Method for preparing nano Ag/polymer antimicrobial film by utilizing irradiation method

A polymer film and polymer technology, applied in the field of nano-biomaterials, achieves high yield, short preparation cycle and controllable process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

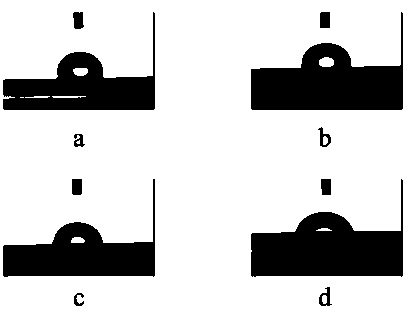

Method used

Image

Examples

Embodiment 1

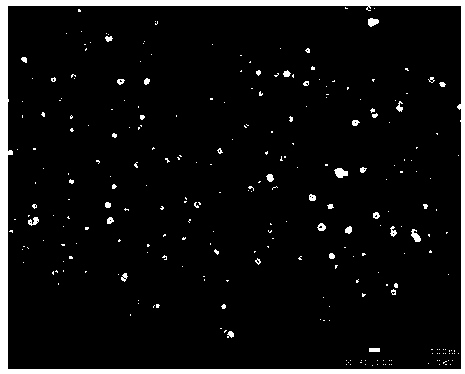

[0039] Take 10ml of NVP monomer, dissolve it in 5ml of ethanol, add 10ml of 0.1mol / L AgNO3 solution, stir the mixed solution evenly, put the PLA film into the mixed solution, vacuumize and fill with nitrogen for 5 times, seal reaction vessel, 60 Co-γ-ray irradiation 5kGy, take out the PLA film, rinse repeatedly with distilled water, and dry it in vacuum at 37°C to obtain light yellow transparent nano-Ag / PLA antibacterial film. The silver content of the antibacterial film is 1.2wt%, and the water absorption rate is 4.3%.

[0040] Tested according to the light industry standard QB / T 2591-2003 of the People's Republic of China, the antibacterial film is 24 hours against Escherichia coli 10 7 The antibacterial rate of CFU / ml is 99.1%.

Embodiment 2

[0042] Take 15ml of NVP monomer, dissolve it in 5ml of ethanol and water solution (the volume ratio of ethanol and water is 1:1), then add 5ml of 0.4mol / L AgNO3 solution, stir the mixed solution evenly, and put the PLGA membrane Put into the mixed solution, vacuumize, fill with nitrogen and operate repeatedly 5 times, seal the reaction vessel, 60 Co-γ-ray irradiation 1kGy, take out the PLGA film, rinse repeatedly with distilled water, and dry it in vacuum at 37°C to obtain a dark yellow transparent nano-Ag / PLGA antibacterial film. The silver content of the antibacterial film is 0.2wt%, and the water absorption rate is 2.0%.

[0043] Tested according to the light industry standard QB / T 2591-2003 of the People's Republic of China, the antibacterial film is 24 hours against Escherichia coli 10 7 The antibacterial rate of CFU / ml was 97.7%.

Embodiment 3

[0045] Take 10ml of NVP monomer, dissolve it in 5ml of ethanol, then add 10ml of 1.0mol / L AgNO3 solution, stir the mixed solution evenly, put the PU film into the mixed solution, vacuumize and fill with nitrogen for 5 times, seal reaction vessel, 60 Co-γ-rays were irradiated to 20kGy, and the PU film was taken out, rinsed repeatedly with distilled water, and vacuum-dried at 37°C to obtain a gray-black nano-Ag / PU antibacterial film. The silver content of the antibacterial film is 10.0wt%, and the water absorption rate is 15%.

[0046] Tested according to the light industry standard QB / T 2591-2003 of the People's Republic of China, the antibacterial film is 24 hours against Escherichia coli 10 7 The antibacterial rate of CFU / ml is 100%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com