Preparation method of hydrophilic polyethersulfone microfiltration membrane

A manufacturing method and hydrophilic technology, which are applied in chemical instruments and methods, membrane technology, semi-permeable membrane separation, etc., can solve the problems of membrane damage, harsh conditions of polyethersulfone sulfonation reaction, difficult to carry out stably, etc. cumbersome effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

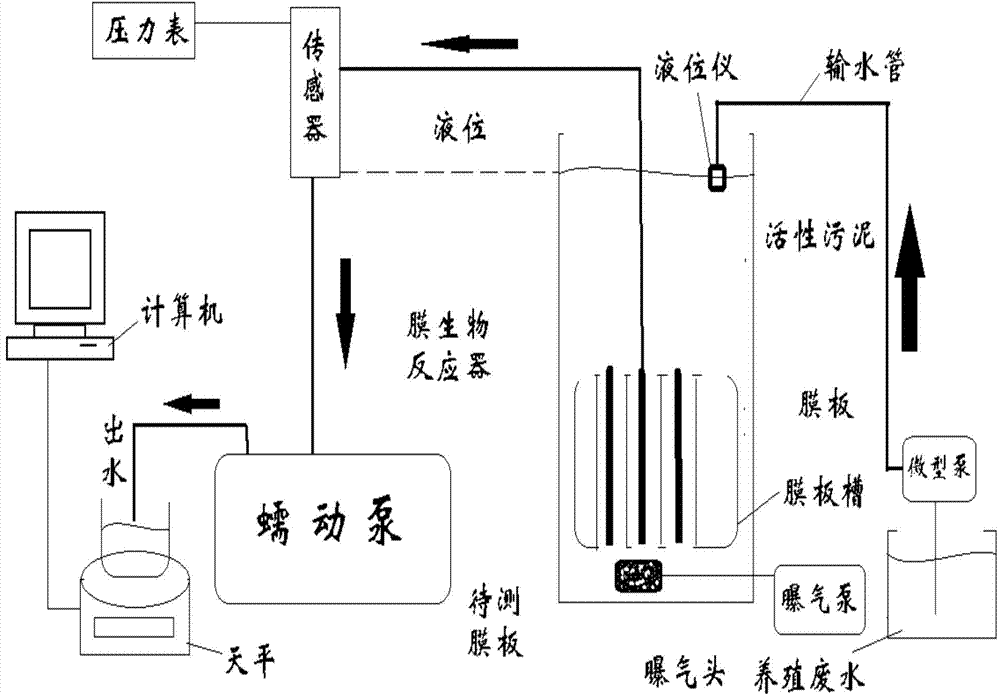

Method used

Image

Examples

Embodiment

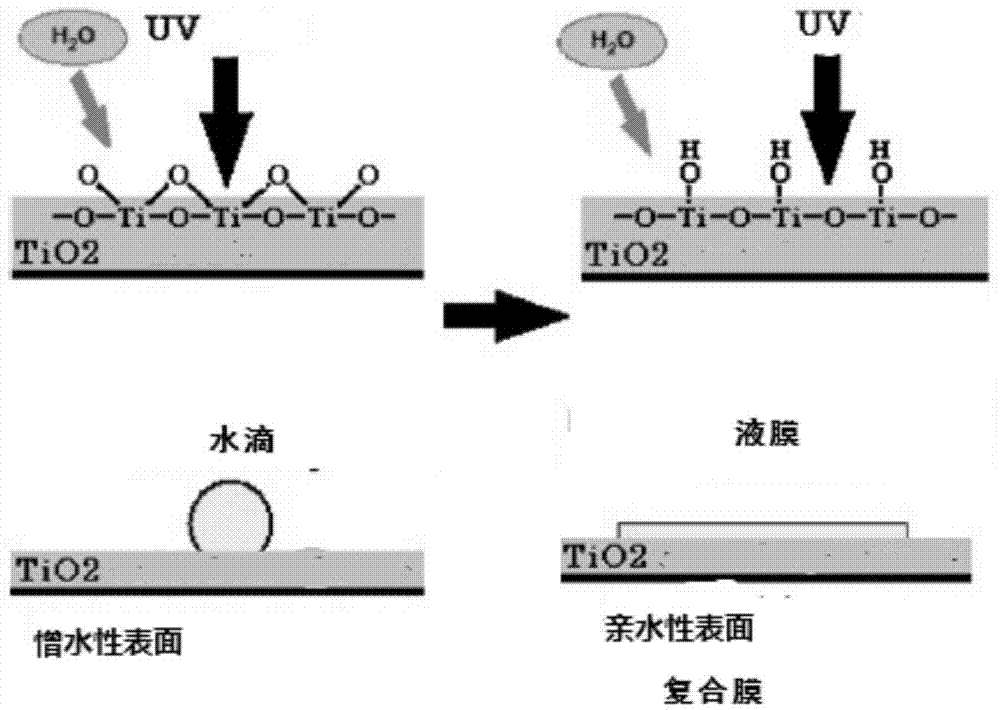

[0041] Dissolve 9-20% of the total mass of polyethersulfone in 20-70% of N,N-dimethylacetamide, add 5-60% of the total mass of polyethylene glycol (molecular mass 400- 20000), 1-10% alkylbenzenesulfonate and 5-50% polyvinylpyrrolidone, stir and