Inner layer roller with auxiliary scattering grids

A technology of breaking up and meshing, which is used in the preliminary treatment of promoting the drying of solid materials, drying of solid materials, dryers, etc. It can solve the problems of no auxiliary function for crushing, the threat of breaking shaft, and no lifting material.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

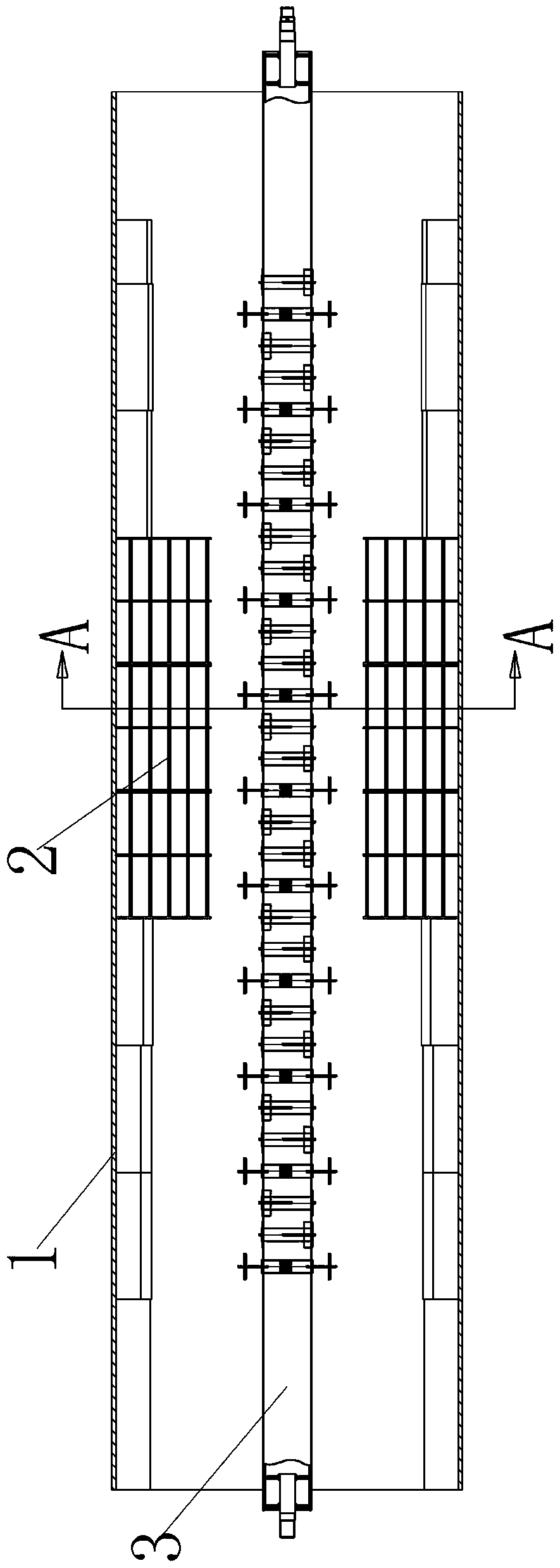

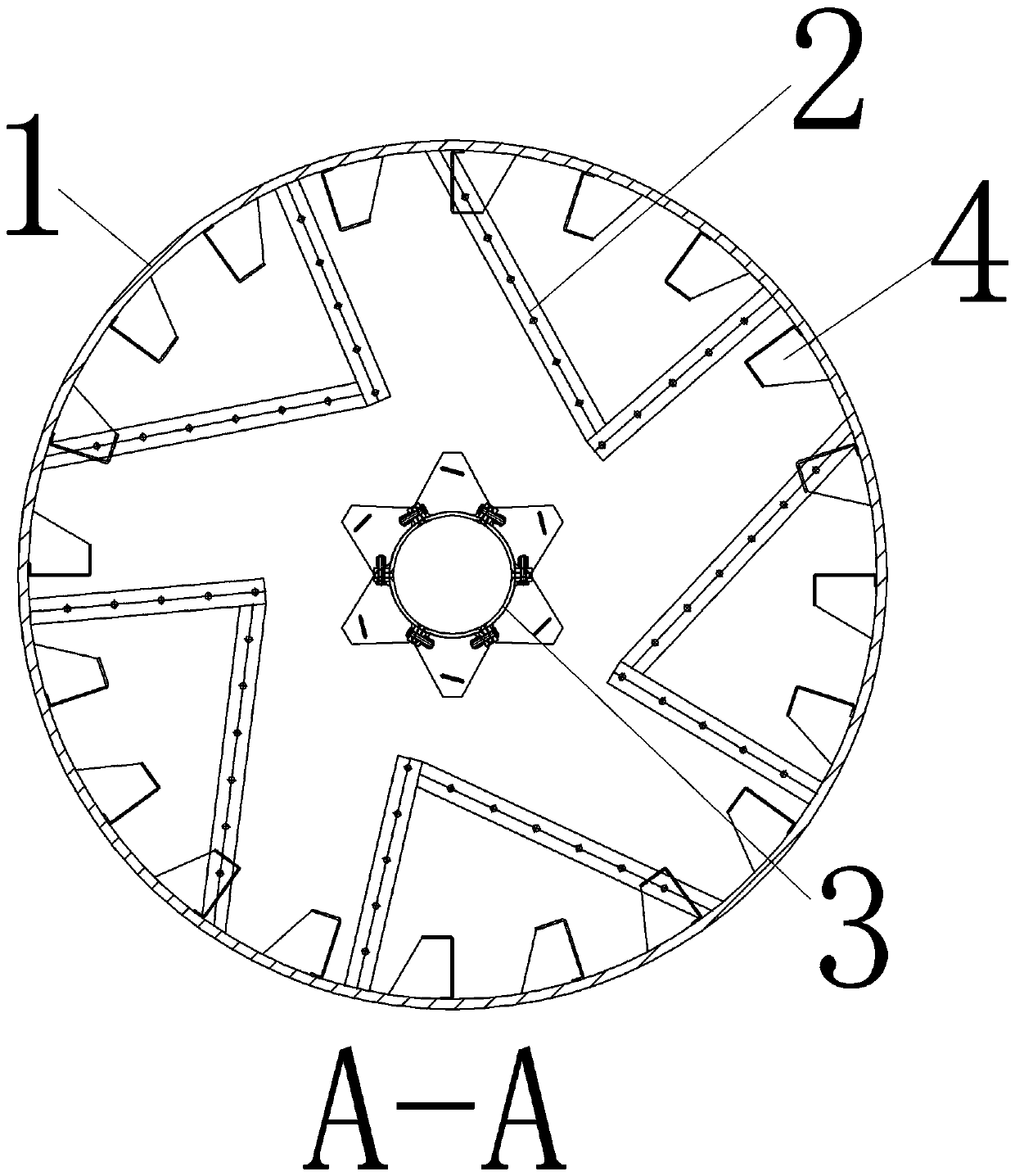

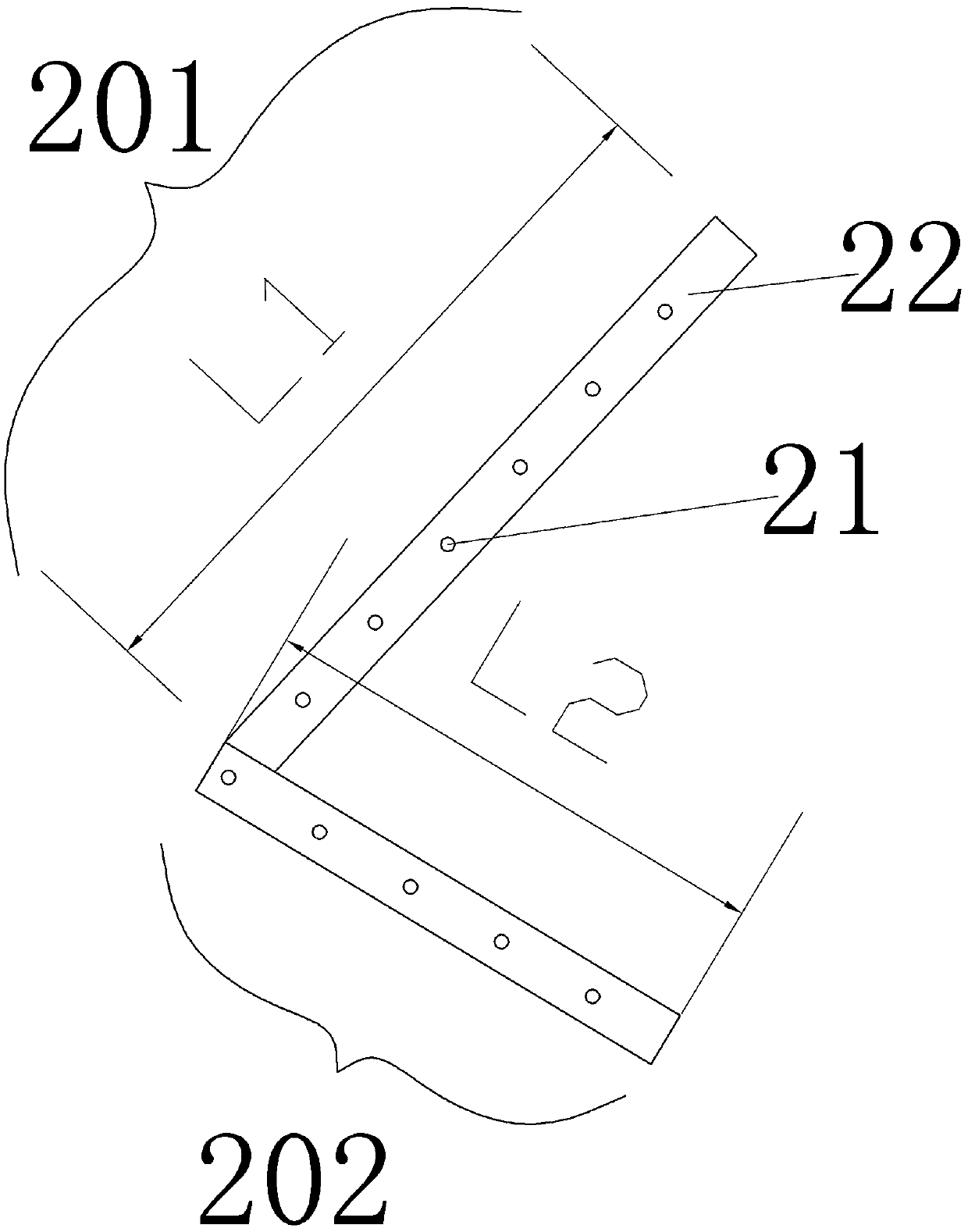

[0017] Embodiment one: see Figure 1-4 , an inner drum with auxiliary dispersing grids in the figure, including a cylinder body, a lifting plate and a material guide plate inside the cylinder body, and several auxiliary punches protruding toward the center of the cylinder body are provided in the middle section of the cylinder body. Scattered grid; the auxiliary scatter grid includes two square grid plates; the bottom edges of the two grid plates are respectively connected to the inner wall of the cylinder, and the upper edges of the two grid plates are connected together ; The cross-section of the auxiliary broken mesh is triangular.

[0018] The two grid panels have the same length; one of the grid panels is a wide grid panel with a width of L1; the other grid panel is a narrow grid panel with a width of L2; L1 / L2=1.5-2.5.

[0019] The arrangement direction of the lower edges of the two grid plates is consistent with the generatrix direction of the inner wall of the cylin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com