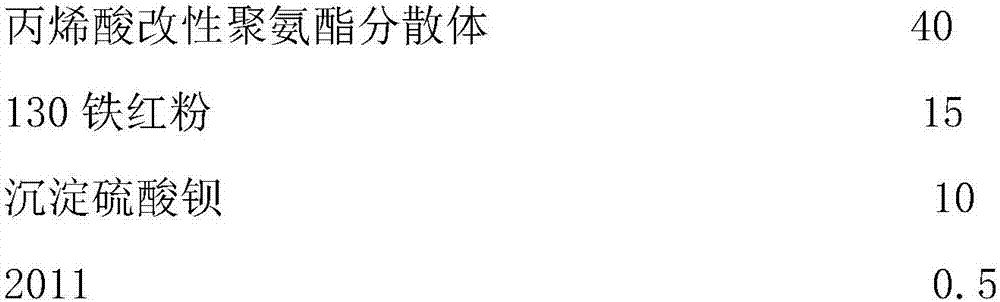

Water-based pre-coated primer as well as preparation method and application of primer

A pre-primer, water-based technology, used in primers, coatings, anti-corrosion coatings, etc., can solve problems such as high VOC content and environmental pollution, achieve fast drying speed and hardness increase speed, excellent hardness, reduce pores and The effect of pores

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

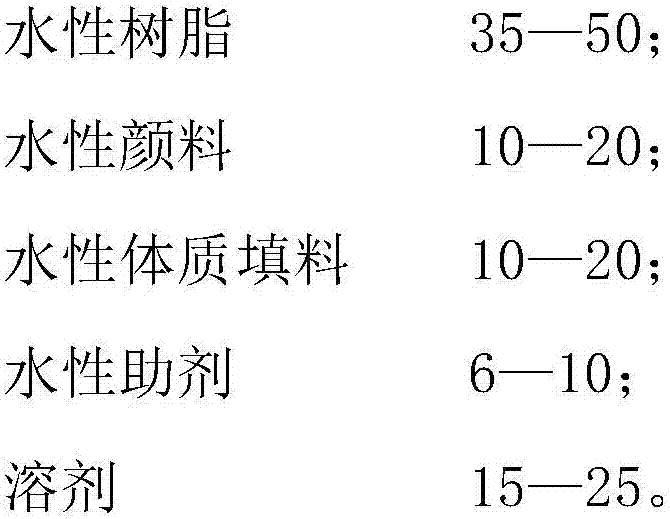

[0028] The water-based precoat primer comprises the following raw materials prepared by weight:

[0029]

[0030] The preparation steps of this embodiment are

[0031] S1. After preparing the materials, add deionized water, DMEA, 2011, 760W, PA-700, anatase titanium dioxide, precipitated barium sulfate, and carbon black to the reactor in sequence, and stir evenly at a medium speed (90-110 rpm) ;

[0032] S2. Disperse the uniformly stirred slurry at high speed (300-320 rpm) for 30 minutes, and then grind it into a sand mill to a qualified fineness.

[0033] S3, add water-based acrylic modified polyurethane dispersion, 379, 15wt% sodium nitrite aqueous solution, 4100 in the ground slurry, first medium speed (90-110 rev / min) stir evenly; Add 288 and 150 under stirring, then disperse at high speed for 30 minutes, and adjust the viscosity to get the finished product.

[0034] The water-based pre-coating primer prepared in this embodiment is sprayed on the surface of structura...

