Three-level drum type wet material drying machine

A dryer and drum-type technology, which is applied in the field of three-stage drum-type sticky and wet material dryers, can solve the problems of inconvenient maintenance and replacement, wear and tear, and lack of functions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

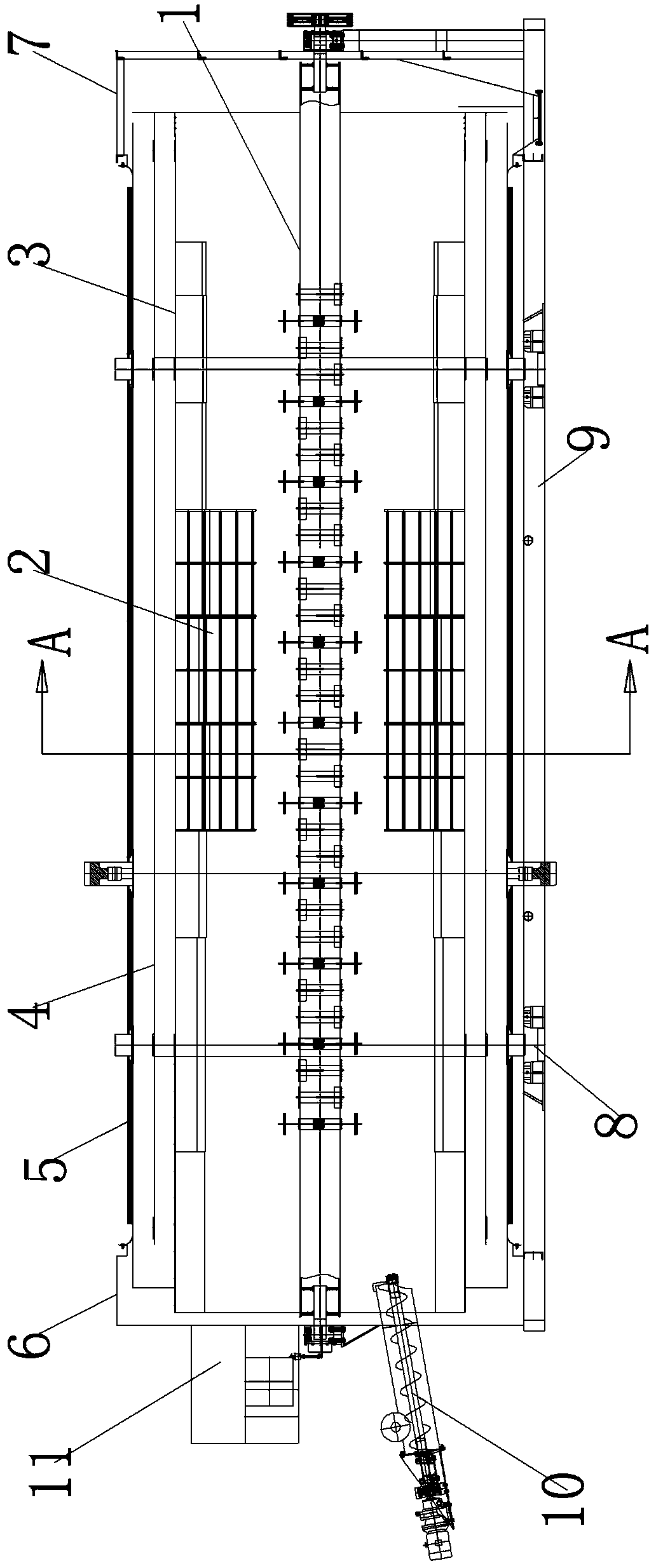

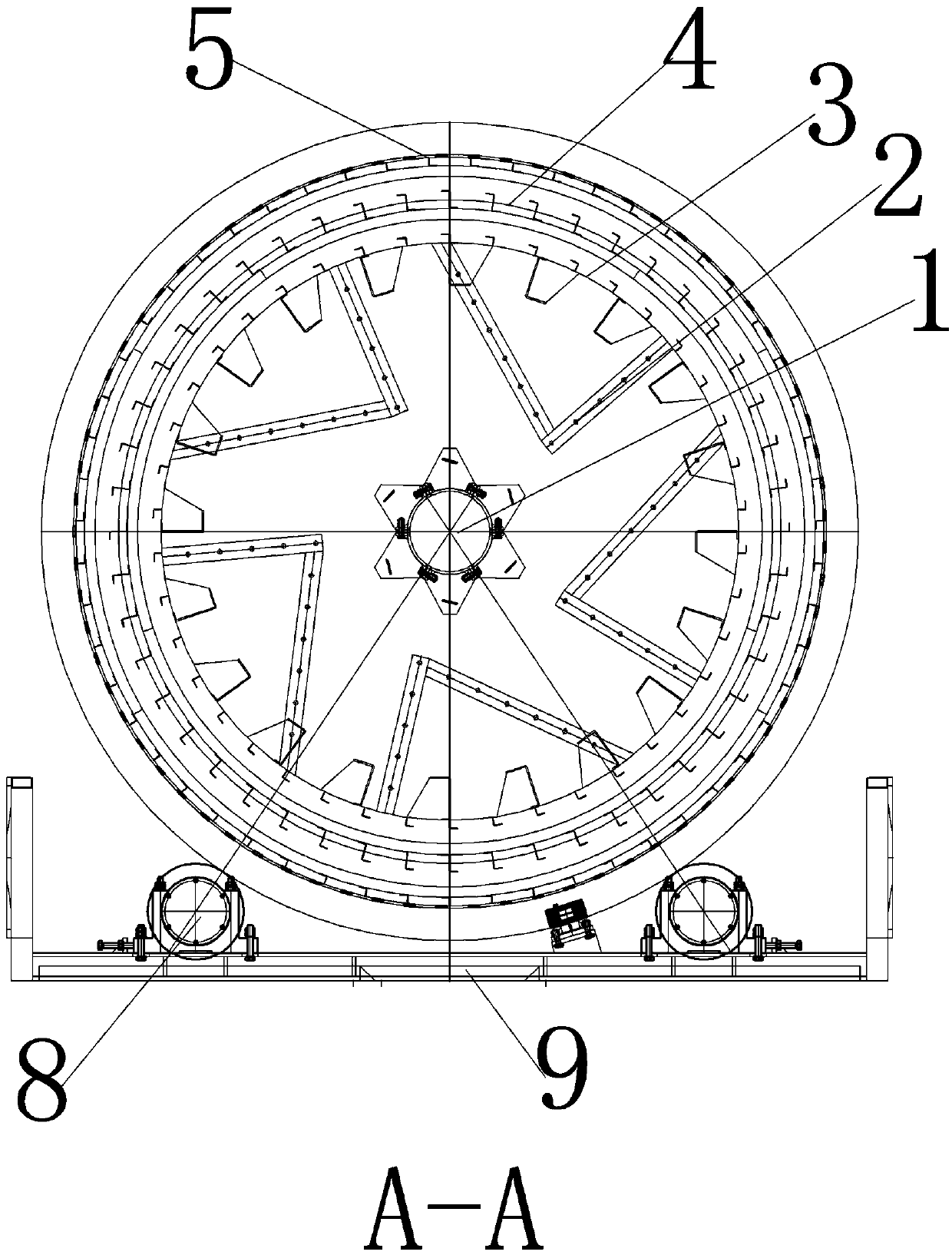

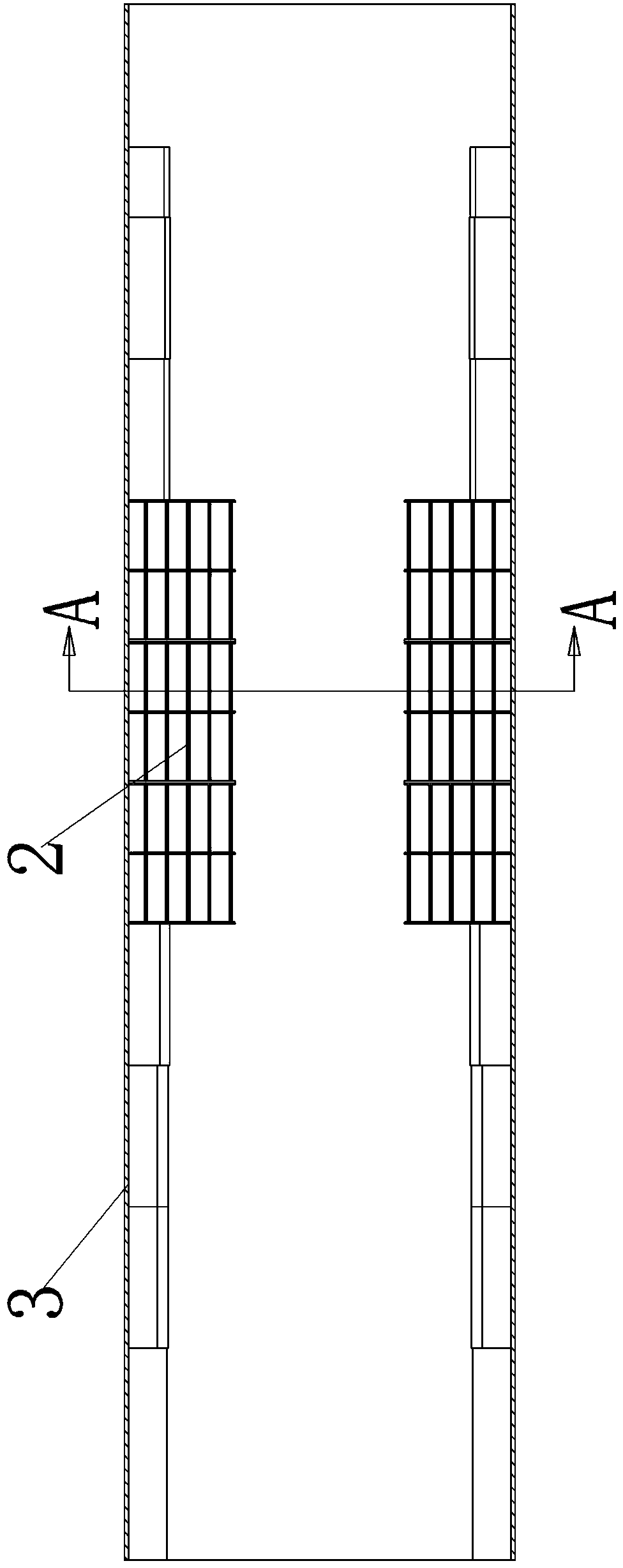

[0033] Example: see Figure 1-10 , a three-stage drum type sticky material dryer in the figure, including a bottom frame, an outer drum, a middle drum and an inner drum, end covers at both ends, and a breaking shaft in the center, the outer drum, the middle drum and the The inner rollers are set together concentrically in turn, the outer surface of the outer roller is supported on the rollers on the bottom frame, the lower parts of the end covers at both ends are connected to the bottom frame, and the end covers are sealed with the ends of the outer rollers. One of the end covers is Feeding end cover, the outer side of the end cover is provided with an air inlet and a feeding device, the feeding device is inserted into the inner drum after passing through the feeding end cover, and the other end cover is a discharge end cover, and the lower part of the end cover is set There is a bucket-shaped outlet, which is characterized by:

[0034] The dispersing shaft includes a cylindr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com