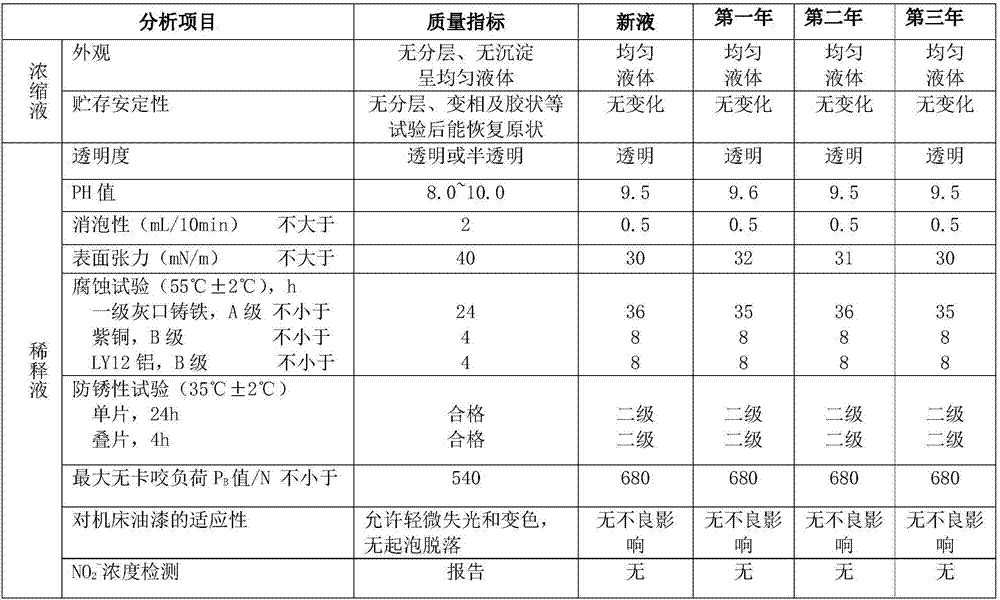

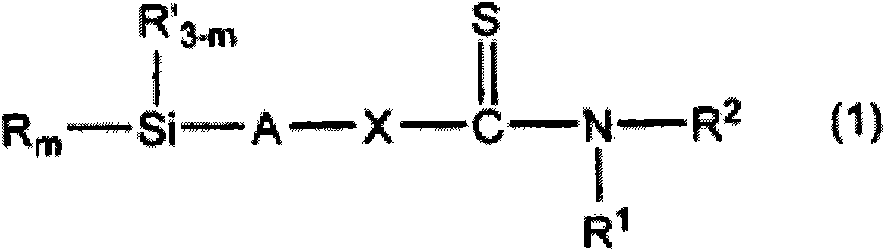

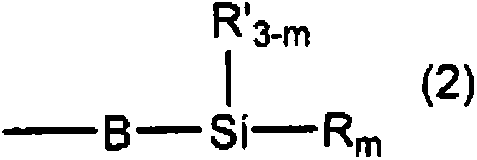

Metal surface treatment agent, surface treated steel and surface treatment method thereof, and coated steel and making method thereof

ActiveCN103572298AStrong anti-rust abilityExcellent processing adhesionMetallic material coating processesOxygen atomOrganosilicon

The present invention relates to a metal surface treatment agent, a surface treated steel and a surface treatment method thereof, and a coated steel and a making method thereof. The chromate-free metal surface treatment agent is most suitable for being used as a metal coated steel, as the pre-processing of the coatings, such as the paint, etc., and can provide the excellent processability, adaptation and corrosion resistance. The metal surface treatment agent takes the organosilicon compounds represented by the general formula (1) as the necessary components, wherein R is hydrolytic perssad, R' is alkyl group having 1-4 carbon atoms, A is a linear chain or branched chain alkylene having 1-8 carbon atoms, X is one of the oxygen atom, the sulphur atom and the nitrogen-atom, R1 and R2 independently and separately represent the hydrogen atom, the alkyl group having 1-20 carbon atoms, the fluoroalkyl having 1-20 carbon atoms, aryl having 6-10 carbon atoms and alkenyl having 2-10 carbon atoms, or the substituent group represented by the general formula (2), m is an integer of 1-3. In the general formula (2), R' is the alkyl group having 1-4 carbon atoms, B is a linear chain or branched chain alkylene having 1-8 carbon atoms, and m is an integer of 1-3.

Owner:SHIN ETSU CHEM IND CO LTD

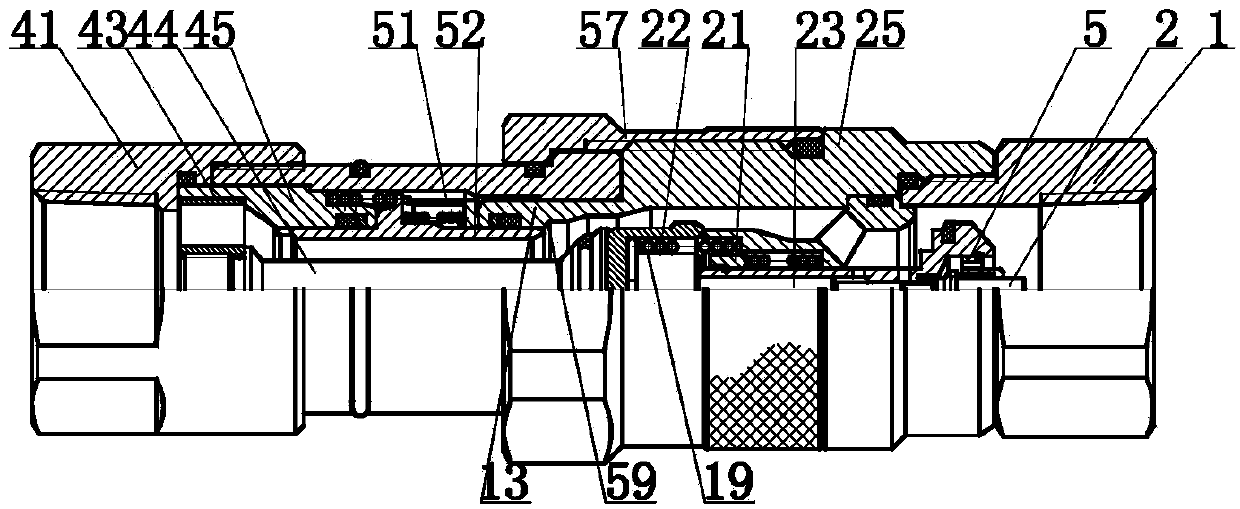

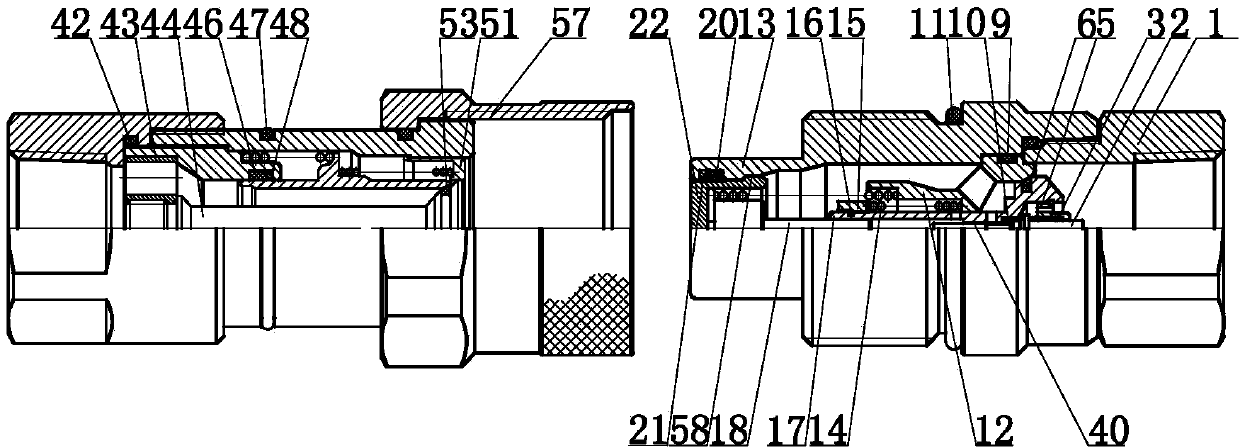

Quick connector working under pressure

ActiveCN103742740ASafe and reliable connectionRealize the demand for pressurized operationCouplingsEnvironmental resistanceWorking temperature

The invention relates to a connecting device fast detached and installed, in particular to a quick connector working under pressure. The quick connector working under pressure comprises a male connector and a female connector. The male connector comprises a plug connector body, a plug valve seat and a plug valve element. The female connector comprises a shell connector body, a shell valve seat and a shell valve element. The outer wall of the right side of the shell connector body is sleeved with an outer cover which is in threaded connection with the plug connector body. The quick connector working under pressure has the advantages that the plug and a socket are connected in a thread locking mode, and a product can be safer and more reliable to connect; an automatic pressure releasing device is arranged, and the requirement for operation under pressure can be met; a plurality of layers of anti-explosion high-temperature-resisting sealing rings and plastic washers are designed in a double sealing mode, and the higher using pressure and a higher using temperature range are ensured; environmentally-friendly chromeplate in a new technology is adopted, the higher rust protection performance and the higher corrosion resisting performance are achieved; the working temperature can reach -40 DEG C to 200 DEG C, and the number of times of plugging and using can reach up to 500,000.

