Emission-free reusable waterborne cutting fluid and preparation method thereof

A cutting fluid, no-discharge technology, applied in the petroleum industry, lubricating compositions, etc., can solve the problems of decreased anti-rust performance, unstable cutting fluid performance, and increased production costs, preventing the formation of cutting nodules, and achieving excellent lubrication and cooling. durability and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

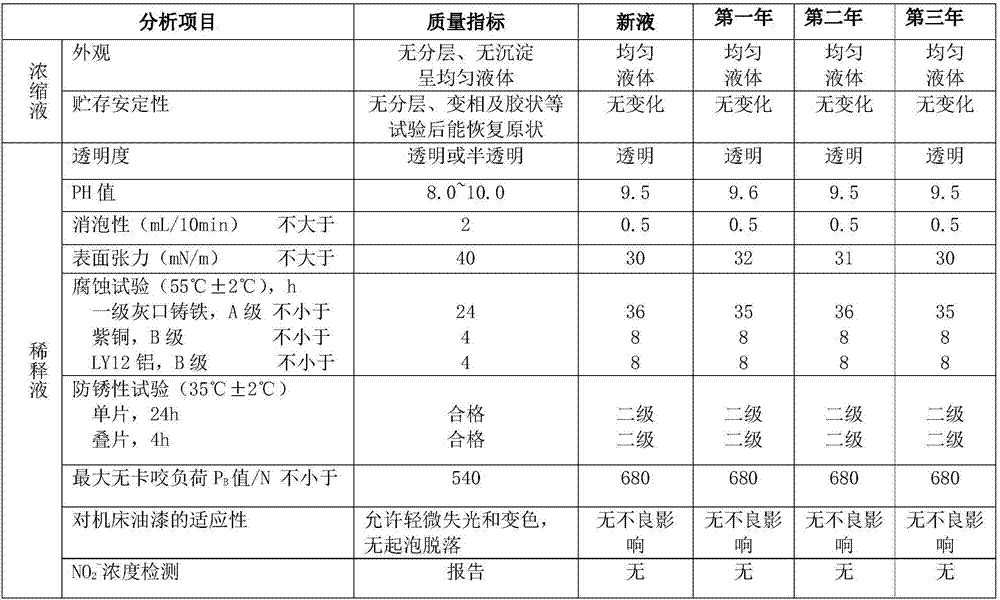

Image

Examples

Embodiment 1

[0025] In the non-emission recyclable water-based cutting fluid of this embodiment, the cutting fluid raw material includes the following components by weight percentage:

[0026] 5% high viscosity water-soluble polyether SDN-20, 0.1% graphene, 25% polyether SDR-40, 2% wetting agent, 1.5% glacial acetic acid, 0.1% complexing agent, 15% antiwear agent, 15% Triethanolamine, 2% German Shumei OK and 34.3% water.

[0027] In this embodiment, the wetting agent is polyethylene glycol 600.

[0028] In this embodiment, the anti-wear agent is alcohol amine borate. In this embodiment, it is preferably alcohol amine borate, and other anti-wear agents that can achieve the same function and effect in this prescription can also be selected. agent.

[0029] In this embodiment, the complexing agent is disodium EDTA. In this embodiment, it is preferably disodium EDTA, and other complexing agents that can achieve the same function and effect in this prescription can also be selected.

Embodiment 2

[0031] In the non-emission recyclable water-based cutting fluid of this embodiment, the cutting fluid raw material includes the following components by weight percentage:

[0032] 14.7% high viscosity water-soluble polyether SDN-20, 10% graphene, 25% polyether SDR-40, 20% wetting agent, 0.2% glacial acetic acid, 0.1% complexing agent, 4% antiwear agent, 5% Triethanolamine, 1% German Shumei OK and 20% water.

[0033] In this embodiment, the wetting agent is polyethylene glycol 600.

[0034] In this embodiment, the anti-wear agent is alcohol amine borate. In this embodiment, it is preferably alcohol amine borate, and other anti-wear agents that can achieve the same function and effect in this prescription can also be selected. agent.

[0035] In this embodiment, the complexing agent is disodium EDTA. In this embodiment, it is preferably disodium EDTA, and other complexing agents that can achieve the same function and effect in this prescription can also be selected.

Embodiment 3

[0037] In the non-emission recyclable water-based cutting fluid of this embodiment, the cutting fluid raw material includes the following components by weight percentage:

[0038] 5% high viscosity water-soluble polyether SDN-20, 10% graphene, 10% polyether SDR-40, 20% wetting agent, 0.2% glacial acetic acid, 10% complexing agent, 4% antiwear agent, 15% Triethanolamine, 1% German Shumei OK and 24.8% water.

[0039] In this embodiment, the wetting agent is polyethylene glycol 600.

[0040] In this embodiment, the anti-wear agent is alcohol amine borate. In this embodiment, it is preferably alcohol amine borate, and other anti-wear agents that can achieve the same function and effect in this prescription can also be selected. agent.

[0041]In this embodiment, the complexing agent is disodium EDTA. In this embodiment, it is preferably disodium EDTA, and other complexing agents that can achieve the same function and effect in this prescription can also be selected.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com