Ultra-short electrospinning polyimide nanofiber and preparing method thereof

A technology of ultra-short polyimide and polyimide fibers, applied in the direction of single-component polyamide rayon, fiber processing, fiber chemical characteristics, etc., can solve the problem of poor length uniformity, insufficient diameter, and small fiber surface area and other problems, to achieve the effect of high degree of orientation, uniform ultra-short length and good dispersion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0024] In order to solve the above technical problems, the present invention provides a preparation method of ultra-short electrospun polyimide nanofibers. The preparation process includes:

[0025] (1) Preparation of polyamic acid solution;

[0026] (2) Electrospinning to form polyamic acid fiber felt;

[0027] (3) Cut the polyamic acid fiber felt into strips;

[0028] (4) Thermal drawing to form polyimide fiber;

[0029] (5) Cut to form ultra-short polyimide nanofibers.

[0030] In one embodiment, the raw materials prepared in the preparation process of the polyamic acid solution include tetraacid dianhydride monomer, diamine monomer, and polar solvent.

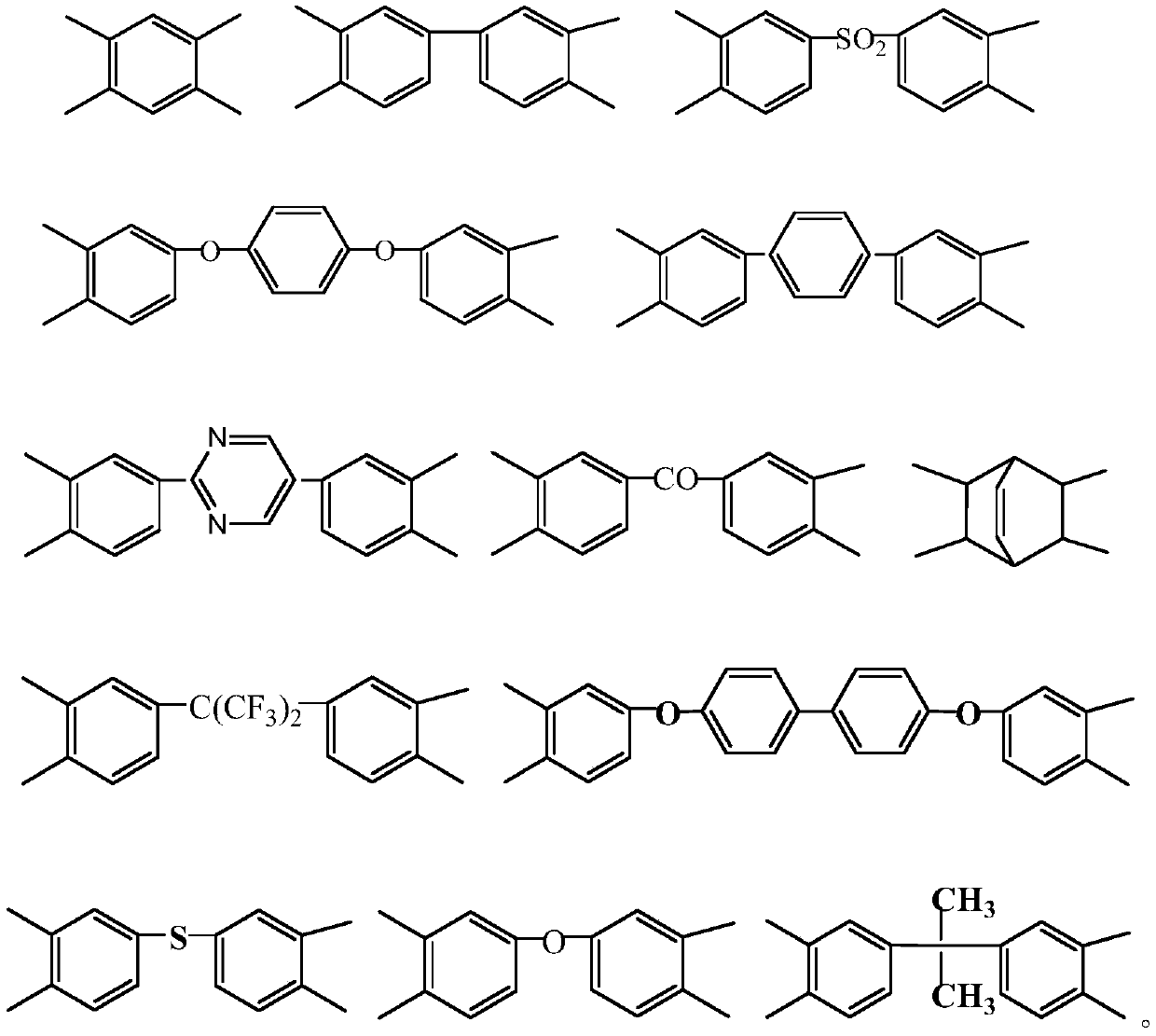

[0031] In one embodiment, the tetraacid dianhydride monomer is Where R 1 It is any one or a combination of the following groups:

[0032]

[0033]