Owner:ZHEJIANG SONGQIAO PNEUMATIC & HYDRAULIC

Preparation method of automobile surface polishing agent

InactiveCN105176409AConvenient sourceSuitable for maintenancePolishing compositionsDistillationDecene

The invention discloses a preparation method of an automobile surface polishing agent, belonging to the field of automobiles. The method comprises the following steps: preparing a chloroplatinic acid-isopropanol catalytic solution, dropwisely adding into alpha-decene to react, and carrying out reduced pressure distillation to obtain methyl long-chain alkylsiloxane; by using carnauba wax and beeswax as raw materials, adding the methyl long-chain alkylsiloxane and triethanolamine in the molten state to obtain a polishing agent semifinished product; and mixing the semifinished product with castor oil and anhydrous ethanol, and adding sodium dodecyl benzene sulfonate and sodium borate to obtain the automobile surface polishing agent. The polishing agent disclosed by the invention can enhance the brightness, has the advantages of rust and corrosion resistance, favorable stability, no toxicity or harm, convenient raw material sources, simple preparation technique and low production cost, is easy for wiping and suitable for daily automobile maintenance, and has industrial production value.

Owner:高大元

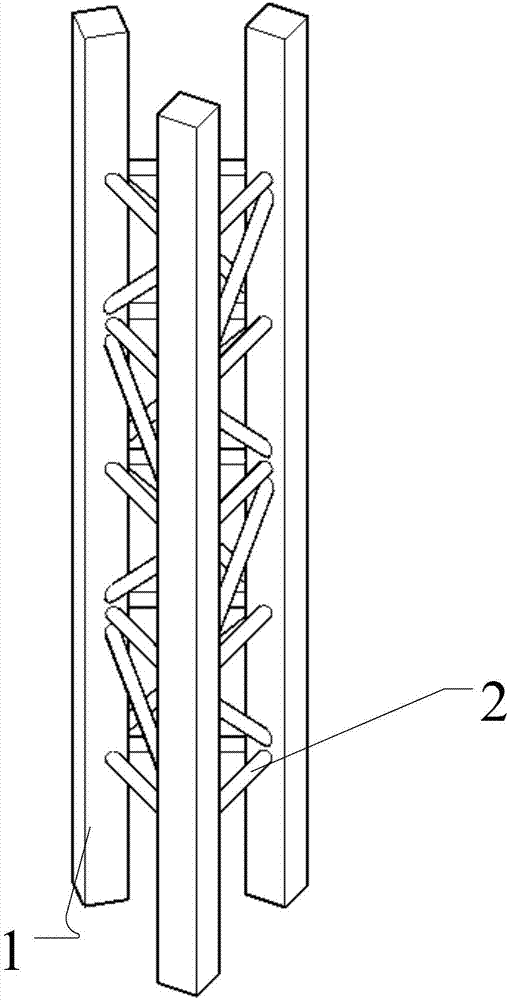

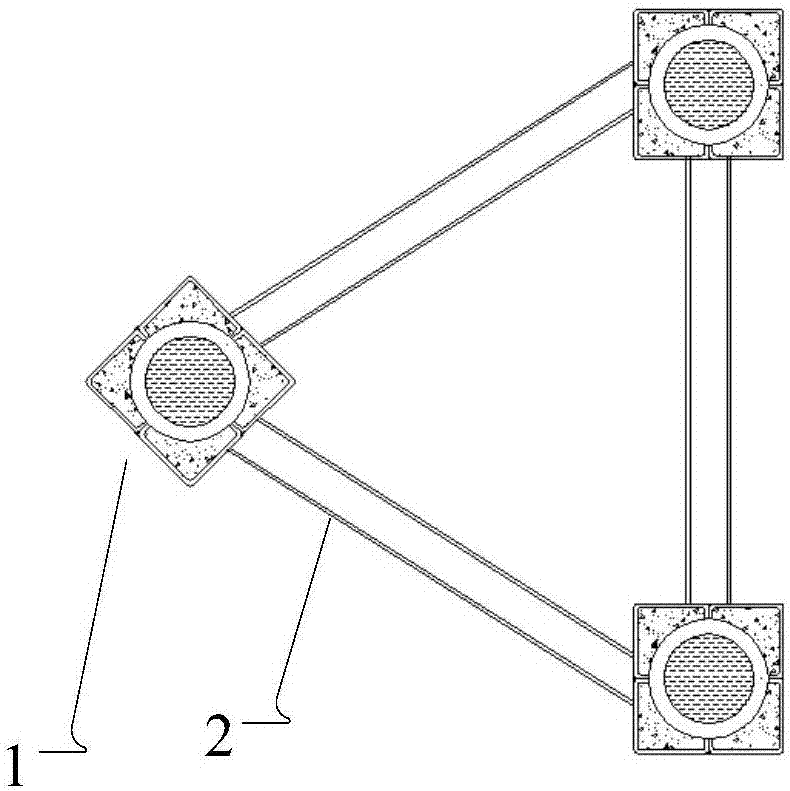

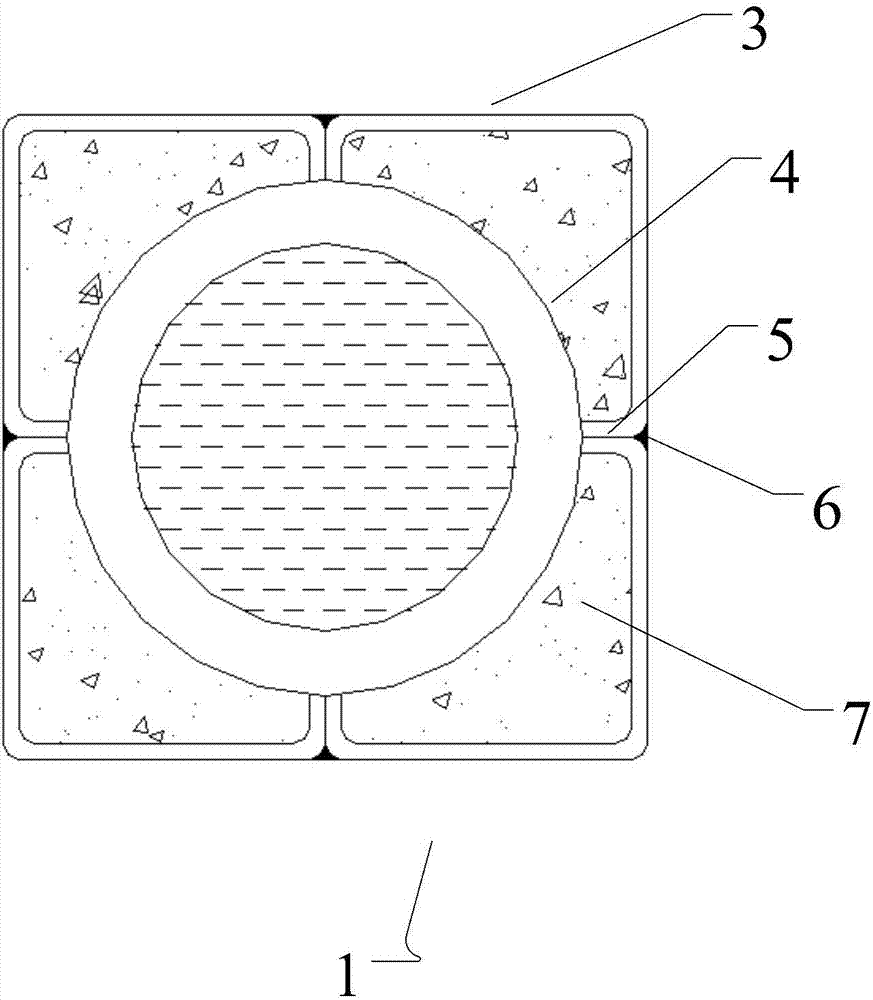

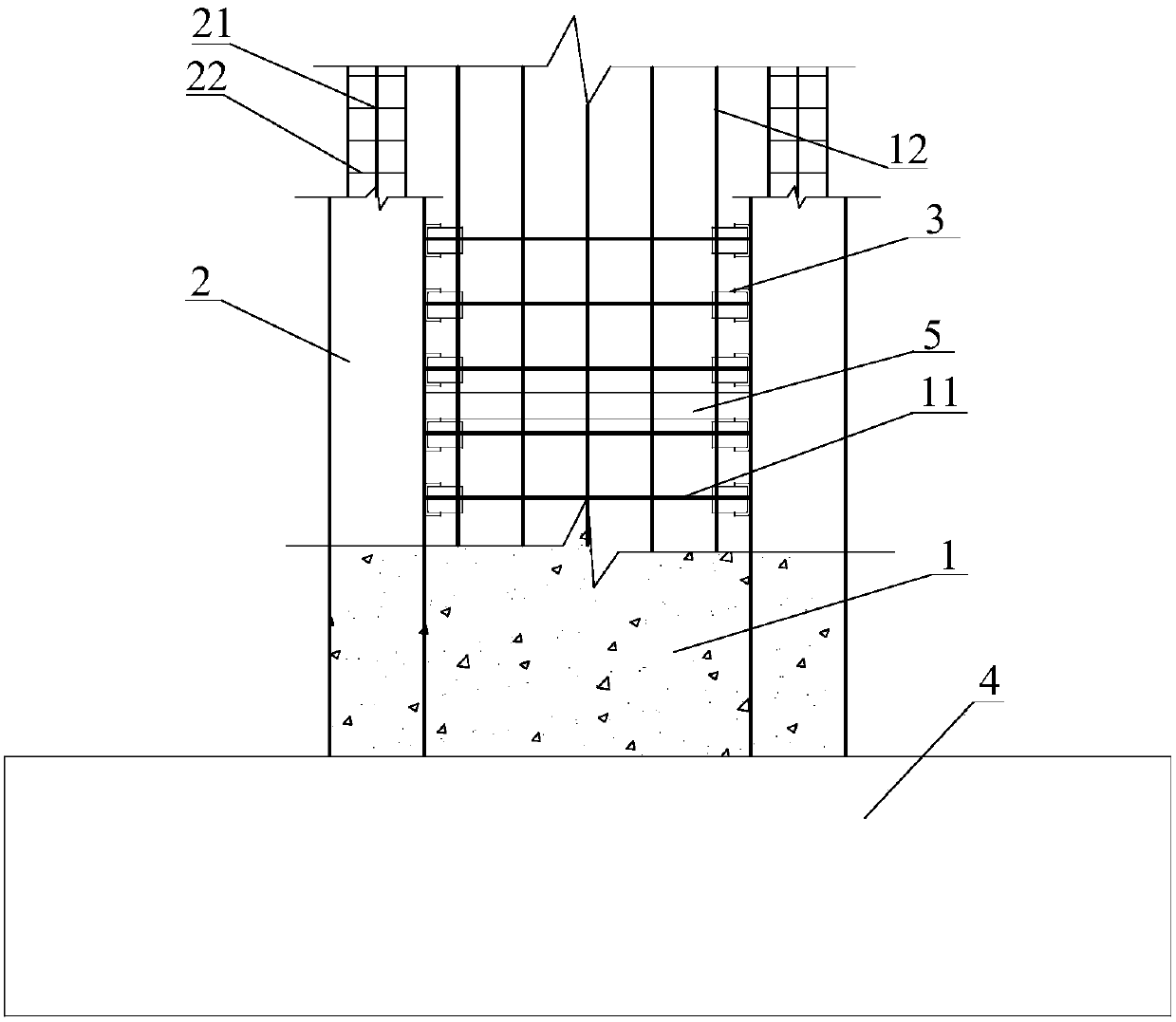

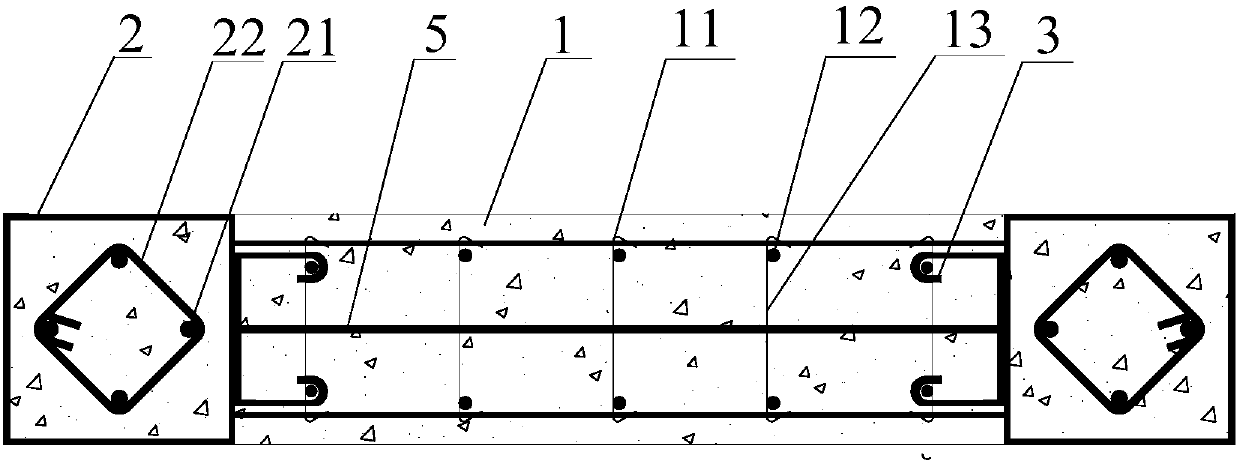

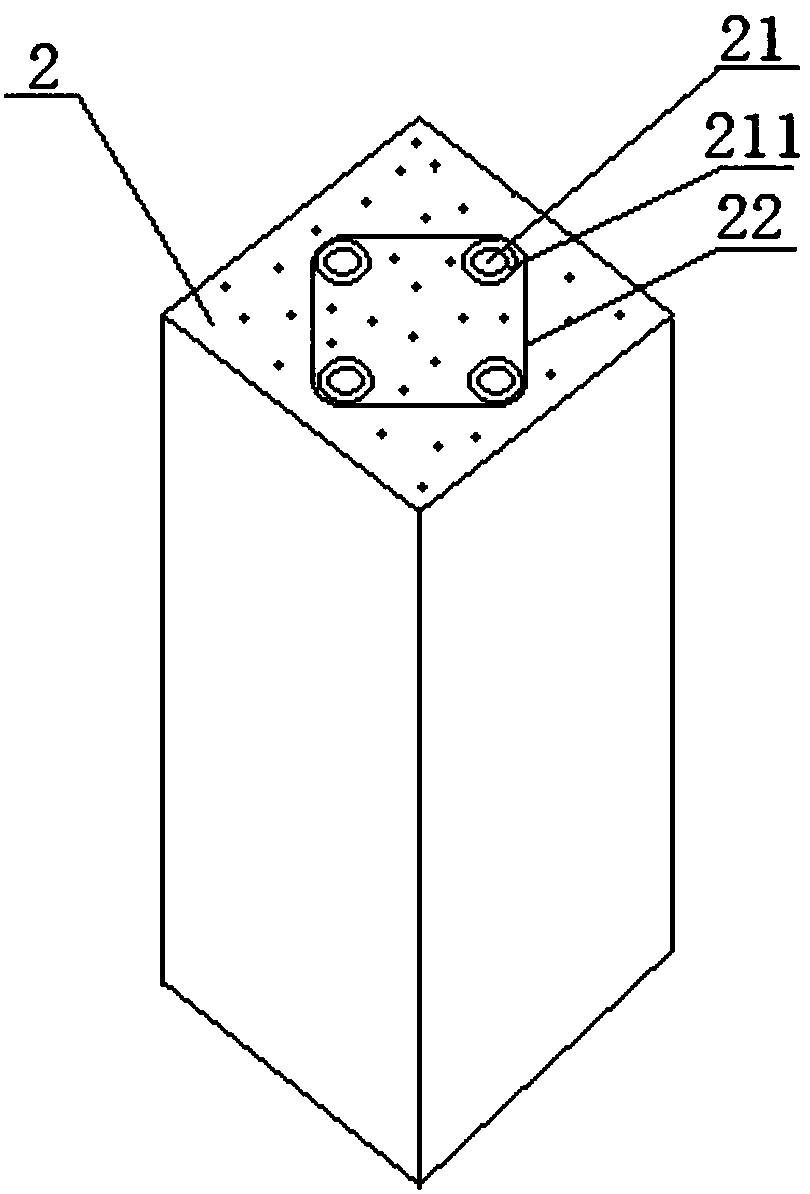

Self-elevating novel latticed pile leg for ocean platform

InactiveCN107165147AIncrease section sizeEasy to installArtificial islandsUnderwater structuresShock resistanceEngineering

The invention discloses a new lattice type pile leg of a self-elevating offshore platform, comprising a pile leg body arranged in parallel with a triangle, and is characterized in that: the pile leg body comprises a square steel pipe, and the inside of the square steel pipe is arranged along the length direction The stiffening rib is welded with a circular steel pipe, the interior of the circular steel pipe is hollow with water, and the space between the square steel pipe and the circular steel pipe is filled with concrete. The novel lattice type pile legs of the self-elevating offshore platform of the invention have the characteristics of high stability, strong bearing capacity, low cost, strong corrosion resistance, excellent seismic resistance, convenient maintenance and long service life.

