Ternary copper catalyst used in synthesis of dimethyl dichlorosilane and preparation method of ternary copper catalyst

A technology of dimethyldichlorosilane and catalyst, applied in the field of ternary copper catalyst and its preparation, to achieve the effects of easy control, prevention of volatilization, and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] Weigh 0.5g Cu(CH 3 COO) 2 , Dissolved in 40mL of 15% (volume ratio) glycerol aqueous solution, added the prepared 1M sodium hydroxide solution, adjusted the pH value to 6, placed in a polytetrafluoroethylene lined reactor at 120℃ and reacted for 15h. After the end, the product was filtered, washed with water and absolute ethanol 5 times each, and dried in a vacuum drying cabinet at 60°C for 8 hours. The obtained copper catalyst has the following composition after chemical analysis: 28% Cu (weight percentage, the same below), 49% Cu 2 O and 23% CuO.

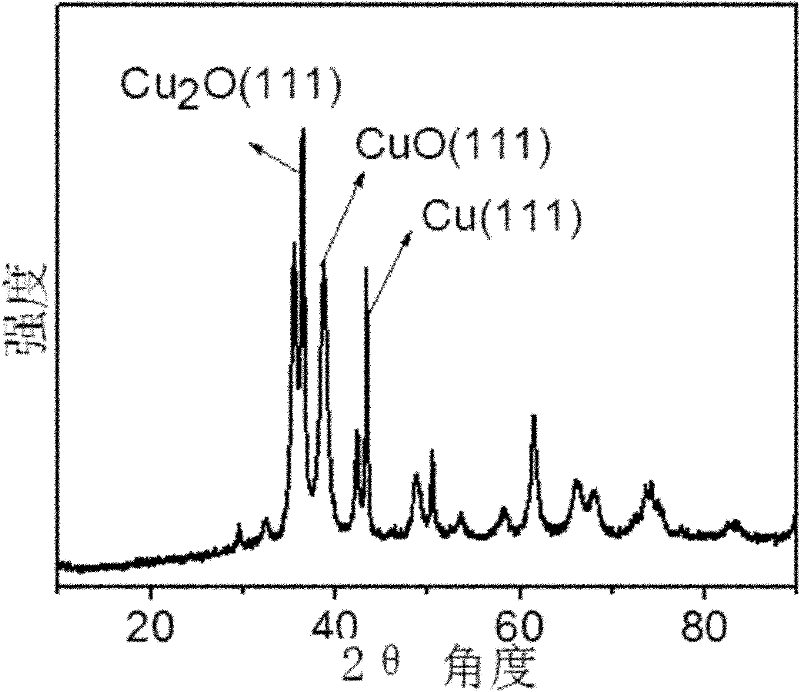

[0041] The ternary copper catalyst material prepared above was tested by X'PertPRO MPD multifunctional X-ray diffractometer produced by Panalytical Company (Panalytical) in the Netherlands.

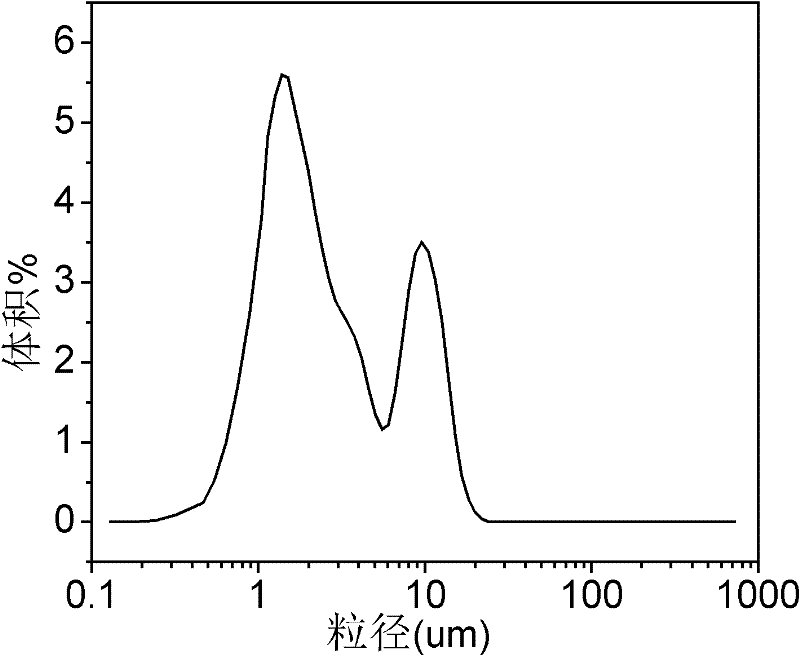

[0042] The ternary copper catalyst material prepared above was analyzed by the Dandong Baxter BT-9300Z laser particle size distribution analyzer.