Embodiment 2

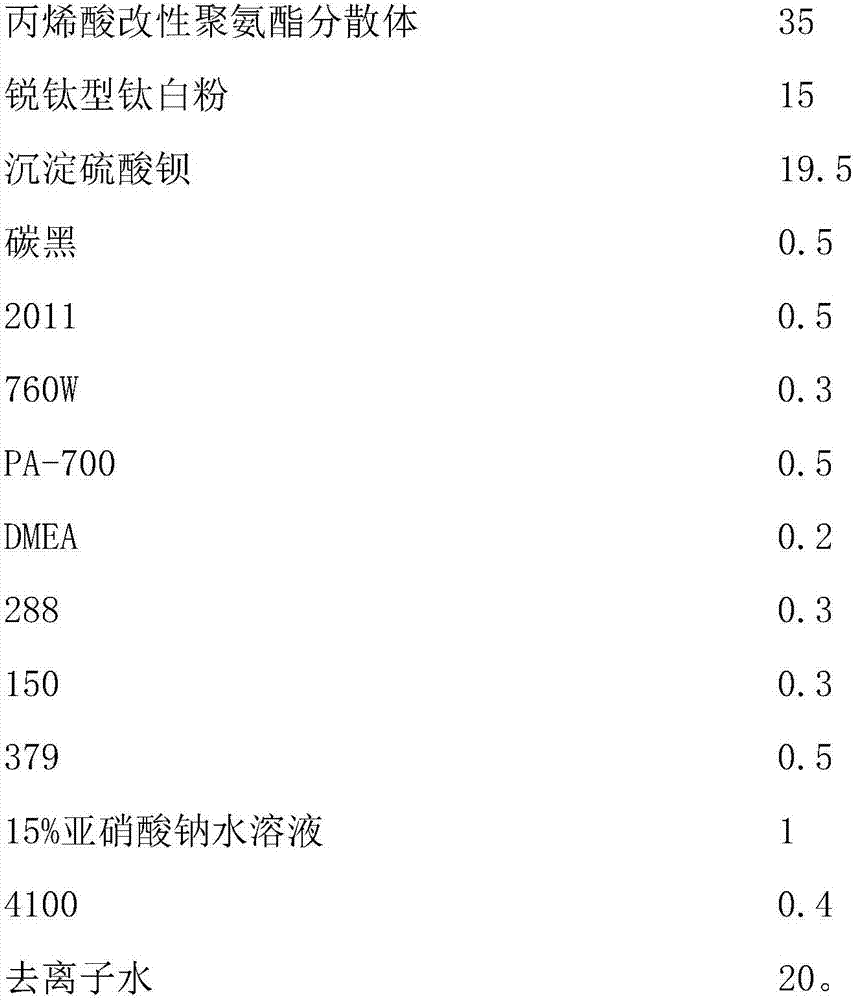

[0038] The water-based precoat primer comprises the following raw materials prepared by weight:

[0039]

[0040]

[0041] The preparation steps of this embodiment are:

[0042] S1. After preparing the materials, add deionized water, DMEA, 2011, PA-700, 130 iron red powder, and precipitated barium sulfate to the reactor in turn, and stir evenly at a medium speed (90-110 rpm);

[0043] S2. Disperse the evenly stirred slurry at high speed (300-320 rpm) for 25-35 minutes, and then grind it into a sand mill to a qualified fineness.

[0044] S3, add water-based acrylic modified polyurethane dispersion, Ruibao 60, 15wt% sodium nitrite aqueous solution, 3075, 3076A in the ground slurry, first medium speed (90-110 rpm) stir evenly; 50-60 rev / min), add 288 and 168 under stirring, then disperse at high speed for 30 minutes, and adjust the viscosity to get the finished product.

[0045] The water-based pre-coating primer prepared in this embodiment is sprayed on the surface of st...

Embodiment 3

[0050] The water-based precoat primer comprises the following raw materials prepared by weight:

[0051]

[0052] The preparation steps of this embodiment are

[0053] S1. After preparing the materials, add deionized water, DMEA, 2011, 6091, PA-700, anatase titanium dioxide, carbon black, 1250 mesh talc powder into the reactor in sequence, and stir at a medium speed (90-110 rpm) Uniform;

[0054]S2. Disperse the uniformly stirred slurry at high speed (300-320 rpm) for 30 minutes, and then grind it into a sand mill to a qualified fineness.

[0055] S3. Add water-based acrylic modified polyurethane dispersion, Ruibao 60, 15wt% sodium nitrite aqueous solution, 4100 to the ground slurry, and stir evenly at a medium speed (90-110 rpm); 60 rev / min) under stirring, add XS-83 and 168, then disperse at high speed for 30 minutes, adjust the viscosity to get the finished product.

[0056] The water-based pre-coating primer prepared in this embodiment is sprayed on the surface of st...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com