Corrosion-resistant and long-fatigue-life drill rod and preparation method thereof

A fatigue life and corrosion resistance technology, applied in drill pipe, drilling equipment, drill pipe, etc., can solve the problem of high economic cost, and achieve the effect of saving cost, good effect and improving wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

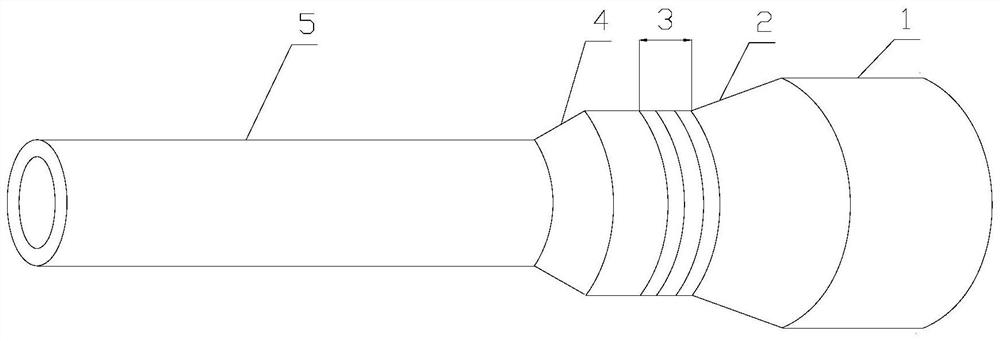

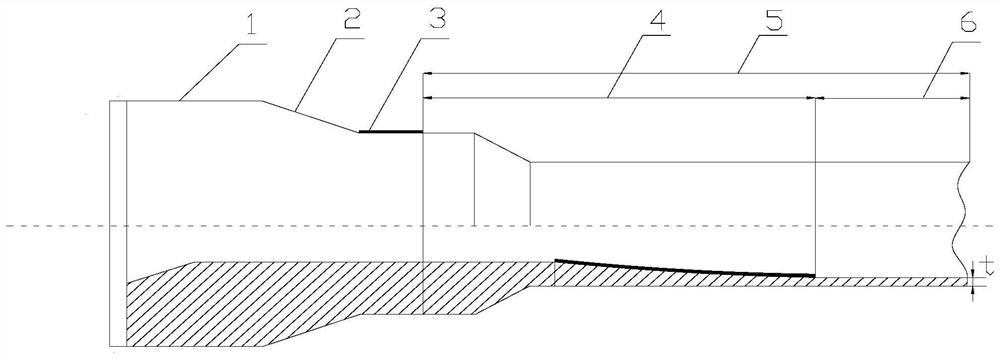

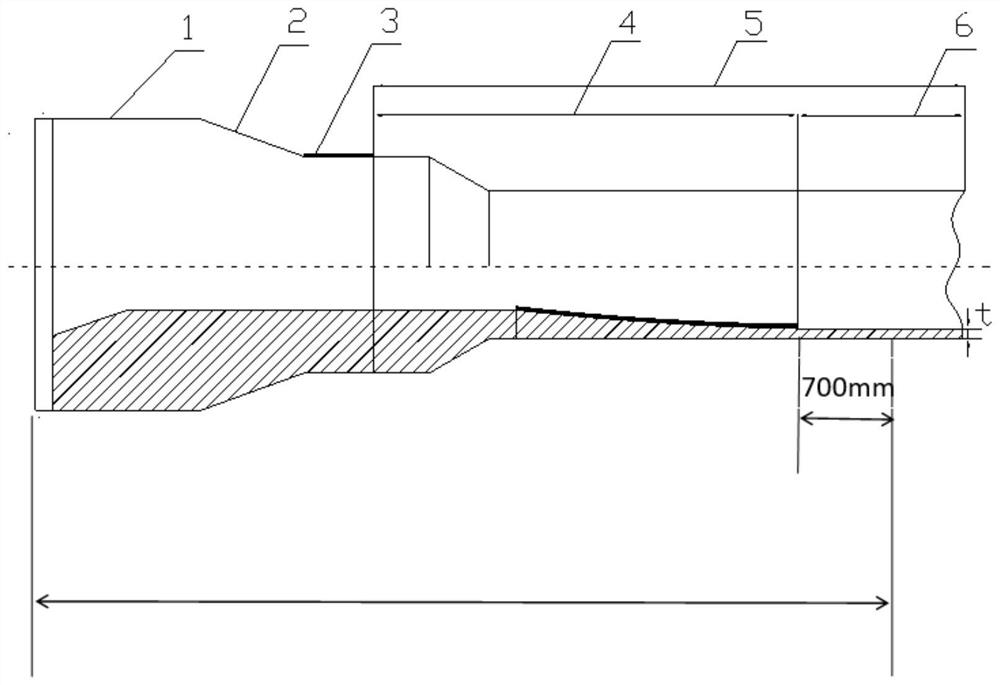

[0039] A drill pipe with corrosion resistance and high fatigue life, including a rod body 5, the rod body 5 includes a pipe body 6 and a thickened area 4 connected to the pipe body 6, and the other end of the thickened area 4 passes through the welding neck 3 and the shoulder 2 in sequence A joint 1 is connected; a specific area is provided on the drill pipe, and the specific area includes the joint 1, the shoulder 2, the welding neck 3 and the thickened area 4, and also includes the distance between 0~ 700mm area segment;

[0040] A composite coating is provided on a specific area of the drill pipe, and the composite coating is a nano-composite heavy anti-rust and anti-corrosion material coated on the surface of the specific area, and the particle size of the composite coating is 40-80nm.

Embodiment 2

[0042] like figure 1 and figure 2 As shown, the structure of the drill pipe of the present invention is consistent with that of the traditional drill pipe, including the joint 1, the shoulder 2, the welding neck 3 and the rod body 5, and the rod body 5 includes the thickened area 4 and the pipe body 6.

[0043] The nano-composite heavy-duty anti-rust and anti-corrosion paint is applied to a specific area on the outer surface of the drill pipe. The operation process mainly includes:

[0044] Pretreatment before coating: Phosphating treatment on the surface of the drill pipe.

[0045] Do not apply any grease or protective grease during the pretreatment process to ensure that the phosphating surface is dry and free of debris. Check the surface of the drill pipe after cleaning, and start the coating operation after confirming that the cleaning quality is qualified.

[0046] Coating: Fully shake the nano-composite heavy anti-rust and anti-corrosion material (bottled), and try t...

Embodiment 3

[0048] A method for preparing a drill pipe with corrosion resistance and high fatigue life, comprising the steps of:

[0049] 1) Phosphating pretreatment is carried out on the surface of the drill pipe;

[0050] 2) The surface of the pretreated drill pipe in step 1) is coated with a nano-composite heavy anti-rust and anti-corrosion material, and after the coating is left to stand until the surface of the drill pipe is dry, a corrosion-resistant and extrusion-resistant drill pipe is obtained.

[0051] The specific operation of the phosphating pretreatment is as follows: the drill pipe is soaked in antirust water after degreasing and rust removal, and then soaked in the phosphating solution for 28-35 minutes.

[0052] The concrete operation of step 2) is:

[0053] 21) Stir the nano-composite heavy anti-rust and anti-corrosion material evenly;

[0054] 22) Immerse the brush in the nano-composite heavy anti-rust and anti-corrosion material in step 21) for 3-7 seconds and then ta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com