Owner:HARBIN INST OF TECH SHENZHEN GRADUATE SCHOOL

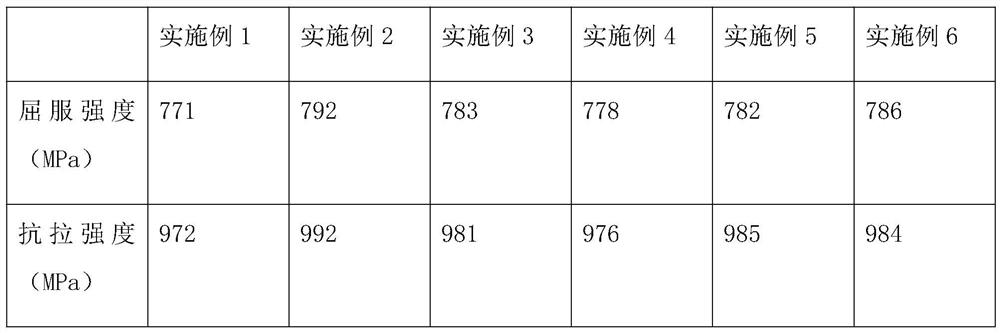

Processing technology of anti-rust anti-corrosion high-strength steel grid bolts

InactiveCN109352277AImprove rust and corrosion resistanceSimple processScrewsLiquid temperatureAcid washing

The invention relates to a processing technology of anti-rust anti-corrosion high-strength steel grid bolts. The processing technology comprises the steps of producing semi-finished products; preserving temperature and performing cooling, wherein the temperature is 730-750 DEG C, and the duration is 6-10h; performing surface treatment, including alkali washing, water washing, acid washing, water washing, phosphorating and cleaning; performing thread forming; performing quenching; performing tempering; performing anti-corrosion pre-treatment, wherein tempered bolts are put into an electrolyte for electrolytic degreasing and then put into a pickling solution for pickling to remove oxide on the surfaces of the bolts, and then sand blasting polishing treatment and alkali corrosion treatment are carried out in sequence; and immersing the bolts after alkali corrosion treatment in anti-corrosion anti-rust oil, and maintaining the liquid temperature at 50 DEG C for immersing for 80min to formanti-rust anti-corrosion layers on the surfaces of the bolts. By improving and adjusting existing technological processes, the processing technology reduces the number of times of heating the bolts, energy consumption and the cost, can improve the strength of the bolts, and is simple in technological process, low in manufacturing cost, good in technological process continuity and high in production efficiency, and the bolts are longer in service life.

Owner:JIANGSU HUAHAI STEEL STRUCTURE CO LTD

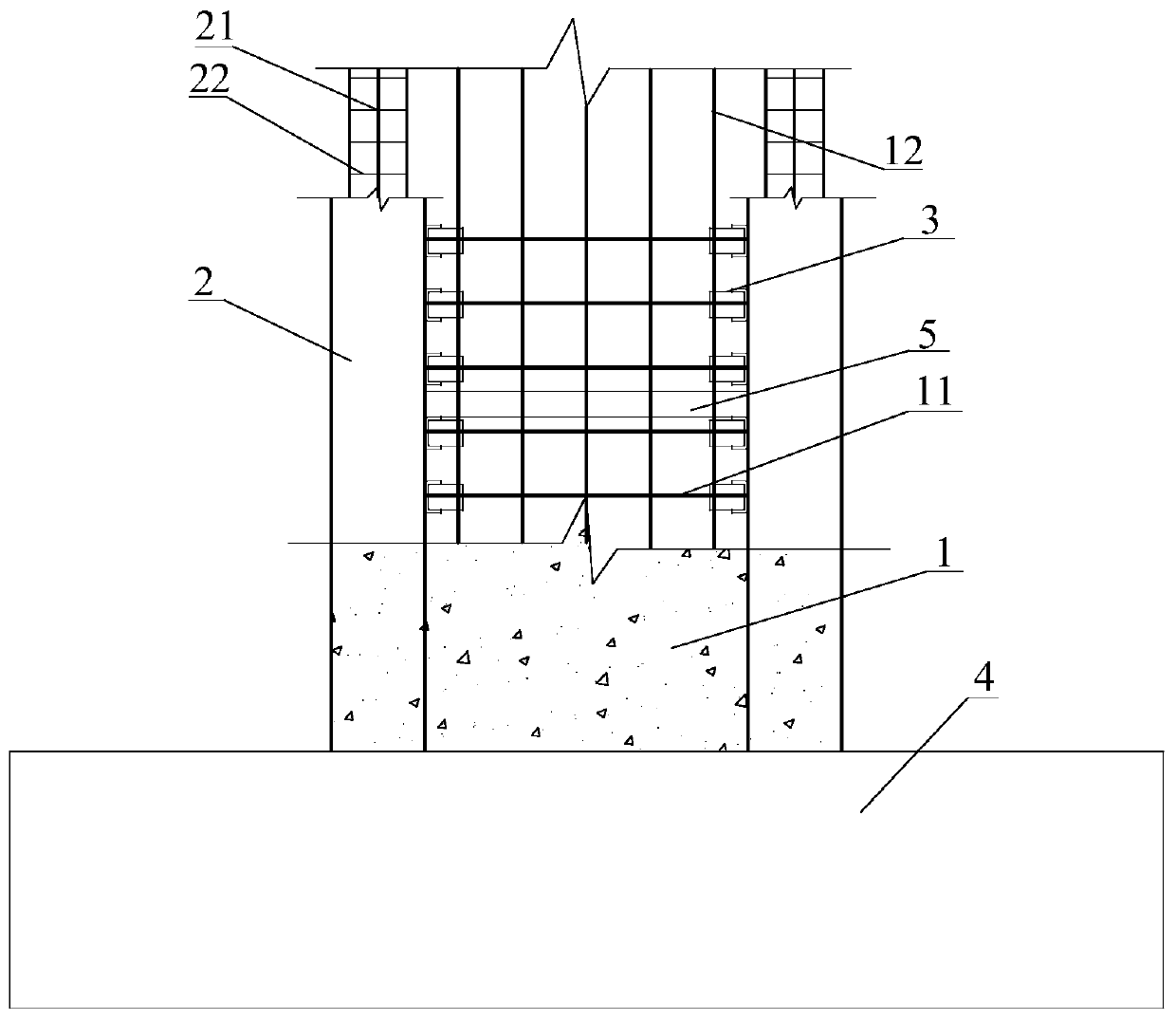

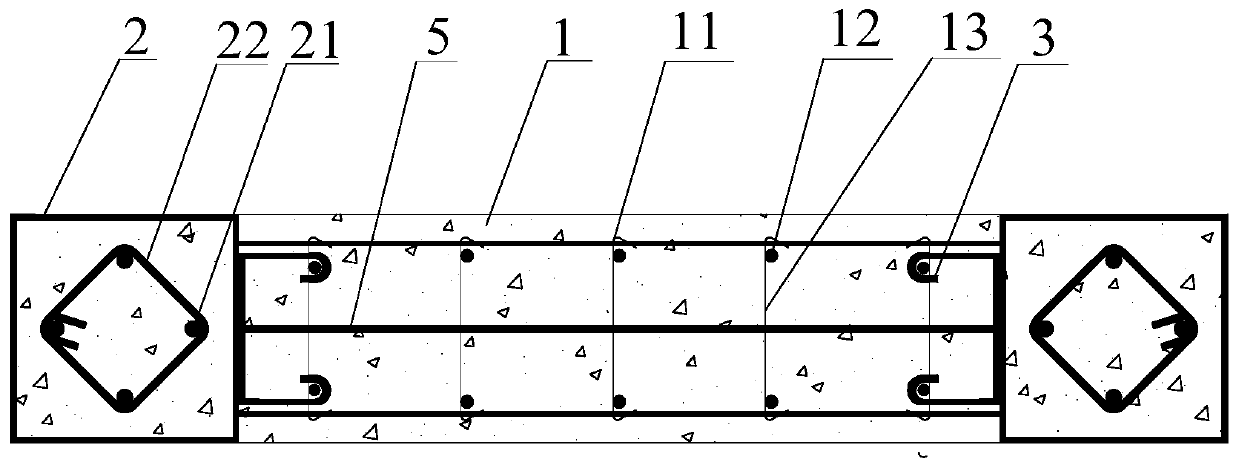

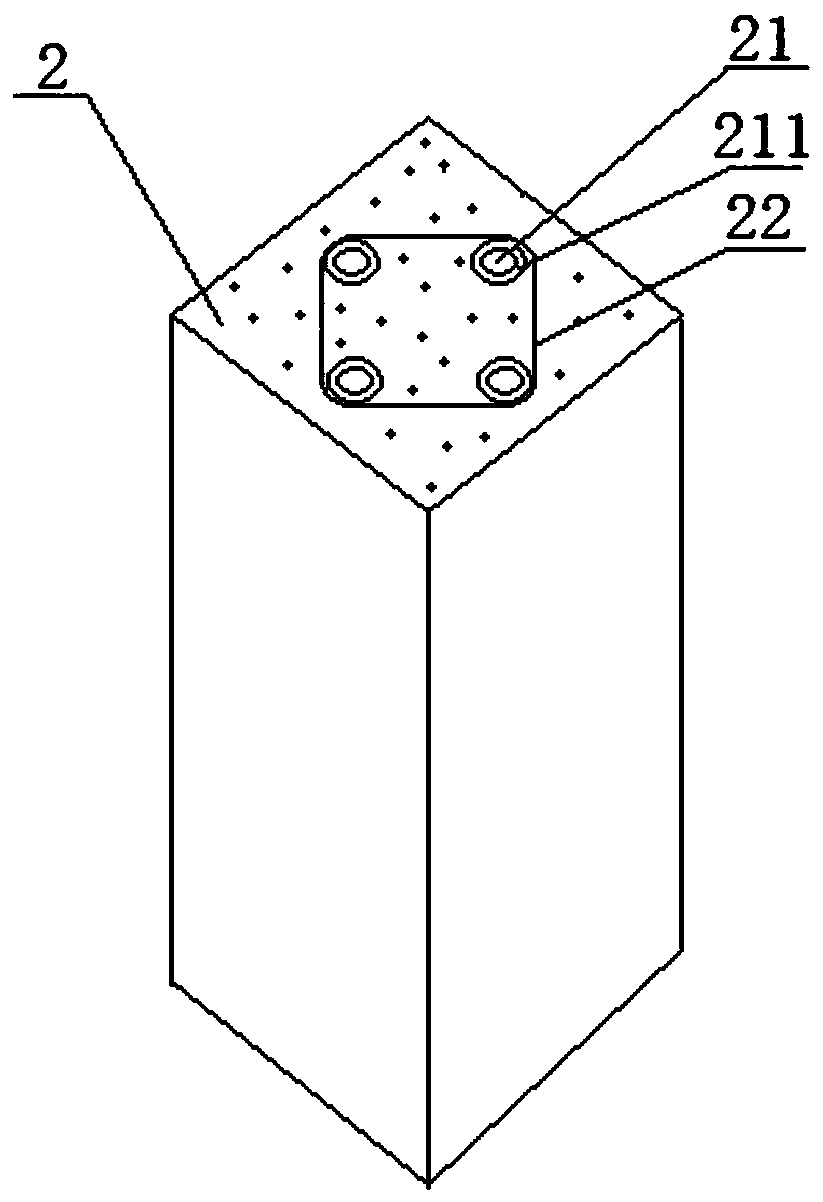

Damage-controllable high-strength concrete shearing wall and manufacturing method thereof