dissolve, add 0.1-15% nano-TiO with a particle size of 10-200nm to the above solution 2 , Stir vigorously to obtain the casting solution; scrape the casting solution on the non-woven fabric at room temperature to form a 0.2-0.3mm liquid film, evaporate for 1-5min, immerse in the aqueous solution coagulation bath for phase inversion, and form a film, that is, get Nano TiO2 composite polyethersulfone membrane.

[0042] Table 1 is each material proportioning (wt%) in the embodiment:

[0043] .

[0044] Note: what embodiment 4 adds is nanometer SiO2, embodiment 5 adds nanometer ZrO2.

[0045] Table two is the process parameter of each embodiment:

[0046] .

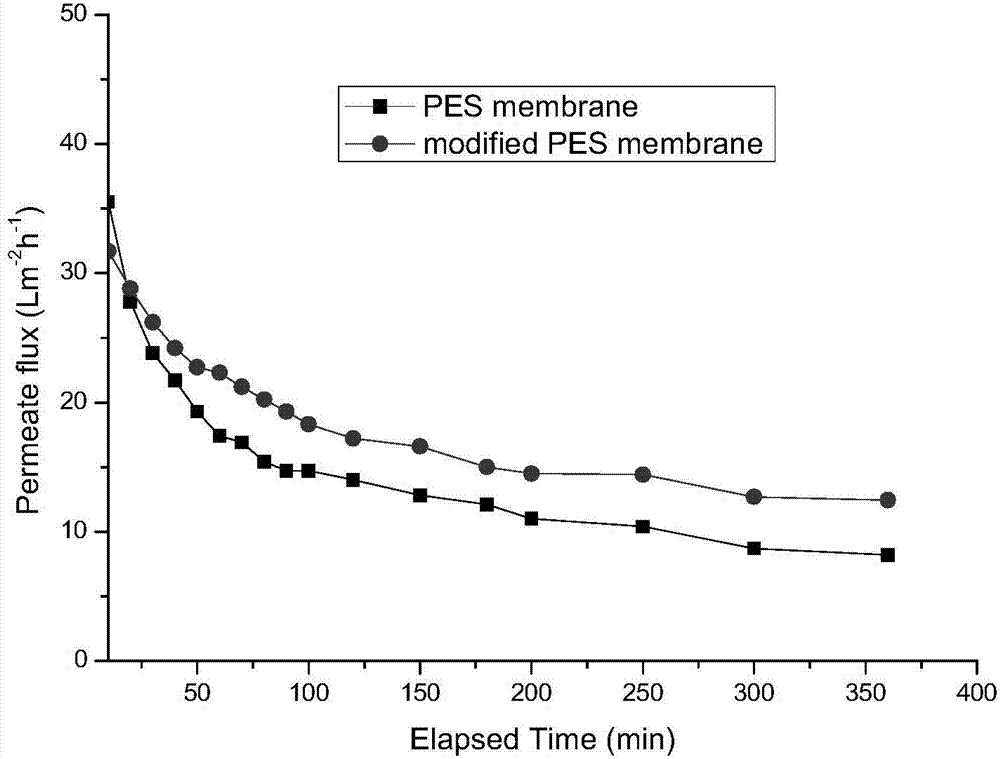

[0047]Table 3 shows the parameters and specifications of the finished pol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com