Negative electrode material and preparation method thereof, negative electrode and battery

A negative electrode material and negative electrode technology, applied in the field of batteries, can solve the problems of hindering the application of silicon-based negative electrode materials, destroying the stability of electrode structure, and the negative electrode material needs to be improved, so as to improve electrochemical performance, facilitate uniform dispersion, and achieve stable structure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

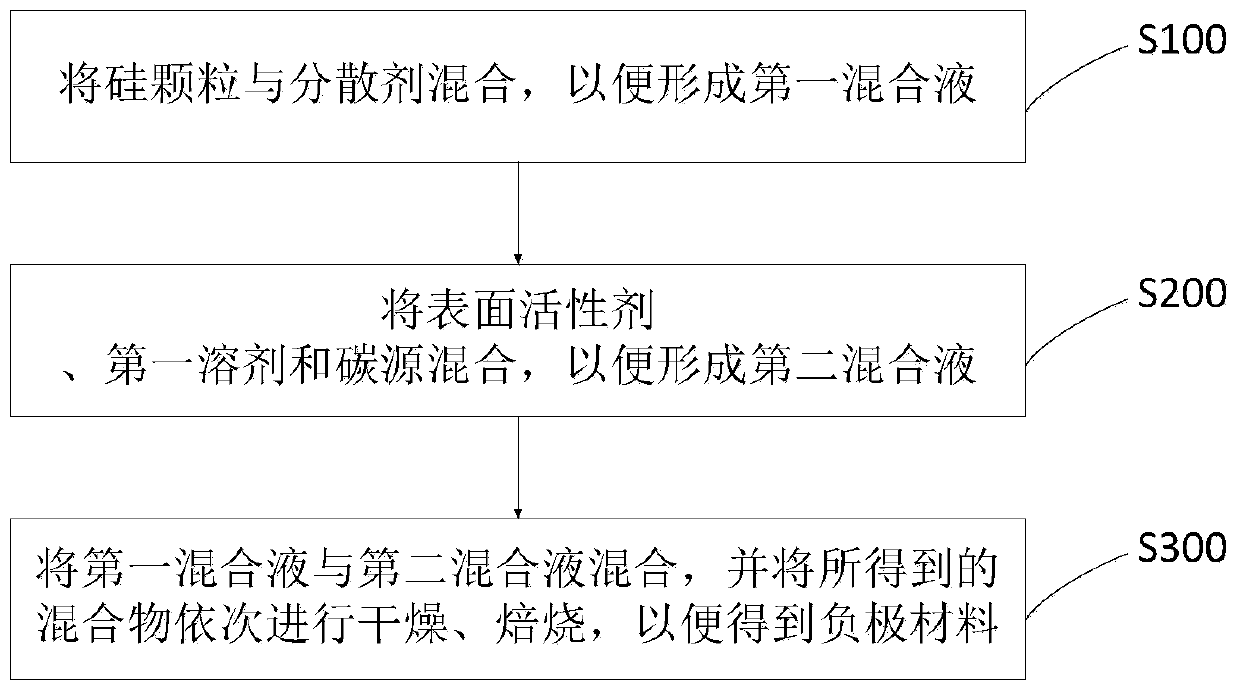

[0068] Preparation of negative electrode material:

[0069] (1) Dissolve 1 g of silicon particles (100 nm) in 10 ml of absolute ethanol, and disperse ultrasonically for 2 hours to form solution A;

