Quick connector working under pressure

A working and fast technology, applied in mechanical equipment, couplings, etc., can solve problems such as unsatisfactory flow channel sealing performance, and achieve the effects of safe and reliable product connection, high anti-rust and corrosion resistance, and high operating temperature range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

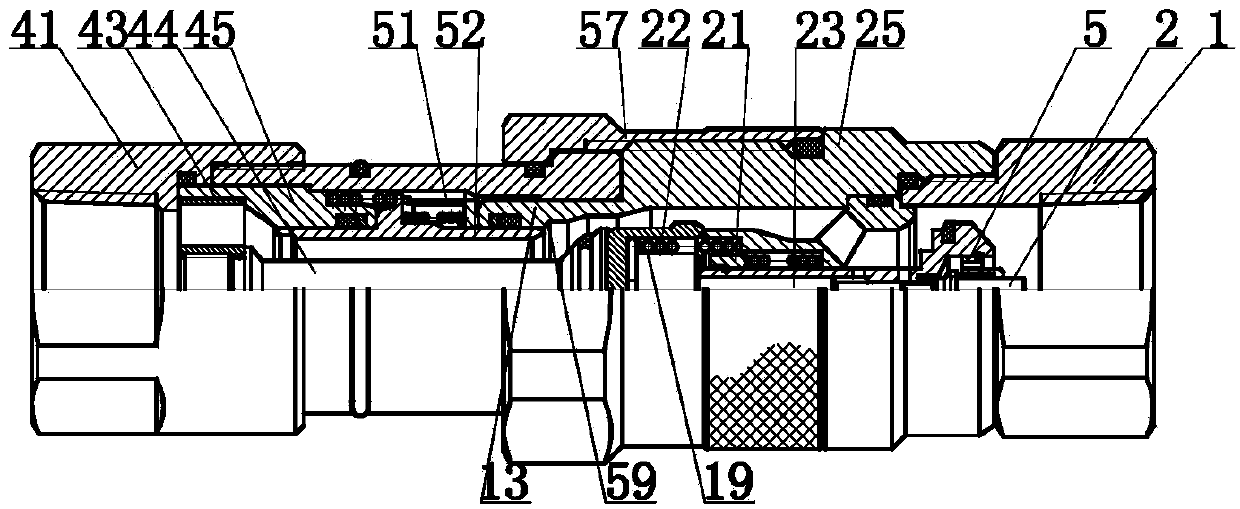

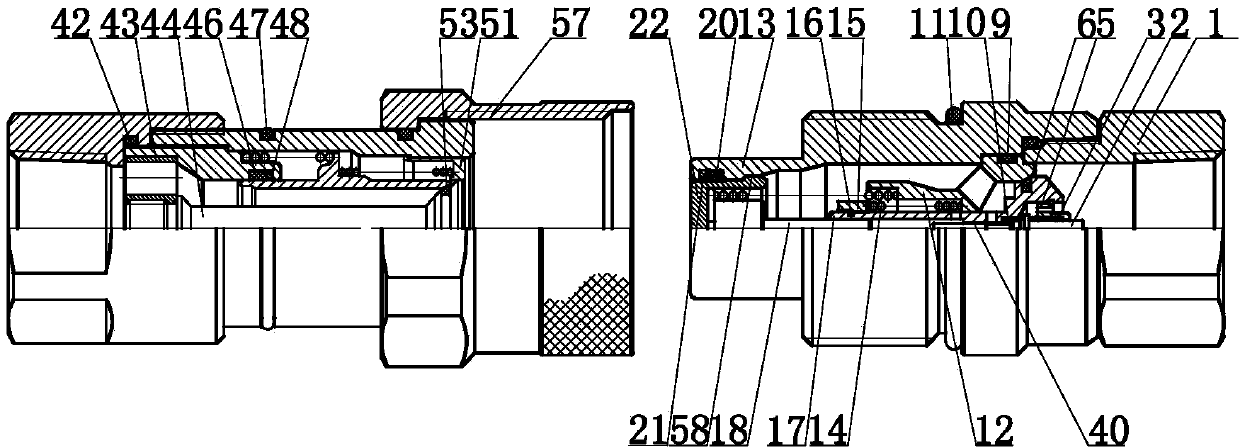

[0013] Such as figure 1 , 2 A quick connector working under pressure is shown, which includes a male connector and a female connector. The male connector includes a plug connector body 1, a plug valve seat 12 and a plug valve core 22. The upper part of the plug valve seat 12 is connected to the plug connector body. 1 The inner wall of the middle part is in contact, the lower part of the plug valve seat 12 is in close contact with the front and rear ends of the plug valve core rod cover 17, and the plug valve core rod A18 is arranged under the plug valve core rod cover 17, and the front end of the plug valve core rod A18 is in contact with the plug The spool 22 contacts, and the rear end is connected to the plug spool rod B40, and the plug spool rod B40 is connected to the plug spool sleeve spool 2, and the rear end of the plug spool rod sleeve 17 is provided with a plug spool sleeve valve seat 5, The connecting block on the plug spool cover spool 2 is close to the plug spool ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com