Catalyst for C4 fraction selective hydrogenation and removal of alkyne, and preparation method thereof

A technology for removing acetylene catalyst and selective hydrogenation, which is applied in catalyst activation/preparation, hydrocarbons, chemical instruments and methods, etc., can solve the problems of unsatisfactory catalyst selectivity and activity, shorten the preparation period and reduce energy consumption , the effect of less acetylene

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0055] Preparation of vector

[0056] Use lanthanum-modified alumina as the carrier, wherein the content of lanthanum in the carrier is 2%, the alumina is calcined at 1000°C, and the specific surface area of the carrier is measured to be 155m 2 / g.

Embodiment 2

[0058] Preparation of Catalyst A

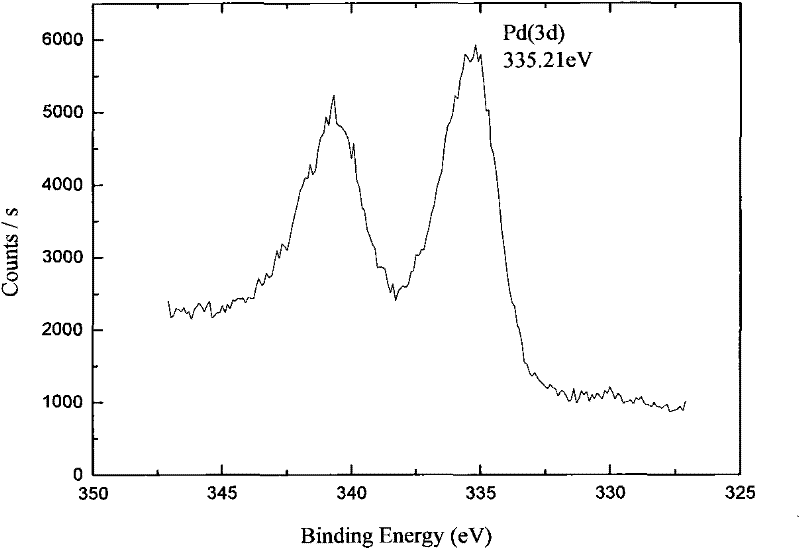

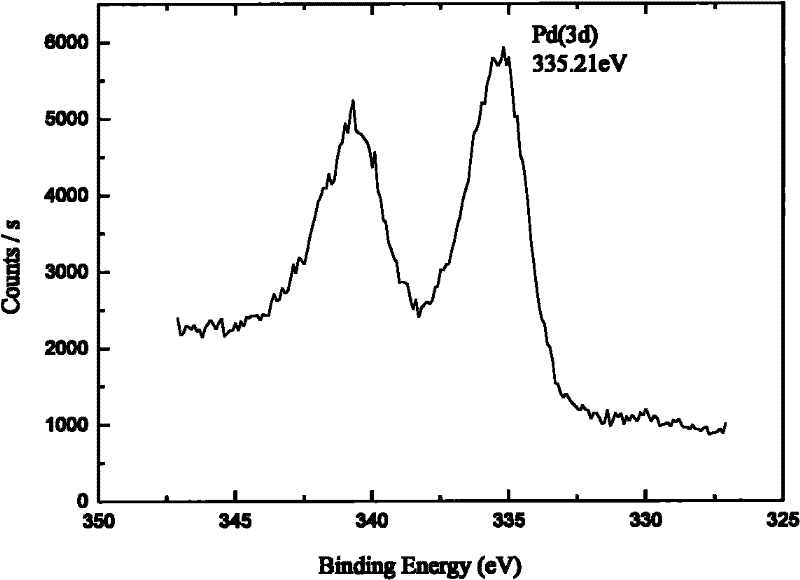

[0059] Configuration pH value is 1.4, concentration is the palladium nitrate solution 70ml of 2.86mgPd / ml (PH uses 1mol / l sodium hydroxide solution to regulate), takes by weighing the aluminum oxide carrier 100g in the embodiment 1, to the aluminum oxide carrier spraying configured Palladium nitrate solution, after standing for 20 minutes, take the mixed solution prepared by 20ml deionized water and 20ml isopropanol, pour it into the carrier that is loaded with Pd, pour out the excess solution after uniform dispersion. Use the product under vacuum 60 The Coγ radiation source was irradiated for 15 hours at a dose rate of 30Gy / min. The irradiated sample was dried at 120° C. for 6 hours to obtain catalyst A with a Pd content of 0.2%.

Embodiment 3

[0064] Preparation of Catalyst B

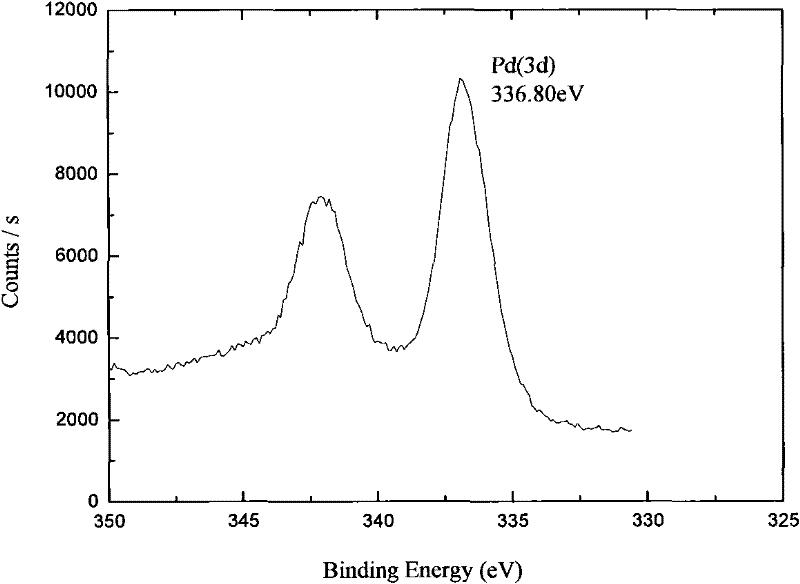

[0065] First spray the sodium carbonate solution on the 100g alumina carrier in Example 1, dry it and place it in an oven at 120°C for 12 hours; then configure 70ml of bismuth nitrate solution with a concentration of 20.29mg Bi / ml, spray it Put it on the above carrier, dry it in the oven at 120°C for 12 hours, then configure palladium nitrate (concentration 2.86mg Pd / ml), silver nitrate (concentration 1.57mg Ag / ml) and zinc nitrate (concentration 3.86mg Zn / ml) of the mixed solution 70ml, which is sprayed on the above-mentioned dried particle pellets, after standing for 20 minutes, the mixed solution prepared by 20ml water and 20ml isopropanol is poured into the pellets loaded with Pd, After uniform dispersion, the excess solution was decanted. Use the product under vacuum 60 The Coγ radiation source was irradiated for 15 hours at a dose rate of 30Gy / min. The irradiated sample was dried at 120°C for 12 hours to obtain Catalyst B with a Pd ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com