ActiveCN107859208AReduce crackingImprove rust and corrosion resistanceWallsHigh strength concreteResidual deformation

The invention provides a damage-controllable high-strength concrete shearing wall and a manufacturing method thereof. The damage-controllable high-strength concrete shearing wall comprises a high-strength concrete wall body, frame steel pipes are arranged on the two sides of the high-strength concrete wall body, and the inner sides of the frame steel pipes on the two sides are connected with the high-strength concrete wall body through anti-shearing connecting keys correspondingly; and the frame steel pipes are internally provided with a plurality of ultra-high-strength longitudinal bars, theultra-high-strength longitudinal bars are poured through high-strength concrete to be anchored, and the surfaces of the ultra-high-strength longitudinal bars are coated with anti-rust coatings. When the damage-controllable high-strength concrete shearing wall deforms greatly due to an earthquake or borne large acting force from the outside world, the ultra-high-strength longitudinal bars can be controlled within the elastic stage to deform for energy dissipation, residual deformation of the shearing wall after the earthquake is reduced, the self-reset capacity is provided for the shearing wall, cracking of the concrete can be delayed, a number of large cracks can be prevented from being caused in interfaces between the frame steel pipes and the high-strength concrete wall body, and thus the purposes that damage to a structure after the earthquake is small, and repairing is easy are achieved.

Owner:BEIJING UNIV OF TECH

Composite coating for high-performance grass mower

InactiveCN104789020AImprove rust and corrosion resistanceImprove wear resistanceAnti-corrosive paintsPolyester resinMaterials science

The invention discloses a composite coating for a high-performance grass mower. The composite coating is prepared from the following components in parts by weight: 3-8 parts of styrene, 7-12 parts of fluororesin, 15-22 parts of nanometer titania, 5-12 parts of talcum powder, 20-35 parts of carboxyl polyester resin, 15-18 parts of xylene, 4-8 parts of methylbenzene, 5-8 parts of blanc fixe, 3-5 parts of accessory ingredient and 15-20 parts of flatting agent. The composite coating for the high-performance grass mower provided by the invention is high in rust-proof corrosion resistant performance and high in wear-resisting property.

Owner:GUANGXI GAONONG MACHINERY

Processing technique of anti-rust and anti-corrosion hammer head

InactiveCN107345264AImprove rust and corrosion resistanceSimple processEpoxy resin coatingsEngineeringQuenching

The invention discloses a processing technique of an anti-rust and anti-corrosion hammer head. The processing technique comprises the steps of processing a semi-finished product, insulating, cooling, performing surface treatment, quenching, tempering, performing anti-corrosion pretreatment and performing anti-rust and anti-corrosion treatment. The processing technique of the anti-rust and anti-corrosion hammer head has the advantages of simple process, low manufacturing cost and good continuity of the process, and an anti-rust and anti-corrosion layer can be formed on the surface of the hammer head, so that the anti-rust and anti-corrosion performance of the hammer head is effectively improved.

Owner:JIANGSU JUNWEI ELECTRONICS TECH CO LTD

High anti-corrosion performance oil-based metal cutting fluid

InactiveCN106190474AImprove rust resistanceImprove the lubrication effectLubricant compositionSodium metasilicateSodium phosphates

The invention discloses high anti-corrosion performance oil-based metal cutting fluid which is prepared from raw materials in parts by weight, 20-30 parts of cycloalkane base oil, 5-15 parts of chlorinated paraffin, 2-8 parts of glycol, 3-9 parts of triethanolamine oleate ester, 1-4 parts of vulcanized oleic acid, 2-5 parts of sodium metasilicate, 3-6 parts of sodium phosphate, 1-4 parts of mechanical oil, 2-5 parts of cottonseed oil, 3-6 parts of polyoxyethylene alkylphenol, 1-5 parts of lead naphthenate, 2-5 parts of tall oil acid sodium salt, 3-6 parts of nonionic surfactants, 1-4 parts of modified anti-rust oil and 2-8 parts of compound corrosion inhibitors. The oil-based metal cutting fluid has excellent anti-rust, lubricating and anti-wear properties.

Owner:TIANCHANG RUNDA METAL ANTIRUST AUX

Rust-proof heat-resistant deformed steel and processing technology thereof

InactiveCN113583541AImprove high temperature oxidation resistanceHigh strengthFireproof paintsAnti-corrosive paintsManganeseHigh pressure water

The invention provides anti-rust heat-resistant deformed steel and a processing technology thereof. The deformed steel comprises a base material, a heat-resistant layer and an anti-rust layer; the base material comprises the following chemical components in percentage by mass: 0.2 to 1 percent of carbon, 2 to 3 percent of silicon, 8.2 to 10 percent of tungsten, 2 to 6 percent of molybdenum, 20 to 45 percent of chromium, 0.1 to 0.2 percent of cobalt, 0.5 to 1 percent of manganese, 0.2 to 0.6 percent of vanadium and the balance of iron; the processing technology of the base material comprises the steps of cleaning, dephosphorization, rolling, controlled cooling and straightening; specifically, a steel billet is placed in a cleaning solution, subjected to ultrasonic cleaning and drying and then heated to 1000-1200 DEG C in a furnace, the steel billet is discharged out of the furnace, cooled and then descaled through high-pressure water of 15-25 MPa, the steel billet is sent to a two-roller reversible rolling mill to be roughly rolled, then a universal continuous rolling unit is adopted for continuous rolling, controlled cooling and straightening, and the base material is obtained; the base material is subjected to sand blasting treatment, the surface of the base material is coated with the epoxy micaceous iron oxide intermediate paint, and then the epoxy micaceous iron oxide intermediate paint is coated with the anti-rust coating to serve as an anti-rust layer; and the antirust layer is coated with a heat-resistant coating as a heat-resistant layer.

