Rare-earth oxide and microencapsulated red phosphorus synergic flame retardance PA6 composite and preparation method thereof

A technology of microencapsulated red phosphorus and rare earth oxide, which is applied in the field of rare earth oxide and microencapsulated red phosphorus synergistic flame-retardant PA6 composite material and its preparation, which can solve the problem of insufficient density and continuity, sparse carbon layer, red phosphorus flame-retardant polymer Problems such as high calorific value and smoke generation of the material can be achieved to improve the density and continuity, reduce the amount of heat and flammable gas, and improve the effect of condensed phase flame retardancy

Active Publication Date: 2017-05-31

NINGBO INST OF TECH ZHEJIANG UNIV ZHEJIANG

View PDF11 Cites 7 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0005] However, the charcoal layer formed during the flame retardant process of microencapsulated red phosphorus is relatively sparse, not dense and continuous, which leads to a large amount of heat and smoke generation during the combustion process of red phosphorus flame retardant polymer materials.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment

[0029] Example: The experimental materials used in this example can be easily obtained from commercial companies unless otherwise specified.

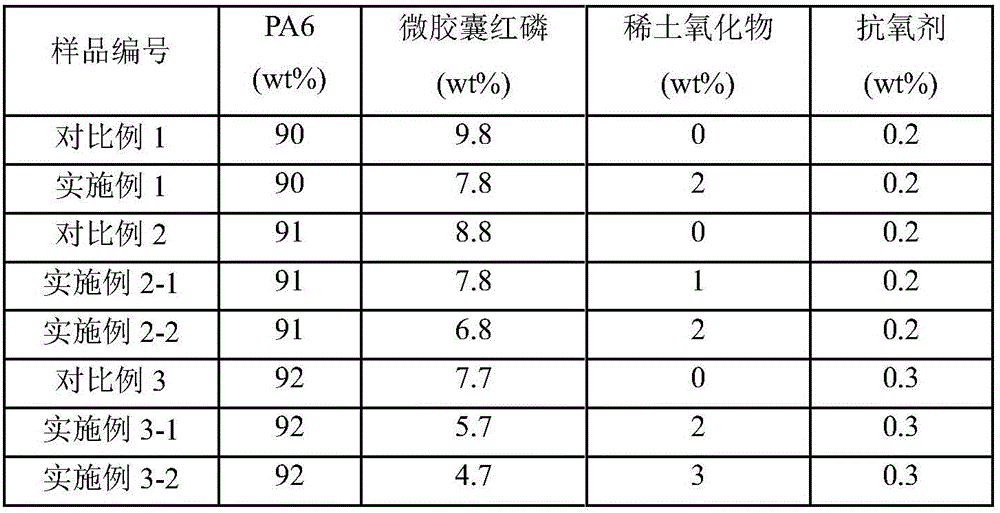

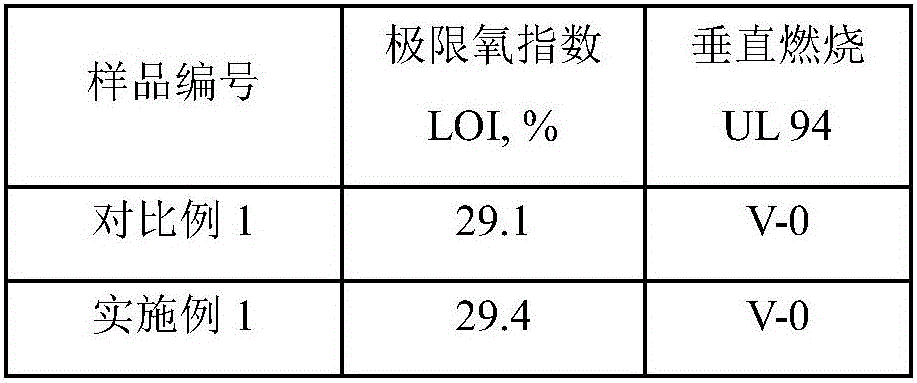

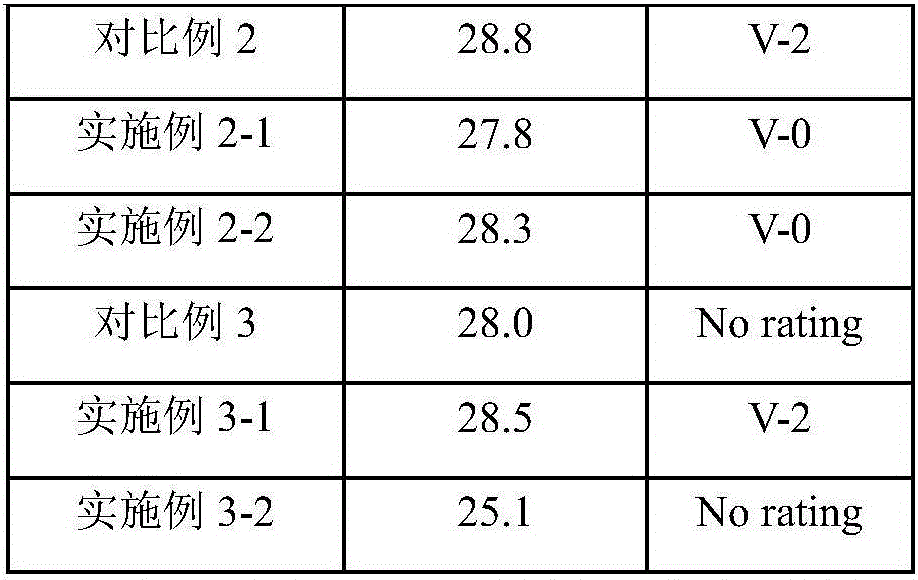

[0030] Formulation and sample number of the embodiment of the present invention and comparative example of table 1

[0031]

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention provides a rare-earth oxide and microencapsulated red phosphorus synergic flame retardance PA6 composite and a preparation method thereof. The rare-earth oxide and microencapsulated red phosphorus synergic flame retardance PA6 composite is