Preparation method of platinum nanoparticles

A technology of platinum nanoparticles and chloroplatinic acid, which is applied in the field of preparation of platinum nanoparticles, can solve the problems of sodium borohydride inhalation toxicity, high reaction risk factor, and environmental hazards, and achieve high application prospects and commercial value. Inexpensive, easy-to-remove effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] Add 0.8g of glucose and 0.2g of ascorbic acid into 30mL of deionized water, stir for 10min to completely dissolve the glucose and ascorbic acid, then place the above solution in a 60°C water bath, drop in 1mL of 10mM chloroplatinic acid, and react for 15min to obtain platinum nanoparticles Sol. Sampling from it, using a laser particle size analyzer (ZETASIZER 3000HS A ) to test the prepared platinum nanoparticles, the average particle size is 46nm.

Embodiment 2

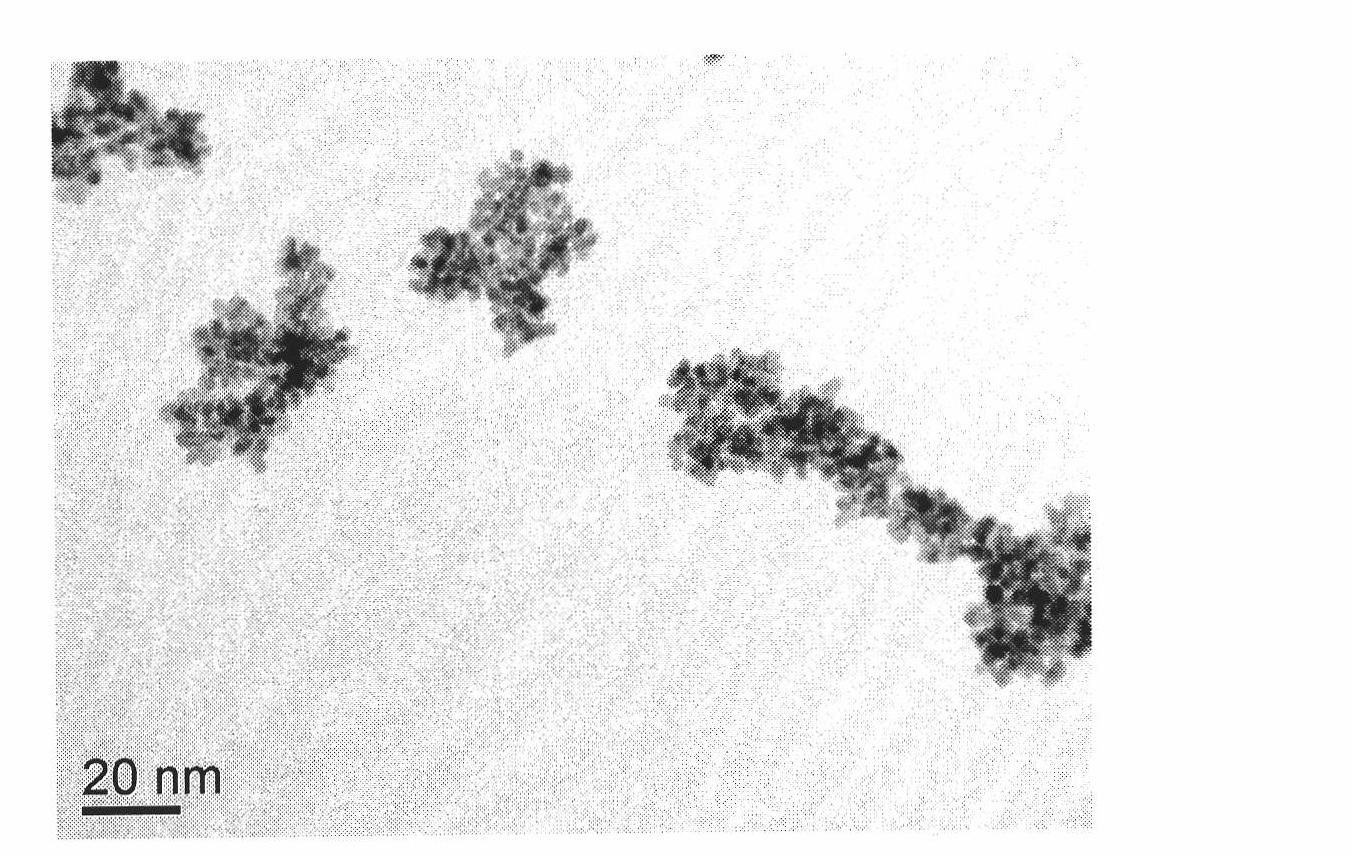

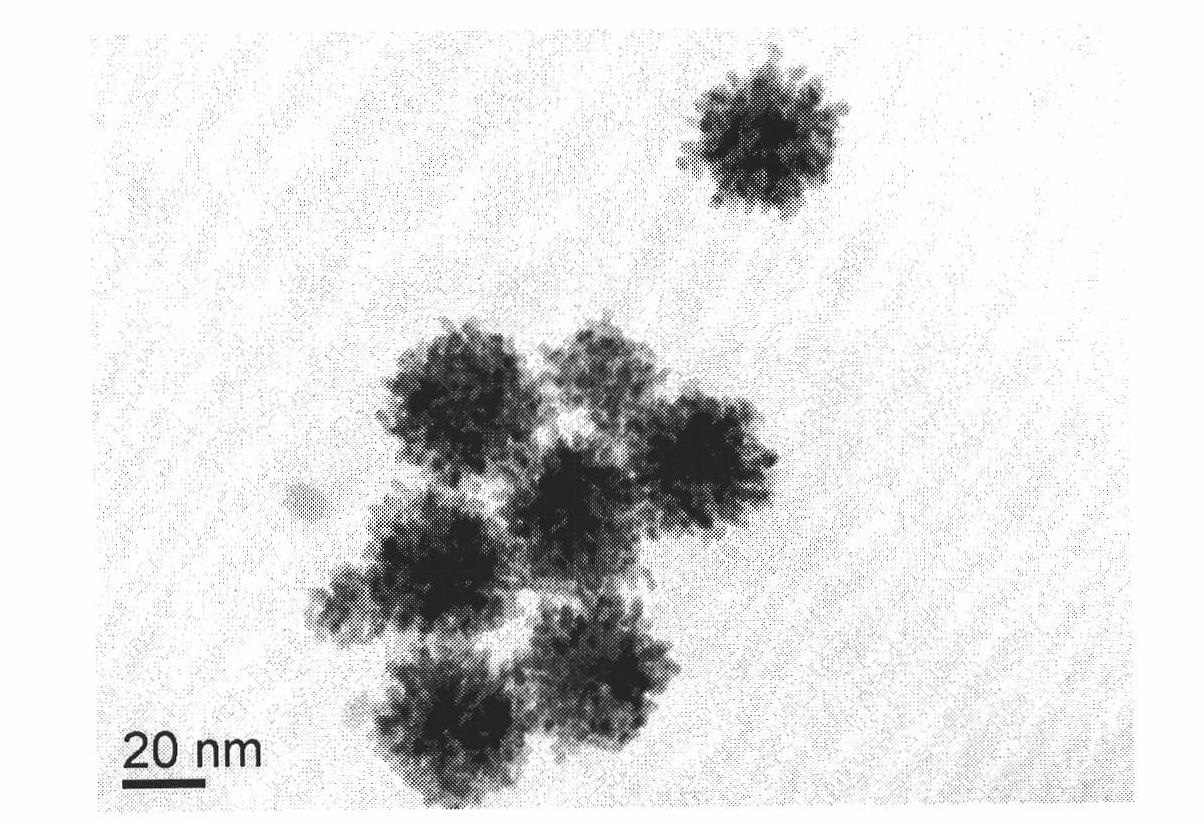

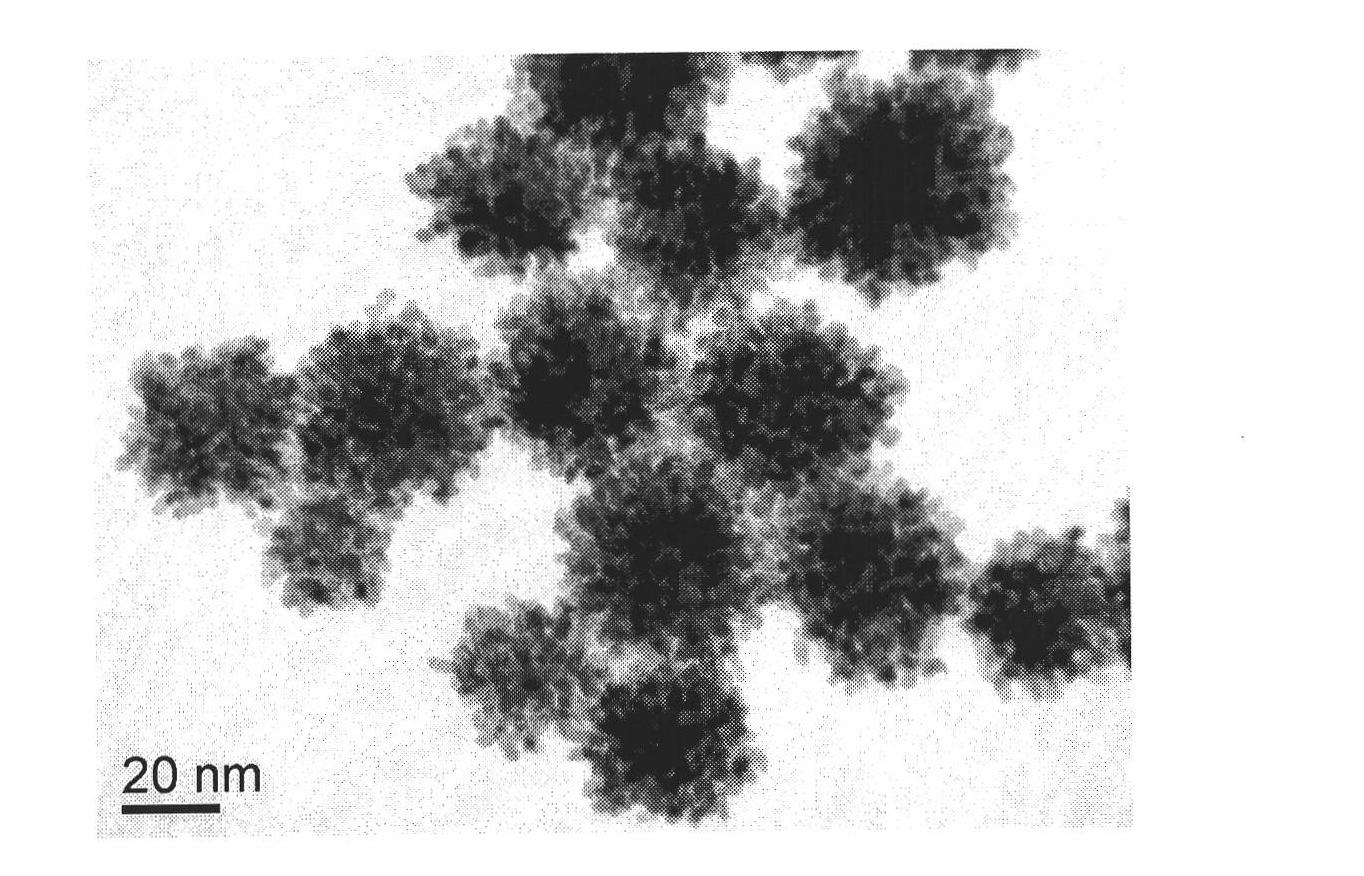

[0020] Add 0.54g of glucose and 0.132g of ascorbic acid into 30mL of deionized water, stir for 10min to completely dissolve the glucose and ascorbic acid, then place the above solution in a water bath at 80°C, drop in 1mL of 10mM chloroplatinic acid, and react for 5min to obtain platinum nanoparticles Sol. Take a sample from it, use the laser particle size analyzer to test the prepared platinum nanoparticles, the average particle diameter is 4.5nm, use the transmission electron microscope to carry out the morphology characterization of the sample, the obtained TEM picture is shown in figure 1 , it can be seen from the figure that the obtained platinum nanoparticles have good dispersion and an average particle diameter of 4nm, which is consistent with the results measured by the laser particle size analyzer.

Embodiment 3

[0022] Add 0.8g of glucose and 0.2g of ascorbic acid to 30mL of deionized water, stir for 10min to completely dissolve the glucose and ascorbic acid, then place the above solution in a water bath at 90°C, drop in 1mL of 20mM chloroplatinic acid, and react for 4min to obtain platinum nanoparticles Sol. Samples were taken therefrom, and the prepared platinum nanoparticles were tested using a laser particle size analyzer, and the average particle diameter was 35nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com