Owner:常州市方正型钢有限公司

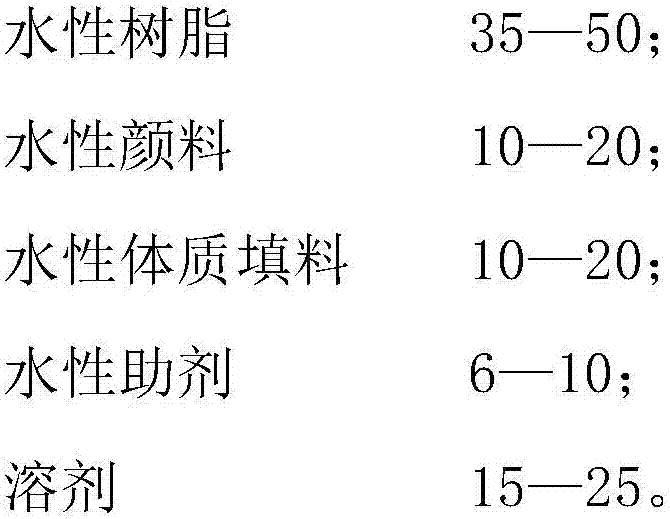

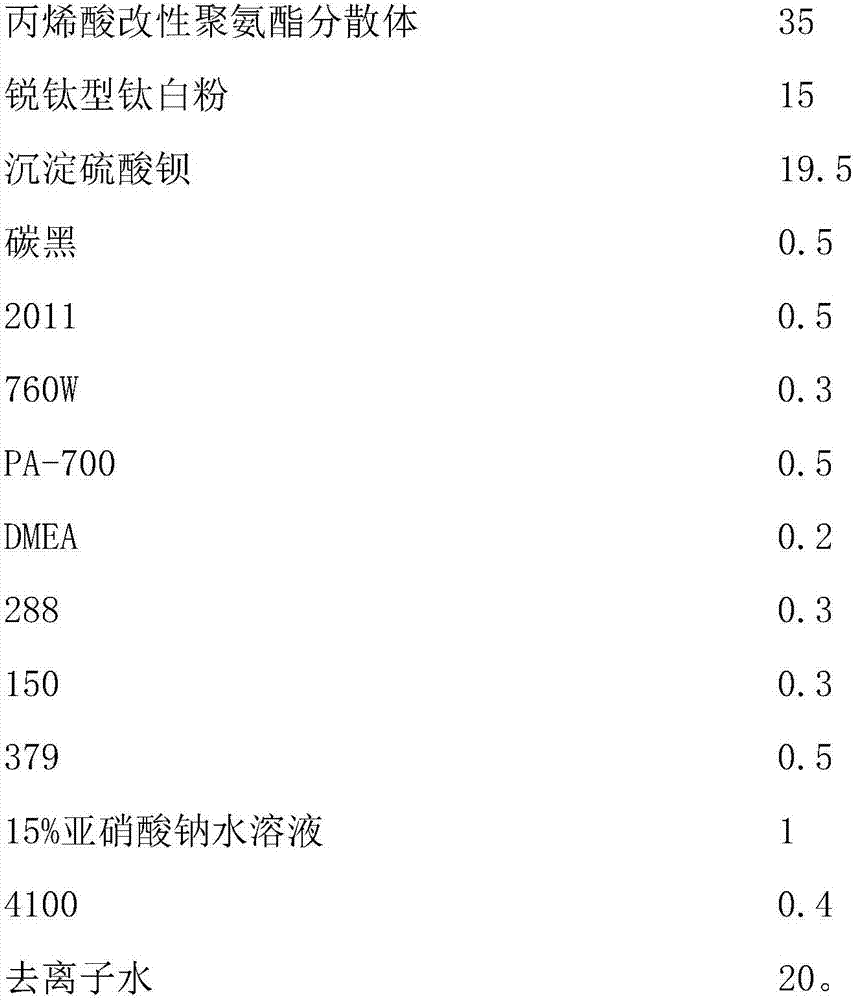

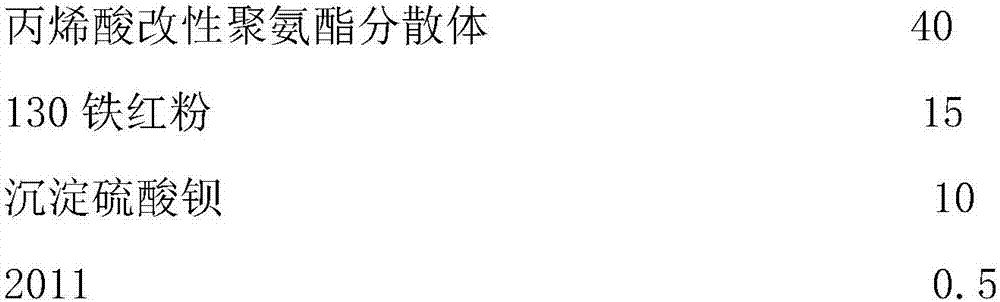

Water-based pre-coated primer as well as preparation method and application of primer

InactiveCN107880764AStrong adhesionGood flexibilityAnti-corrosive paintsPolyurea/polyurethane coatingsWater basedHazardous substance

The invention discloses water-based pre-coated primer which is prepared from the following raw materials in parts by weight: 35-50 parts of water-based resin, 10-20 parts of water-based pigments, 10-20 parts of water-based body filler, 6-10 parts of water-based aids and 15-25 parts of a solvent. The invention further provides a preparation method and application of the water-based pre-coated primer. The content of volatile organic compounds in the primer disclosed by the invention is far lower than the required limited quantity of harmful substances in water-based paint in the national standard.

Owner:HUNAN UNIV OF ARTS & SCI

Water-based metal primer-finish combined paint and preparation method thereof

The invention discloses water-based metal primer-finish combined paint. The water-based metal primer-finish combined paint comprises, by weight, 5-6% of water, 0.1-0.4% of magnesium aluminum silicate,0.5-0.6% of a dispersant, 0.1-0.2% of a wetting agent, 0.1-0.3% of a defoamer, 0.2-0.5% of a pH regulator AMP-95, 12-18% of R-760 titanium dioxide, 2-5% of zinc phosphate, 3-5% of barium sulfate of 1000 meshes, 1-3% of mica powder of 1000 meshes, 50-55% of an water-based acrylic industrial emulsion, 2-3% of a film former Texanol, 0.5-1% of an anti-flash rust agent, 0.1-0.5% of a preservative, 0.1-0.5% of a polyurethane thickener, 0.1-0.2% of a substrate wetting agent and the balance of water.

Owner:CHUZHOU MAISITE NEW BUILDING MATERIAL

Lubricating oil for mining machinery

PendingCN112899056AImprove wear resistanceImprove rust and corrosion resistanceLubricant compositionPoly methacrylateSilane coupling

The invention discloses lubricating oil for mining machinery, wherein the lubricating oil is prepared from the following ingredients in parts by weight: 60 to 70 parts of mineral base oil, 20 to 25 parts of biological base oil, 2 to 3 parts of nanometer copper powder, 4 to 6 parts of nanometer silicon dioxide, 25 to 30 parts of talcum powder, 8 to 10 parts of polymethacrylate, 8 to 10 parts of a silane coupling agent, 2 to 3 parts of polydimethylsiloxane, 5 to 6 parts of sodium ascorbate, and 5 to 8 parts of an anticorrosive agent. The lubricating oil for mining machinery provided by the invention is good in wear resistance and excellent in corrosion resistance.

Owner:LOUDI DINGHONG AUTOMATION EQUIP

A kind of preparation method of iron-silicon soft magnetic alloy powder

The invention provides a preparation method of iron-silicon soft magnetic alloy powder. The preparation method comprises the following steps: (1) preparing alloy through the following raw materials in percentage by weight: 5.0 to 6.2% of Si, 2.0 to 4.0% of Cr, 0.05 to 0.15% of P, and the balance Fe; (2) feeding the raw materials into a crucible, smelting through a vacuum induction furnace, and cooling molten alloy into thin sheets in a rapid solidification manner; (3) crushing the thin sheets; dipping with liquid nitrogen; grinding through a ring hammer; and sieving to obtain fine alloy particle powder; (4) grinding through a low-speed stirring grinding machine, and shaping the powder; (5) thermally processing the powder under a reduction atmosphere, namely, heating to reach the temperature of 780 to 900 DEG C, and maintaining the temperature for 2 to 5 hours; and (6) sieving to obtain fine particular iron-silicon soft magnetic alloy powder meeting the requirement of a user on particle size. With the adoption of the method, the fine iron-silicon soft magnetic alloy powder which has a good appearance and is shaped like spheres can be prepared; the demand of preparing an integrally-formed inductor can be met.

Owner:SOUTH CHINA AGRI UNIV

Discharge-free recyclable water-based cutting fluid and preparation method thereof

Owner:HUBEI CHENGXIANG TECH

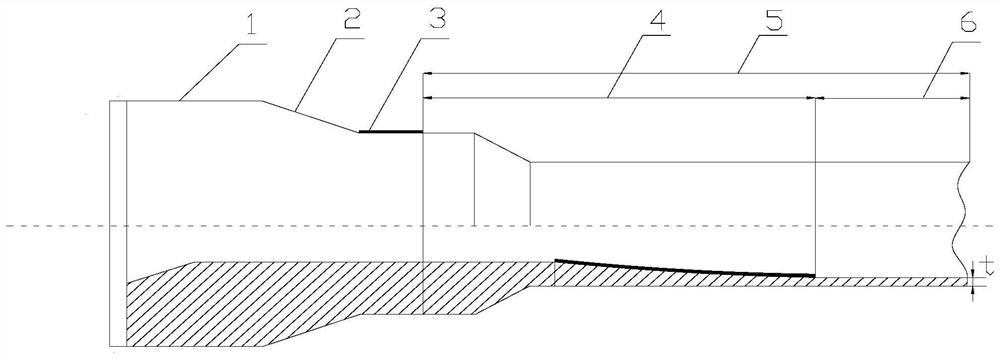

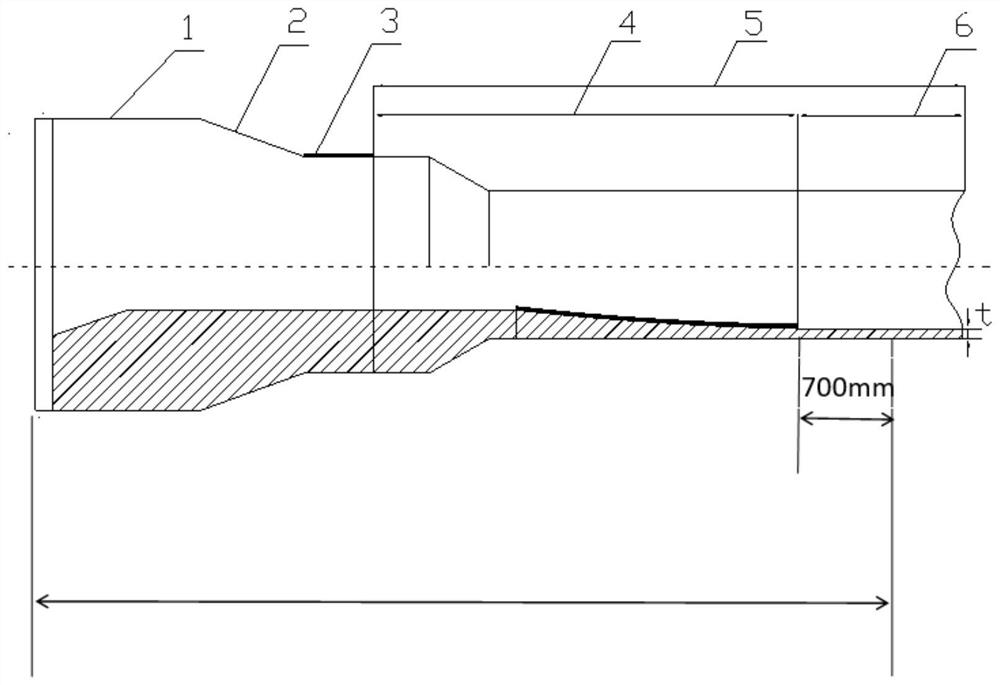

Pre-bending process of straight seam submerged arc welded steel pipe production line

