Kitchen garbage disposer capable of realizing two-stage crushing

A kitchen waste and processor technology, which is applied in grain processing, indoor sanitary piping devices, water supply devices, etc., to achieve the effects of improving utilization, improving crushing efficiency, and refining garbage particles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with the accompanying drawings, but the protection scope of the present invention is not limited to the following description.

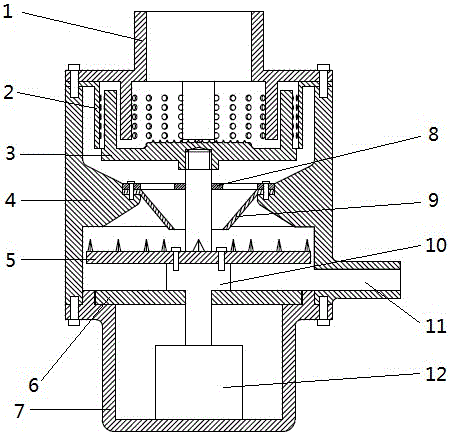

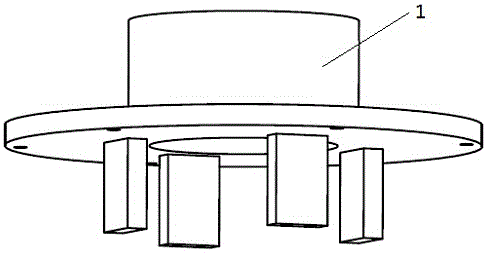

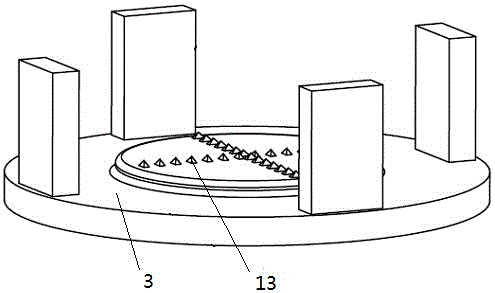

[0027] Such as figure 1 As shown, a two-stage crushing kitchen garbage disposer includes an end cover 1 , an upper chamber 4 , a lower chamber 7 , a crushing cutterhead 3 , and a tapered cutterhead 5 . The end cover 1 and the upper cavity 4, the upper cavity 4 and the lower cavity 7 are connected with each other by screws. The knives cooperate with each other and are placed inside the screen cylinder 2. The upper end of the transmission shaft 10 is threadedly connected with the crushing cutter head 3, and the lower end passes through the round tray 6 to connect with the motor 12 in the lower chamber 7. The support plate 8 and the funnel 9 fit together , fixed in the middle of the upper cavity 4 by screws, the tapered cutter head 5 is fixed on the large cylindrical platform o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com