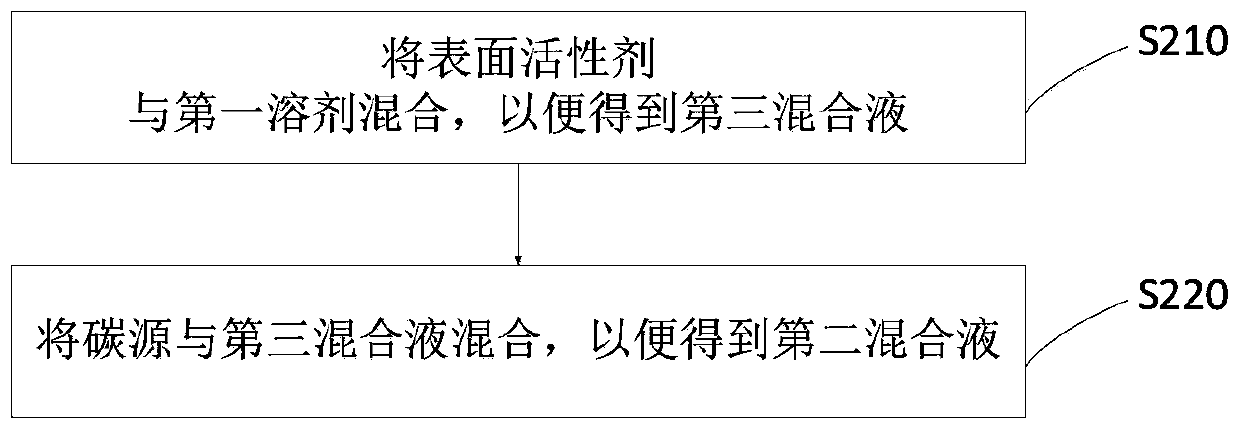

[0070] (2) Weigh 0.04g F127, 0.4g CMC, dissolve in 50ml deionized water, and ultrasonically dissolve for 1h to form solution B;

[0071] (3) Take 4g of graphite, slowly add it to solution B under stirring condition and stir for 3h to form solution C;

[0072] (4) Under stirring conditions, solution A was added dropwise to solution C at a rate of 0.01ml / s, and after the addition was completed, stirring was continued for 2 hours to form solution D;

[0073] (5) Put the solution D in a 70°C water bath, stir and evaporate to dryness, and then heat it up to 800°C for 4 hours under a nitrogen atmosphere at a rate of 5°C / min.

[0074] In this embodiment, the scanning electron microscope image of the negative electrode material can refer to image 3 , the first effect of the lithium-ion...

Embodiment 2

[0076] Preparation of negative electrode material:

[0077] (1) Dissolve 0.5g of silicon particles (150nm) in 10ml of absolute ethanol, ultrasonically disperse for 3 hours to form solution A;

[0078] (2) Dissolve 0.09g P123 and 0.9g PAA in 50ml deionized water, and ultrasonically dissolve for 2 hours to form solution B;

[0079] (3) Take 4.5g graphene, slowly add it into solution B under stirring condition and stir for 2h to form solution C;

[0080] (4) Under stirring conditions, solution A was added dropwise to solution C at a rate of 0.01ml / s, and after the addition was completed, stirring was continued for 2 hours to form solution D;

[0081] (5) Put the solution D in a 70°C water bath, stir and evaporate to dryness, and then roast at 2°C / min to 900°C for 2 hours under a nitrogen atmosphere.

[0082] In this embodiment, the scanning electron microscope image of the negative electrode material can refer to Figure 4 , the first effect of the lithium-ion battery is 89%, ...

Embodiment 3

[0084] Preparation of negative electrode material:

[0085] (1) Dissolve 3g of silicon particles (150nm) in 20ml of absolute ethanol, and disperse ultrasonically for 3h to form solution A;

[0086] (2) Dissolve 0.07g F127 and 0.07g CMC in 85ml of deionized water, and ultrasonically dissolve for 2 hours to form solution B;

[0087] (3) Weigh 7g graphene, slowly add it to solution B under stirring condition and stir for 2h to form solution C;

[0088] (4) Under stirring conditions, solution A is added dropwise in solution C, and the dropping speed is 0.005ml / s, after dropping, continue to stir for 2h to form solution D;

[0089] (5) Put the solution D in a 70°C water bath, stir and evaporate to dryness, and then roast at 2°C / min to 900°C for 2 hours under a nitrogen atmosphere.

[0090] In this embodiment, the scanning electron microscope picture of the negative electrode material is shown in Figure 5 and Figure 6 , the first effect of the lithium-ion battery is 90%, the d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Discharge specific capacity | aaaaa | aaaaa |

| Discharge specific capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com