ActiveCN105598224BImprove rust and corrosion resistanceReduce investmentMetal-working feeding devicesPositioning devicesProduction lineEngineering

The invention discloses a pre-bending process for a longitudinal submerged arc welding pipe production line. According to the process, operation is carried out on a longitudinal steel pipe welding pre-bending device; the longitudinal steel pipe welding pre-bending device comprises conveying roll tables which are arranged in parallel, a sucker hoisting conveyor is arranged at the upstream of the conveying roll tables, and a steel pipe pre-bending forming machine is arranged at the downstream of the conveying roll tables; the sucker hoisting conveyor comprises a hoisting cross beam and a vacuum sucker; and the steel pipe pre-bending forming machine comprises a pre-bent upper mold, a pre-bent lower mold and a pre-bent fixture. The process comprises the following steps: a feeding step in which the upper surface of a pre-bent steel plate is sucked by the vacuum sucker to move toward the downstream of the conveying roll tables; a bending step in which the pre-bent upper mold and the pre-bent lower mold of the steel pipe pre-bending forming machine make forward motion; and a resetting step. Relative sliding and friction between the pre-bent steel plate and conveying equipment can be reduced in the pre-bent steel plate feeding process, scratches generated on the surface of the pre-bent steel plate can be avoided, and the anti-rust and anti-corrosion capability of a longitudinal steel pipe can be improved.

Owner:ANHUI HONGLU STEEL CONSTR (GROUP) CO LTD

Clump weight for head of golf club

InactiveCN1280436CImprove rust and corrosion resistanceIncrease the uniformity of the glossy surfaceGolf clubsRacket sportsTungstenIron–nickel alloy

Owner:FUSHENG IND CO LTD

Composite coating for spraying machines

InactiveCN104817860AImprove rust and corrosion resistanceNot easy to wearAnti-corrosive paintsRustAcetone

The invention discloses a composite coating for spraying machines. The composite coating is prepared from, by mass, 3-8 parts of allyl heptanoate, 1-3 parts of acetylacetone selenium, 3-10 parts of 3-chloro-2- carboxylpropyltrimethylammonium chloride, 8-17 parts of maleic anhydride, 15-20 parts of molybdenum dioxide, 16-25 parts of aluminium triphosphate, 1-3 parts of kieselguhr, 20-35 parts of chlorosulfonated polyethylene and 30-45 parts of air-drying organic silicon resin. The composite coating for spraying machines is high in rust protection and corrosion resistant performances and difficult to wear.

Owner:GUANGXI GAONONG MACHINERY

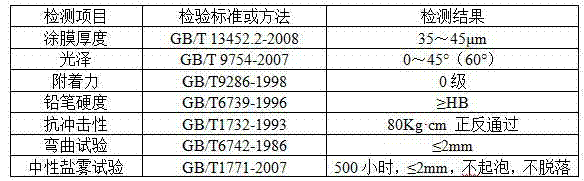

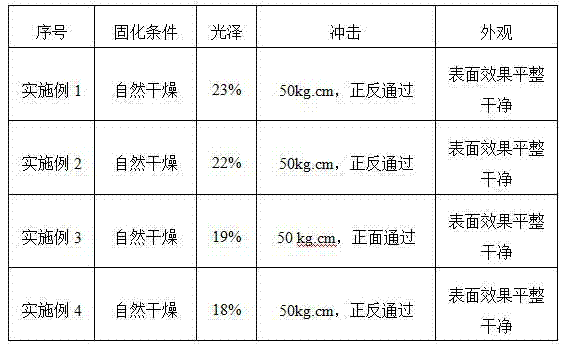

A kind of environment-friendly anticorrosion water-based primer coating and preparation method thereof

ActiveCN103773175BGood adhesionLow VOC contentAnti-corrosive paintsEpoxy resin coatingsZinc phosphateEmulsion

The invention discloses an environment-friendly anticorrosion waterborne primer paint. The environment-friendly anticorrosion waterborne primer paint comprises the following components in parts by weight: 35-50 parts of waterborne emulsion, 0.5-1 part of waterborne dispersing agent, 0.2-0.5 part of waterborne defoaming agent, 10-35 parts of filler, 1-3 parts of silicon dioxide, 2-3 parts of anti-flash-rust agent, 10-15 parts of zinc phosphate, 1-1.5 parts of organic bentonite, 0.2-0.5 part of pH value regulator, 0.2-0.5 part of thickening agent, 0.5-1 part of film-forming additive, 8-15 parts of pigment and 10-13 parts of water. The invention also discloses a preparation method of the paint. The paint has strong anticorrosion capacity, strong adhesion and high curing speed.

