Environment-friendly anticorrosion waterborne primer paint and preparation method thereof

A water-based primer, an environmentally friendly technology, applied in the direction of anti-corrosion coatings, epoxy resin coatings, coatings, etc., can solve the problems of anti-corrosion, weak adhesion, etc., to improve the ability of anti-rust and anti-corrosion, high adhesion, Effect of low VOC content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

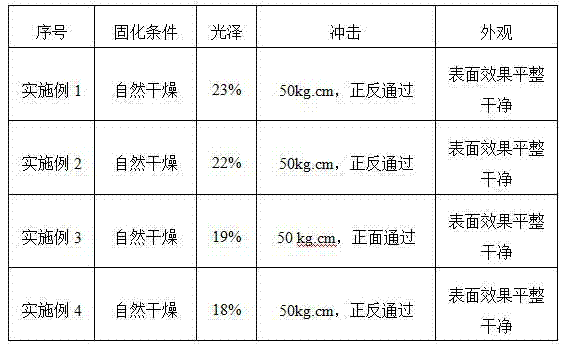

Embodiment 1

[0044] Water-based iron red primer paint, its components and parts by weight are: (unit: part)

[0045] water 10

[0046] Water-based emulsion (TG point 95°C) 35

[0047] Water-based dispersant 0.5

[0048] Water-based defoamer 0.3

[0049] Water-based talcum powder (1250 mesh) 20

[0050] Heavy calcium (1250 mesh) 12.8

[0051] Iron Oxide Red 13

[0052] Silica 1

[0053] Anti-flash rust agent 2.5

[0055] Organic bentonite 1

[0056] pH regulator 0.2

[0057] Thickener 0.2

[0058] Coalescing aid 0.5

[0059] Preparation:

[0060] (1) Weigh water-based emulsion, water-based dispersant, water-based defoamer, heavy calcium, water-based talcum powder, iron oxide red, silicon dioxide, anti-flash rust agent, zinc phosphate, water and organic bentonite according to the above ratio, and place in Mixing bowl, mix well.

[0061] (2) Add the mixed material into a vertical sand mill and grind for 1 hour until the fineness is ≤35um.

[0062] ...

Embodiment 2

[0066] Different from Example 1: (unit: part)

[0067] water 10

[0068] Water-based emulsion (TG point 90°C) 50

[0069] Aqueous Dispersant 1

[0070] Water-based defoamer 0.5

[0071] Water-based talcum powder (1250 mesh) 20

[0072] Heavy calcium (1250 mesh) 10

[0073] Iron Oxide Red 13

[0074] Silica 2

[0075] Anti-flash rust agent 2.5

[0076] Zinc phosphate 15

[0077] Organic bentonite 1

[0078] pH regulator 0.2

[0079] Thickener 0.2

[0080] Coalescing aid 0.5.

Embodiment 3

[0082] Off-white water-based primer paint, its components and parts by weight are: (unit: part)

[0083] water 12

[0084] Water-based emulsion (TG point 100°C) 36

[0085] carbon black 2

[0086] Water-based dispersant 0.5

[0087] Water-based defoamer 0.3

[0088] Water-based talcum powder (1250 mesh) 14.3

[0089] Heavy calcium (1250 mesh) 10

[0090] Titanium dioxide 10

[0091] Silica 1

[0092] Anti-flash rust agent 2

[0093] Zinc phosphate 10

[0094] Organic bentonite 1

[0095] pH regulator 0.2

[0096] Thickener 0.2

[0097] Coalescing aid 0.5

[0098] Preparation:

[0099] (1) Weigh water-based emulsion, carbon black, water-based dispersant, water-based defoamer, heavy calcium, water-based talcum powder, titanium dioxide, silicon dioxide, anti-flash rust agent, zinc phosphate, water and organic bentonite according to the above ratio, Place in a mixing tank and mix thoroughly.

[0100] (2) Put the mixed material into a vertical sand mill and grind f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| solid content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com