Sea urchin shaped copper oxide catalyst, as well as preparation method and application thereof

A technology of copper oxide and catalyst, which is applied in the field of direct synthesis of organosilicon monomers, can solve the problems of unfavorable large-scale production and high synthesis cost, and achieve the effects of industrial synthesis, simple operation, and high specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

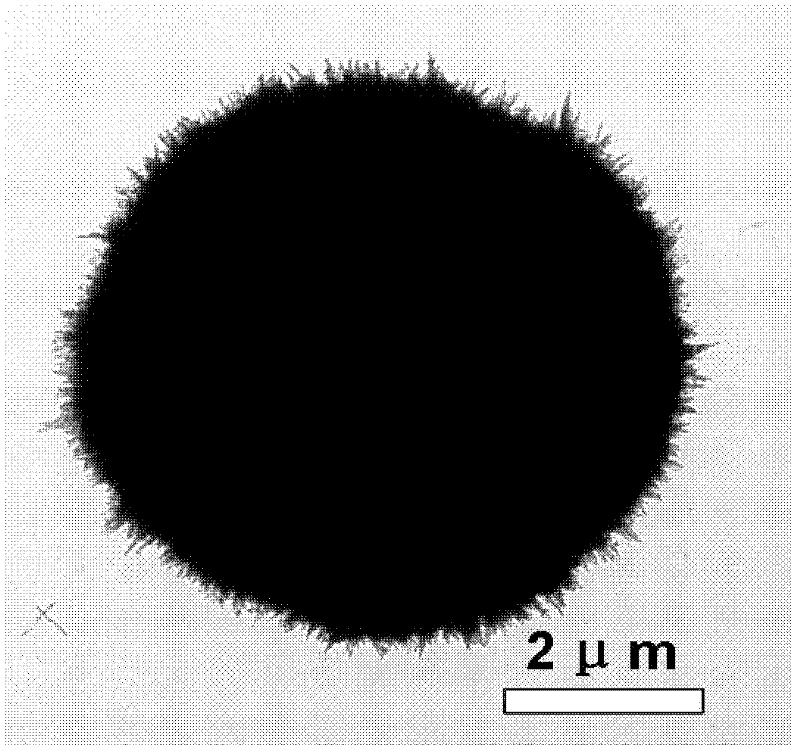

[0049] Weigh 1.0gCu(NO 3 ) 2 ·3H 2 O was dissolved in a mixed solvent formed by 40.0ml of absolute ethanol and 10.0ml of ethylene glycol (the concentration of copper ions was 0.08mol / L), and 30.0ml of concentrated ammonia (commercially available mass fraction was 25-28wt%) was added successively at room temperature , 10.0ml NaOH solution (concentration is 1mol / L), after stirring for 10 minutes, a clear and transparent blue solution (concentration of ammonia is 4.9mol / L, concentration of NaOH is 0.1mol / L), and then transferred to 100ml lined with polytetrafluoroethylene In a stainless steel reaction kettle of ethylene, the temperature was raised to 130° C. for 16 hours. After the reaction, the black product was filtered, washed five times with water and absolute ethanol, and dried in a vacuum oven at 60° C. for 8 hours to obtain 0.30 g of regular sea urchin-shaped copper oxide catalyst with a yield of 91.0 wt%.

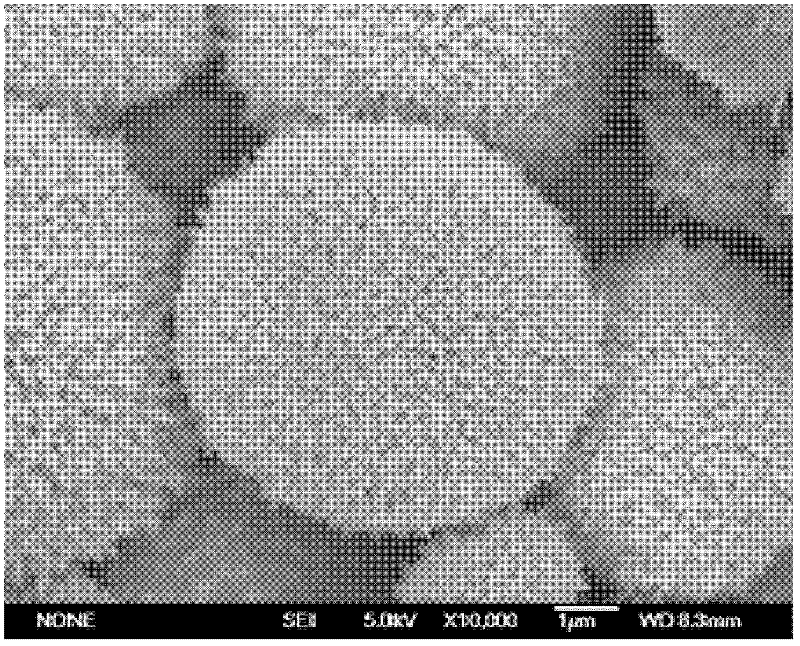

[0050] The surface morphology of the sea urchin-like copper ox...