Owner:清远市贝客音涂料有限公司

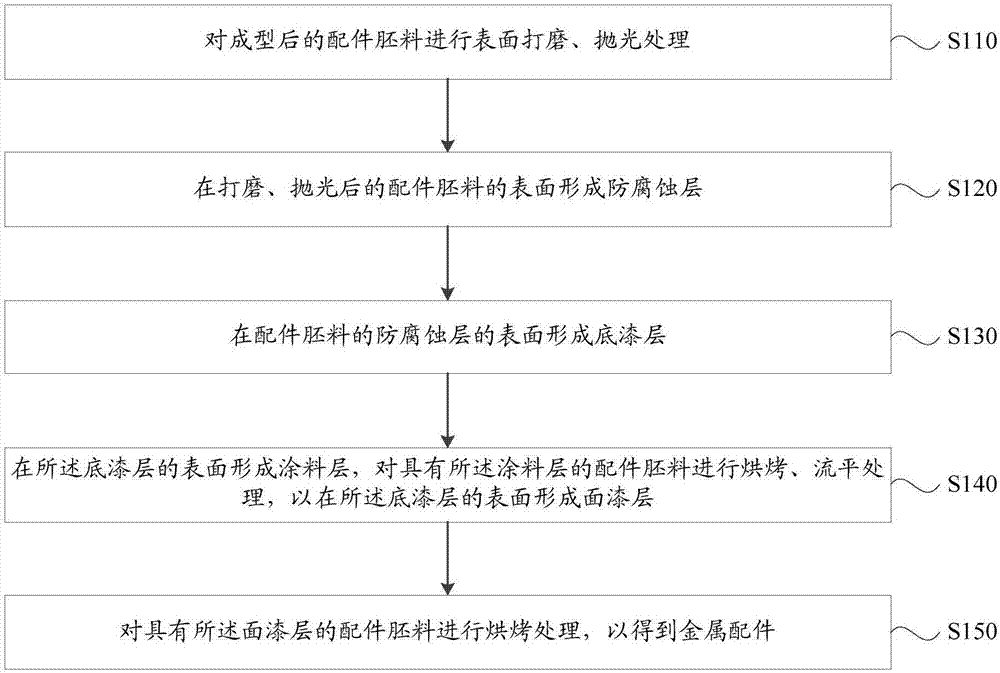

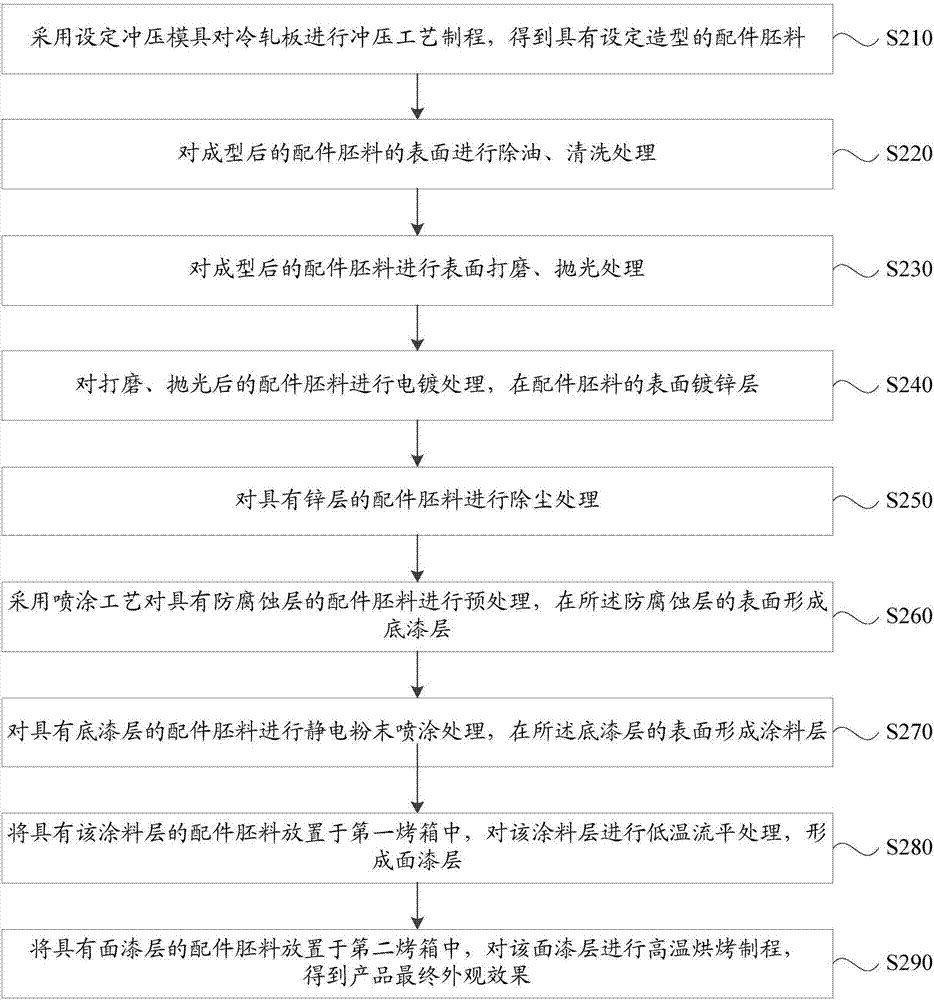

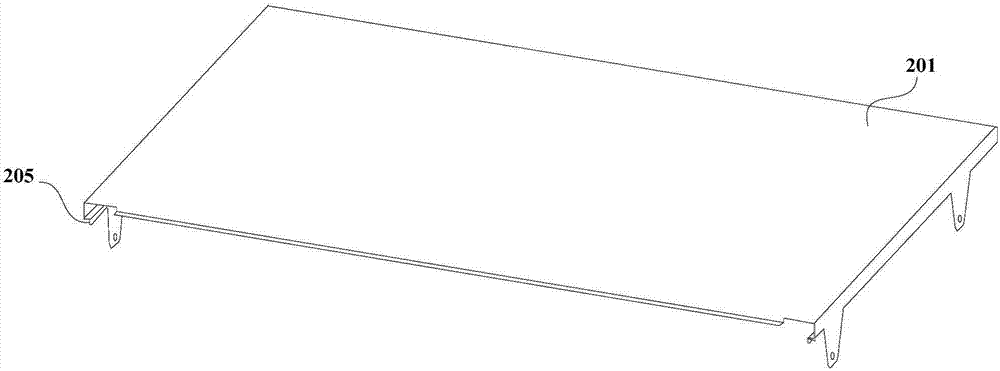

Preparation method for metal accessory, metal accessory and mobile terminal

InactiveCN107051839AImprovement of appearance quality and yieldImprove rust and corrosion resistancePretreated surfacesCoatingsComputer terminalCorrosion resistant

The embodiment of the invention discloses a preparation method for a metal accessory, a metal accessory and a mobile terminal. The method comprises the steps that a formed accessory blank is subjected to surface sanding and polishing treatment; an anti-corrosion layer is formed on the surface of the accessory blank obtained after sanding and polishing; a primer layer is formed on the surface of the anti-corrosion layer of the accessory blank; a coating layer is formed on the surface of the primer layer, and the accessory blank with the coating layer is subjected to baking and leveling treatment, so that a finishing coat layer is formed on the surface of the primer layer; the accessory blank with the finishing coat layer is baked to obtain the metal accessory. According to the method, the problems that a metal accessory prepared through a traditional technology is low in appearance quality yield, poor in appearance expressive force and the like can be solved, and the effects of promoting the appearance quality yield and the appearance expressive force of the metal accessory and improving rustproof and corrosion-resistant abilities of the surface of the metal accessory are achieved.

Owner:GUANGDONG OPPO MOBILE TELECOMM CORP LTD

A self-resetting high-strength concrete shear wall and its manufacturing method

The invention provides a damage-controllable high-strength concrete shearing wall and a manufacturing method thereof. The damage-controllable high-strength concrete shearing wall comprises a high-strength concrete wall body, frame steel pipes are arranged on the two sides of the high-strength concrete wall body, and the inner sides of the frame steel pipes on the two sides are connected with the high-strength concrete wall body through anti-shearing connecting keys correspondingly; and the frame steel pipes are internally provided with a plurality of ultra-high-strength longitudinal bars, theultra-high-strength longitudinal bars are poured through high-strength concrete to be anchored, and the surfaces of the ultra-high-strength longitudinal bars are coated with anti-rust coatings. When the damage-controllable high-strength concrete shearing wall deforms greatly due to an earthquake or borne large acting force from the outside world, the ultra-high-strength longitudinal bars can be controlled within the elastic stage to deform for energy dissipation, residual deformation of the shearing wall after the earthquake is reduced, the self-reset capacity is provided for the shearing wall, cracking of the concrete can be delayed, a number of large cracks can be prevented from being caused in interfaces between the frame steel pipes and the high-strength concrete wall body, and thus the purposes that damage to a structure after the earthquake is small, and repairing is easy are achieved.

Owner:BEIJING UNIV OF TECH

Fireproof coating for exhaust equipment

InactiveCN105949838AGood dispersionImprove permeabilityFireproof paintsAnti-corrosive paintsMethacrylateZirconate

The invention discloses a fireproof coating for exhaust equipment. The coating is made from the following raw materials: coal ash, a fluorocarbon resin, polyacrylamide, n-butyl acetate, methacrylate, a polyurethane resin, an acrylic acid leveling agent, aluminium powder, floaters, expanded mica, styrene, azodiisobutyronitrile, silica powder, zinc methacrylate, aluminum dihydrogen tripolyphosphate, a zirconate coupling agent, sulphur, diethanol amine, sawdust powder and a proper amount of absolute ethanol. The coating has preferable fire retardance and weather resistance, is high in strength and excellent in storage performance, and is convenient to apply. The coating can be operated at a high-temperature environment for a long time and is not easy to spoil. The coating has excellent overall performance and obvious cost advantage, and has bright application prospects.

Owner:CHUZHOU VOCATIONAL & TECHN COLLEGE

A kind of film anticorrosion electromagnetic wire and its preparation method

ActiveCN107910115BImprove rust and corrosion resistanceImprove protectionInsulated cablesCable/conductor manufactureInsulation layerCopper wire

The invention discloses a thin-film anti-corrosion electromagnetic wire. After the alloy copper wire is treated in a thin-film anti-corrosion solution, the surface of the alloy copper wire is covered with an insulating layer by means of sol deposition. The thin-film anti-corrosion solution of the present invention uses alcohol ester Twelve is a film-forming aid, blended with phosphate, silicate, and sulfate, which can effectively improve the rust and corrosion resistance of the alloy, and the added calcium acetylacetonate is blended with stearic acid to form a film The method is coated on the surface of the alloy, which has a good effect of heat resistance and anticorrosion; the present invention uses aluminum isopropoxide as a precursor, hydrolyzes in an alkaline solution, deposits it on the surface of the alloy, and then sinters to realize the sol The coated alloy electromagnetic wire has a very good protection effect on the alloy.

Owner:安徽天大铜业有限公司

Heat-preservation, heat-insulation, anti-rust and anti-corrosion coating for chassis

PendingCN114806357AImprove water resistanceWith anti-rust functionAnti-corrosive paintsEpoxy resin coatingsEpoxySilicic acid

The invention relates to the field of automobile anti-corrosion materials, in particular to a heat-preservation, heat-insulation, anti-rust and anti-corrosion coating for an automobile chassis, which is prepared by the following steps: step 1, adding 3-6 parts of nano silicon dioxide, 1-2 parts of dispersing agent and 10-15 parts of deionized water, and stirring and uniformly dispersing under high-speed mechanical stirring; the rotating speed of the high-speed mechanical stirring is 1,800 to 2,000 rpm (revolutions per minute); step 2, adding 50-70 parts of acrylic acid modified alkyd resin and 30-40 parts of epoxy resin into the uniform material obtained in the step 1, stably heating the working temperature to 50 + / -5 DEG C, and uniformly stirring at the rotating speed of 600-800rpm; 3, after the mixture in the step 2 is cooled to the room temperature, 0.5-1 part of composite magnesium aluminum silicate and 1-2 parts of dodecanol ester alcohol are added, and the mixture is evenly mixed at the room temperature. According to the paint, the acrylic acid modified alkyd resin and the epoxy resin are used as substrates, the nano silicon dioxide is added for combined use, and the paint adopts multi-component substances for combined use, so that the paint has the functions of heat preservation, heat insulation, rust prevention and corrosion prevention.

Owner:江苏天时新材料科技有限公司

Corrosion-resistant and long-fatigue-life drill rod and preparation method thereof

InactiveCN112855036AImprove wear resistanceImprove fatigue resistanceDrilling rodsPretreated surfacesStress concentrationOil field

The invention discloses a corrosion-resistant and long-fatigue-life drill rod and a preparation method thereof, and belongs to the technical field of corrosion prevention of drill rods and coatings. For a stress concentration part, namely a pipe body thickening transition disappearance area, of a drill rod frequent failure area, outer coating corrosion prevention of a specific material is conducted on a specific area section, so that breakthrough is made in the aspects of improving the abrasion resistance, fatigue resistance, corrosion resistance and the like of the drill rod, and the purpose of preventing the drill rod pipe body thickening transition disappearance area from losing efficacy in advance is achieved; the corrosion and fatigue failure problems of the most common position of an existing drill rod is solved, and the service fatigue life of the drill rod is prolonged; and a specific area is designed at the stress concentration part instead of the outer surface of the whole drill rod, the cost is saved, and a composite coating is made of a nano composite heavy rust-proof anti-corrosion coating, so that the composite coating is super-strong in anti-corrosion performance, good in effect, low in cost and convenient for large-scale popularization and application in oil field production.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com