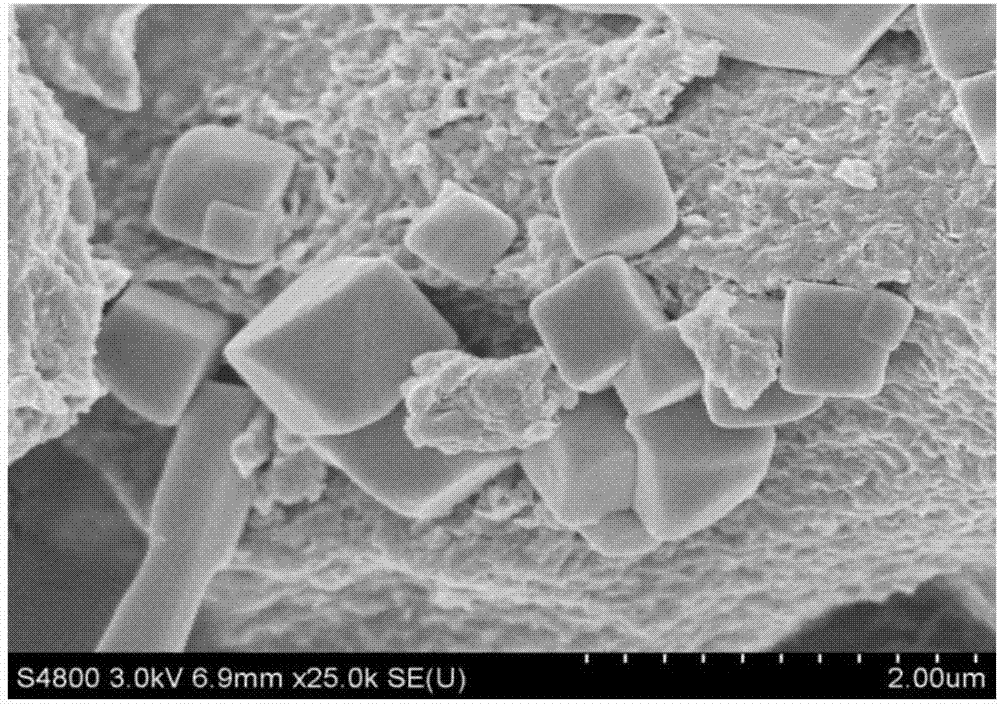

Preparation method of SnS2 sodium-ion battery anode material with cubic structure