Embodiment 2

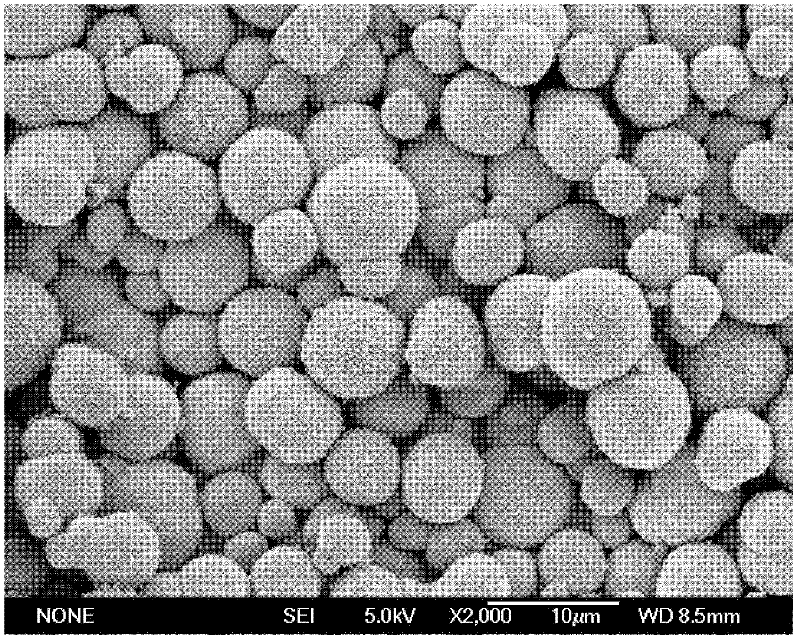

[0054] Weigh 0.6gCu(NO 3 ) 2 ·3H 2 O was dissolved in a mixed solvent formed by 20.0ml of absolute ethanol and 30.0ml of ethylene glycol (the concentration of copper ions was 0.05mol / L), and 25.0ml of concentrated ammonia (commercially available mass fraction was 25-28wt%) was added successively at room temperature , 5.0ml NaOH solution (concentration is 1mol / L), after stirring for 10 minutes, a clear and transparent blue solution (concentration of ammonia is 4.6mol / L, concentration of NaOH is 0.1mol / L), and then transferred to 100ml lined polytetrafluoroethylene In a stainless steel reactor made of ethylene, the temperature was raised to 150° C. for 10 h. After the reaction, the black product was filtered, washed five times with water and absolute ethanol, and dried in a vacuum oven at 60° C. for 8 hours to obtain 0.19 g of copper oxide catalyst with a yield of 96.0 wt%. XRD spectrum analysis shows that the crystal structure of the product is cubic CuO, and the SEM photo s...

Embodiment 3

[0056] Weigh 2.0gCu(NO 3 ) 2 ·3H 2O was dissolved in a mixed solvent formed by 30.0ml absolute ethanol and 20.0ml ethylene glycol (copper ion concentration was 0.16mol / L), and 35.0ml concentrated ammonia water (commercially available mass fraction was 25-28wt%) was added successively at room temperature , 15.0ml NaOH solution (concentration is 1mol / L), after stirring for 10 minutes, a clear and transparent blue solution (concentration of ammonia is 5.2mol / L, concentration of NaOH is 0.2mol / L), and then transferred to 150ml lined with polytetrafluoroethylene In a stainless steel reaction kettle of ethylene, the temperature was raised to 140° C. for 15 hours. After the reaction, the black product was filtered, washed five times with water and absolute ethanol, and dried in a vacuum oven at 60° C. for 8 hours to obtain 0.62 g of copper oxide catalyst with a yield of 93.9 wt%. XRD spectrum analysis shows that the crystal structure of the product is cubic CuO, and SEM photos sho...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com