characterized by being prepared from PA6, microencapsulated red phosphorus and rare-earth oxide. Rare-earth oxide is introduced into a red phosphorus flame-resistant polymer material system, rare-earth oxide can catalyze dehydrated carbonization of red phosphorus, a more compact and continuous charcoal layer structure can be formed, the mass transfer process of volatile products generated by polymer degradation to a gas phase is blocked, feedback of heat generated by gas phase combustion to a condensed phase is also blocked, and flames are prevented from propagating and spreading.

Description

technical field [0001] The invention relates to the technical fields of organic synthesis, blending of polymer composite materials, and testing of flame-retardant properties of materials, in particular to a flame-retardant PA6 (nylon 6) composite material synergistically formed by rare earth oxide and microcapsule red phosphorus and a preparation method thereof. Background technique [0002] Red phosphorus is a highly active flame retardant with high flame retardant efficiency, and has excellent flame retardant effect on PA, PC, PET and other polymers containing oxygen or nitrogen. However, red phosphorus is easy to absorb moisture in the air, and the red phosphorus existing on the surface of polymer material products absorbs moisture and oxidizes after a period of time, causing the surface of the product to be corroded and lose its luster and original performance, and gradually deepen inward; Red phosphorus has poor compatibility with polymers, and it is not easy to dispers...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C08L77/02C08K13/04C08K9/10C08K3/02C08K3/22C08K7/14

CPCC08K3/02C08K3/22C08K7/14C08K9/10C08K13/04C08K2003/026C08K2003/2213C08K2201/003C08K2201/014C08L2201/02C08L77/02

Inventor 郭正虹方征平蔡远征

Owner NINGBO INST OF TECH ZHEJIANG UNIV ZHEJIANG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com