[0034] Preferably, R 1 for

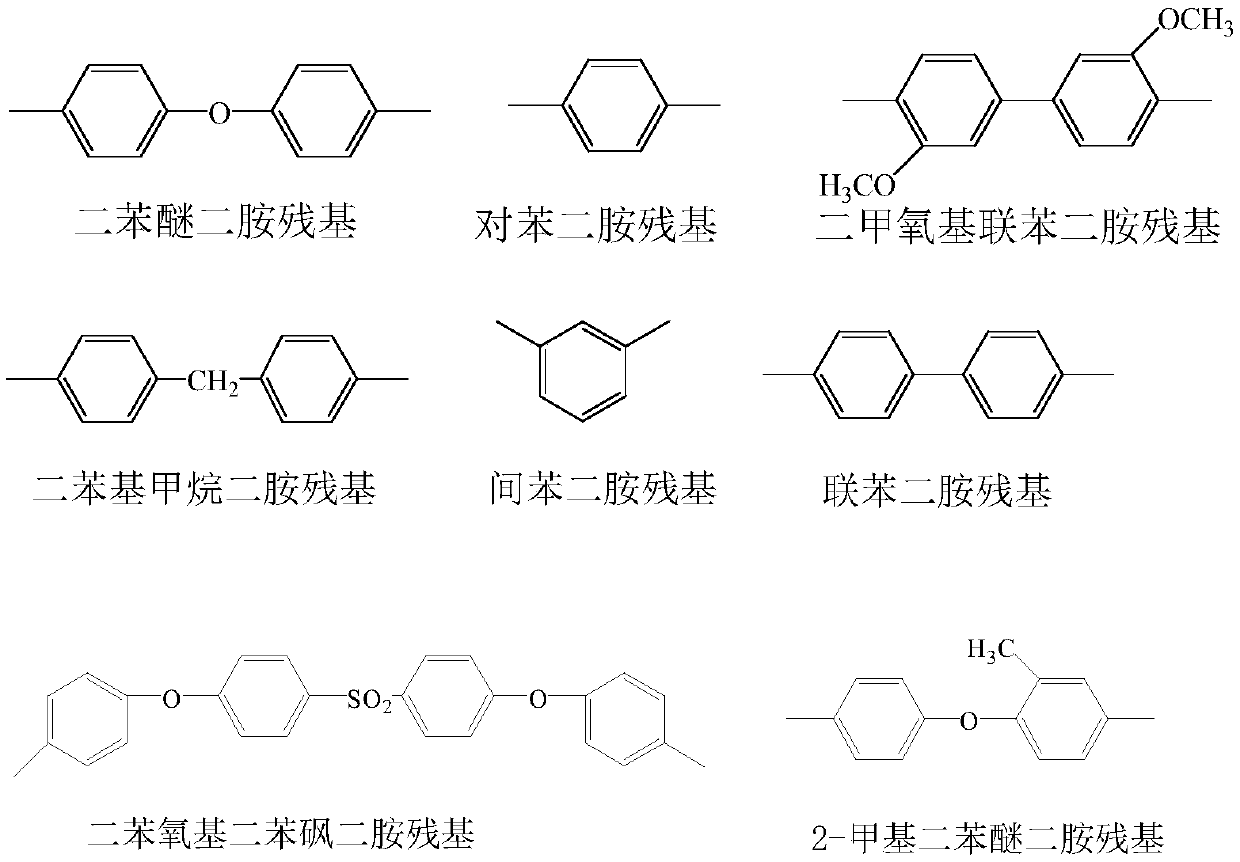

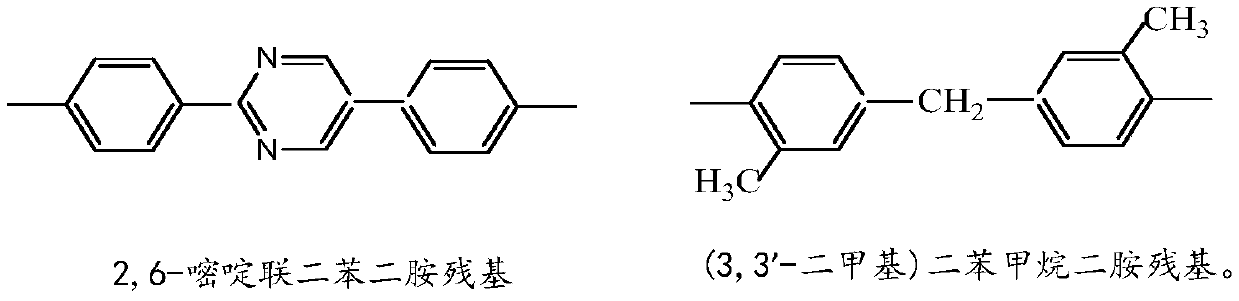

[0035] In one embodiment, the diamine monomer is H 2 N-R 2 -NH 2 , Where R 2 It is any one or a combination of the following groups:

[0036]

[0037] Preferabl...

Embodiment 1

[0060] Embodiment 1 of the present invention provides an ultrashort electrospun polyimide nanofiber, the preparation process of which includes:

[0061] (1) Preparation of polyamic acid solution;

[0062] (2) Electrospinning to form polyamic acid fiber felt;

[0063] (3) Cut the polyamic acid fiber felt into strips;

[0064] (4) Thermal drawing to form polyimide fiber;

[0065] (5) Cut to form ultra-short polyimide nanofibers;

[0066] The raw materials used in the preparation of the polyamic acid solution include tetraacid dianhydride monomer, diamine monomer and polar solvent. The molar ratio of tetraacid dianhydride monomer to diamine monomer is 1:1; tetraacid dianhydride The weight ratio of the total weight of the monomer and the diamine monomer to the polar solvent is 22:100;

[0067] Tetraacid dianhydride monomer is R 1 for

[0068] Diamine monomer is H 2 N-R 2 -NH 2 , R 2 for

[0069] The polar solvent is N,N-dimethylacetamide;

[0070] The preparation method of the polyamic acid ...

Embodiment 2

[0076] Embodiment 2 of the present invention provides an ultrashort electrospun polyimide nanofiber, the preparation process of which includes:

[0077] (1) Preparation of polyamic acid solution;

[0078] (2) Electrospinning to form polyamic acid fiber felt;

[0079] (3) Cut the polyamic acid fiber felt into strips;

[0080] (4) Thermal drawing to form polyimide fiber;

[0081] (5) Cut to form ultra-short polyimide nanofibers;

[0082] The raw materials used in the preparation process of the polyamic acid solution include tetraacid dianhydride monomer, diamine monomer and polar solvent. The molar ratio of tetraacid dianhydride monomer to diamine monomer is 1.2:1; tetraacid dianhydride The weight ratio of the total weight of the monomer and the diamine monomer to the polar solvent is 25:100;

[0083] Tetraacid dianhydride monomer is R 1 for

[0084] Diamine monomer is H 2 N-R 2 -NH 2 , R 2 for

[0085] The polar solvent is N,N-dimethylacetamide;

[0086] The preparation method of the poly...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com