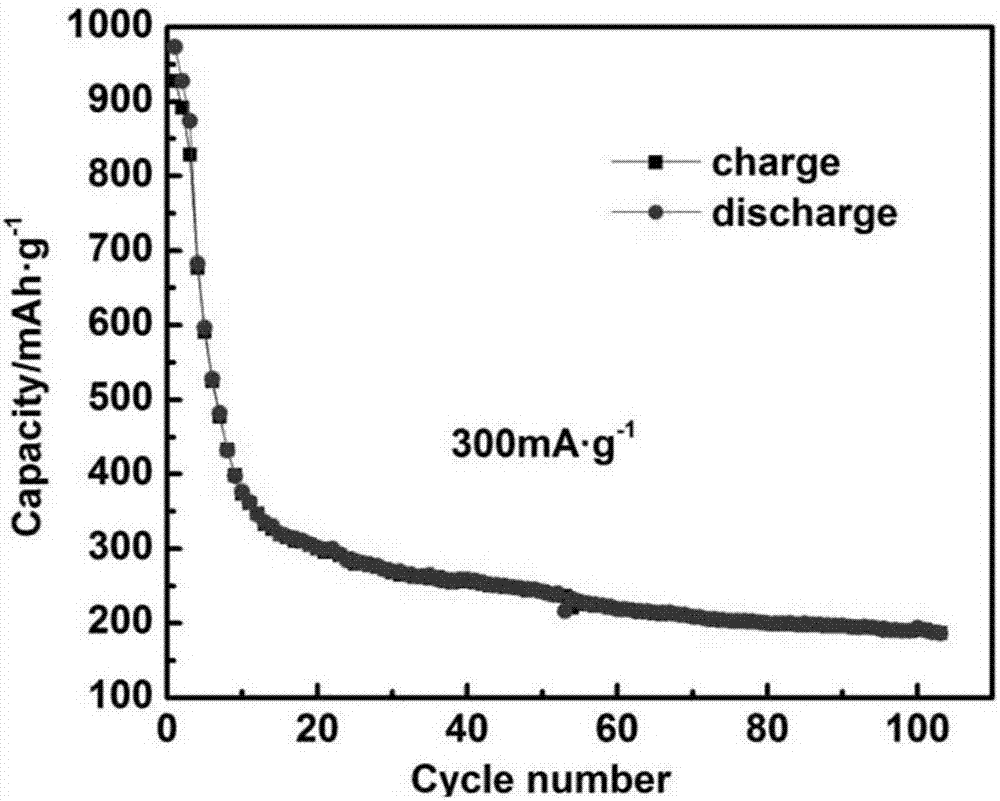

A technology for sodium ion batteries and negative electrode materials, which is applied in battery electrodes, nanotechnology for materials and surface science, secondary batteries, etc., can solve the problems of small yield of nanosheets, incomplete reaction, poor controllability, etc. Excellent charge-discharge rate performance, uniform morphology, and fast rate effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0027] A cubic structure SnS 2 A preparation method for a negative electrode material for a sodium ion battery, comprising the following steps:

[0028] 1) Sodium thiosulfate (Na 2 S 2 o 2 ) was dissolved in deionized water, and prepared into a solution A with a concentration of 0.2 to 1.0 mol / L, according to the molar ratio n of the element substance Sn :n S =1.0: (2.0~4.2) tin chloride pentahydrate (SnCl 4 ·5H 2 O) being dissolved in an equal amount of deionized water (i.e. equal to the deionized water of dissolving sodium thiosulfate) to prepare solution B;

[0029] 2) Add solution B dropwise to solution A under magnetic stirring to obtain mixed solution C, then press n under magnetic stirring 五水氯化锡 :n 十六烷基三甲基氯化铵=1: The ratio of (0.00062~0.01187) gradually adds cetyltrimethylammonium chloride (CTAC) into the mixed solution C to form a uniformly mixed solution D;

[0030] 3) Put the mixed solution D into an ultrasonic generator and ultrasonically vibrate for 1-3 hou...

Embodiment 1

[0036] 1) Sodium thiosulfate (Na 2 S 2 o 2 ) was dissolved in deionized water, and prepared into a solution A with a concentration of 0.2mol / L, according to the molar ratio n of the element substance Sn :n S =1.0:2.0 tin chloride pentahydrate (SnCl 4 ·5H 2 O) be dissolved in equal amount of deionized water and be prepared into solution B;

[0037] 2) Add solution B dropwise to solution A under magnetic stirring to obtain mixed solution C, then press n under magnetic stirring 五水氯化锡 :n 十六烷基三甲基氯化铵 =1:0.00062 ratio cetyltrimethylammonium chloride (CTAC) was gradually added to the mixed solution C to form a uniformly mixed solution D;

[0038] 3) Put the mixed solution D into an ultrasonic generator for ultrasonic oscillation for 1 h.

[0039] 4) Under the action of magnetic stirring, add ammonia water dropwise to the mixed solution D to adjust the pH of the solution to 4 to form a solution E;

[0040] 5) Put the E solution into a hydrothermal reactor and seal it, and cont...

Embodiment 2

[0043] 1) Sodium thiosulfate (Na 2 S 2 o 2 ) was dissolved in deionized water, and prepared into a solution A with a concentration of 0.7mol / L, according to the molar ratio n of the element substance Sn :n S =1.0:3.0 tin chloride pentahydrate (SnCl 4 ·5H 2 O) be dissolved in equal amount of deionized water and be prepared into solution B;

[0044] 2) Add solution B dropwise to solution A under magnetic stirring to obtain mixed solution C, then press n under magnetic stirring 五水氯化锡 :n 十六烷基三甲基氯化铵 =1:0.0086 ratio cetyltrimethylammonium chloride (CTAC) was gradually added to the mixed solution C to form a uniformly mixed solution D;

[0045] 3) Put the mixed solution D into an ultrasonic generator for ultrasonic oscillation for 2 hours.

[0046] 4) Under the action of magnetic stirring, add ammonia water dropwise to the mixed solution D, and adjust the pH of the solution to 5 to form a solution E;

[0047] 5) Put the E solution into a hydrothermal reactor and seal it, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com