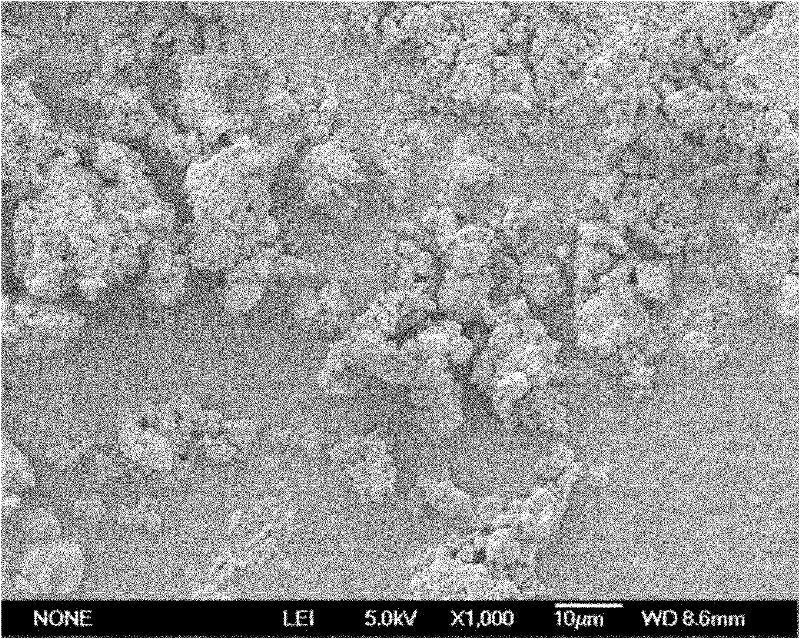

[0043] The surface morphology of the ternary copper catalyst material prepared above was obse...

Embodiment 2

[0050] Weigh 1g Cu(NO 3 ) 2 , Dissolved in 40mL of 40% (volume ratio) glycerol aqueous solution, add the prepared 3M sodium hydroxide solution, adjust the pH to 9, and place it in a polytetrafluoroethylene lined reactor at 180℃ to react for 24h. After the end, the product was filtered, washed with water and absolute ethanol 5 times each, and dried in a vacuum drying cabinet at 60°C for 8 hours. The obtained copper catalyst has the following composition after chemical analysis: 11% Cu, 68% Cu 2 O and 21% CuO.

[0051] Figure 5 Is the XRD pattern of the copper catalyst obtained in Example 2, where 2θ=36.4° is Cu 2 The characteristic peak of O, the shoulder peak composed of 2θ=35.5° and 2θ=38.7° is the characteristic peak of CuO, and 2θ=43.3° is the characteristic peak of Cu. It can be seen that the catalyst synthesized by this method is composed of CuO, Cu 2 A ternary copper catalyst composed of O and Cu.

[0052] Image 6 In order to analyze the particle size of the copper catalyst...

Embodiment 3

[0054] Weigh 2g CuSO 4 , Dissolved in 40mL of 75% (volume ratio) butanediol aqueous solution, added the prepared 5M sodium hydroxide solution, adjusted the pH value to 13, placed in a polytetrafluoroethylene lined reactor at 250℃ and reacted for 30h. After the end, the product was filtered, washed with water and absolute ethanol 5 times each, and dried in a vacuum drying cabinet at 60°C for 8 hours. The obtained copper catalyst has the following composition after chemical analysis: 43% Cu, 44% Cu 2 O and 13% CuO. Figure 5 Is the XRD diagram of the product, Image 6 For particle size analysis.

[0055] Figure 7 XRD pattern of the copper catalyst obtained in Example 3, where 2θ=36.4° is Cu 2 The characteristic peak of O, the shoulder peak composed of 2θ=35.5° and 2θ=38.7° is the characteristic peak of CuO, and 2θ=43.3° is the characteristic peak of Cu. It can be seen that the catalyst synthesized by this method is composed of CuO, Cu 2 A ternary copper catalyst composed of O and C...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com