Method for preparing graphene-based lubricating oil by micro-explosion graphene dispersion

A technology for olefin-based lubricating oil and dispersing graphite, which is applied in the petroleum industry, lubricating compositions, etc., can solve the problems that graphene is difficult to achieve the lubricating effect, the dispersion cannot meet the requirements, etc., and can inhibit the formation of carbon deposits and paint films. , heat resistance and stability, good dispersion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

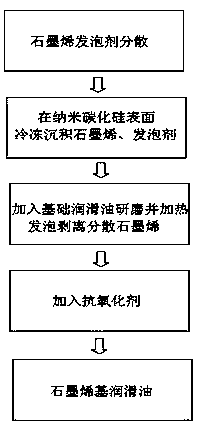

[0047] A kind of method that micro-explosion disperses graphene to prepare graphene-based lubricating oil, comprises the steps:

[0048] Step 1. Graphene with a mass ratio of 3:50:2:3, a mixed solvent (ethanol and deionized water are mixed according to a mass ratio of 30:40), and a dispersant (polyisobutylene polysuccinimide) 1. The foaming agent (ammonium carbonate) is evenly dispersed, and the slurry is ready for use;

[0049] Step 2, ultrasonically dispersing the slurry and nano-silicon carbide in step 1 with a mass ratio of 70:8, and freeze-drying to obtain a dry powder for use;

[0050] Step 3. Stir and disperse the dry powder and base lubricating oil (500N base oil) in step 2 with a mass ratio of 1:80, add antioxidant (2,6-di-tert-butyl-p-cresol) after heating and grinding, and stir evenly. After defoaming treatment, graphene-based lubricating oil is obtained.

[0051] Specifically, the dispersion temperature in the first step is 20° C., the rotational speed is 120 rpm...

Embodiment 2

[0055] A kind of method that micro-explosion disperses graphene to prepare graphene-based lubricating oil, comprises the steps:

[0056] Step 1. Graphene with a mass ratio of 15:200:8:15, mixed solvent (ethanol and deionized water are mixed according to a mass ratio of 60:80), dispersant (polyisobutylene polysuccinimide) 1. The foaming agent (ammonium carbonate) is evenly dispersed, and the slurry is ready for use;

[0057] Step 2, ultrasonically dispersing the slurry and nano-silicon carbide in step 1 with a mass ratio of 120:45, and freeze-drying to obtain a dry powder for use;

[0058] Step 3. Stir and disperse the dry powder and base lubricating oil (500N base oil) in Step 2 with a mass ratio of 5:150, add antioxidant (2,6-di-tert-butyl-p-cresol) after heating and grinding, and stir evenly , defoaming treatment to obtain graphene-based lubricating oil.

[0059] Specifically, the dispersion temperature in the first step is 40°C, the rotational speed is 200 rpm, and the di...

Embodiment 3

[0063] A kind of method that micro-explosion disperses graphene to prepare graphene-based lubricating oil, comprises the steps:

[0064] Step 1. Graphene with a mass ratio of 5:70:3:5, a mixed solvent (ethanol and deionized water are mixed at a mass ratio of 4:55), and a dispersant (polyisobutylene polysuccinimide) 1. The foaming agent (ammonium bicarbonate) is evenly dispersed, and the slurry is ready for use;

[0065] Step 2, ultrasonically dispersing the slurry in step 1 with a mass ratio of 80:10 and nano-silicon carbide, and freeze-drying to obtain a dry powder for use;

[0066] Step 3. Stir and disperse the dry powder and base lubricating oil (500N base oil) in Step 2 with a mass ratio of 2:100, add antioxidant (2,6-di-tert-butyl-p-cresol) after heating and grinding, and stir evenly , defoaming treatment to obtain graphene-based lubricating oil.

[0067] Specifically, the dispersion temperature in the first step is 30° C., the rotational speed is 150 rpm, and the dispe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com