Foaming agent composition, preparation method and application thereof, foamed ceramic wallboard powder and preparation method thereof

A foaming ceramic and foaming agent technology, applied in the field of ceramic materials, can solve problems affecting product quality, foaming agent powder agglomeration, foaming agent powder is not easy to disperse, etc., to improve quality and quality, improve dispersion performance, ensure The effect of uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0061] In order to overcome the imperfection of the prior art, the present invention provides a foaming agent composition, a preparation method and application thereof, a foamed ceramic wallboard powder and a preparation method thereof, which can significantly improve the dispersibility and powder performance of the foaming agent, To ensure the uniformity of the blowing agent in the powder, avoid the occurrence of agglomeration of the blowing agent, and improve the quality and quality of the product.

[0062] Therefore, according to the first aspect of the present invention, in at least one embodiment, a foaming agent composition is provided, which is mainly prepared from the following raw materials by mass:

[0063] 90-110 parts of foaming agent, 1-5 parts of polyethyleneimine and / or polyacrylamide, 350-450 parts of water, 100-150 parts of organic solvent and 0.01-1 part of reinforcing agent.

[0064] The foaming agent used in foamed ceramics generally exists in the micron pa...

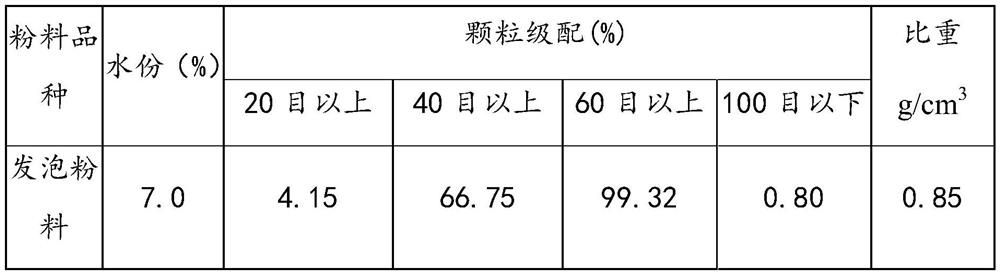

Embodiment 1

[0170] A foaming agent composition is mainly prepared from the following raw materials by mass:

[0171] 95 parts of foaming agent, 6 parts of polyethyleneimine, 360 parts of water, 110 parts of ethylene glycol, 0.08 parts of polyvinyl alcohol and 0.12 parts of modified starch.

Embodiment 2

[0173] A foaming agent composition is mainly prepared from the following raw materials by mass:

[0174] 105 parts of foaming agent, 10 parts of polyethyleneimine, 400 parts of water, 140 parts of ethylene glycol, 0.14 parts of polyvinyl alcohol and 0.18 parts of modified starch.

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of polymerization | aaaaa | aaaaa |

| alcoholysis degree | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com