Fuel-cell catalyst with non-platinum core-shell structure and preparation method of fuel-cell catalyst

A fuel cell, shell structure technology, applied in chemical instruments and methods, physical/chemical process catalysts, battery electrodes, etc., can solve the problems of reducing the usage of precious metal Pt, cost, grain size and lack of microstructure, etc., to achieve the preparation method Simple and easy to implement, suitable for large-scale industrial production, and the effect of easy particle size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

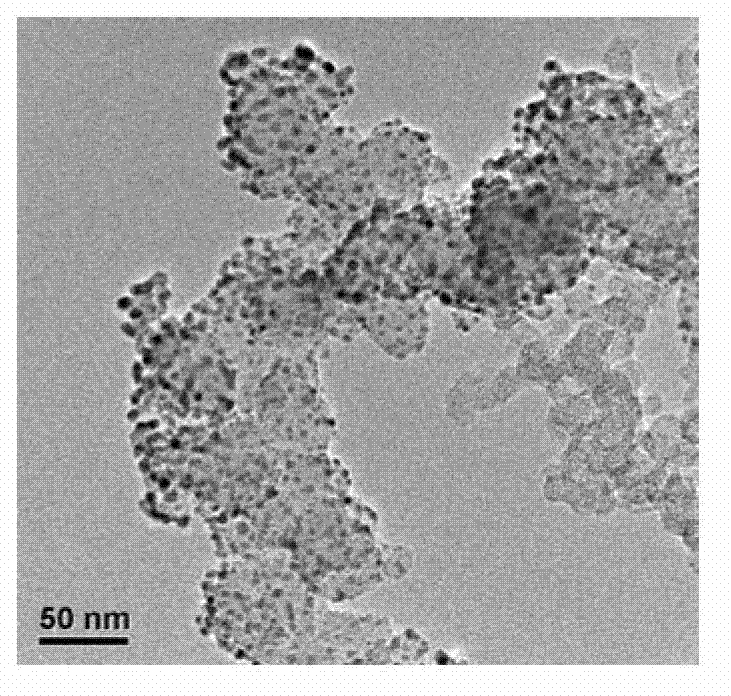

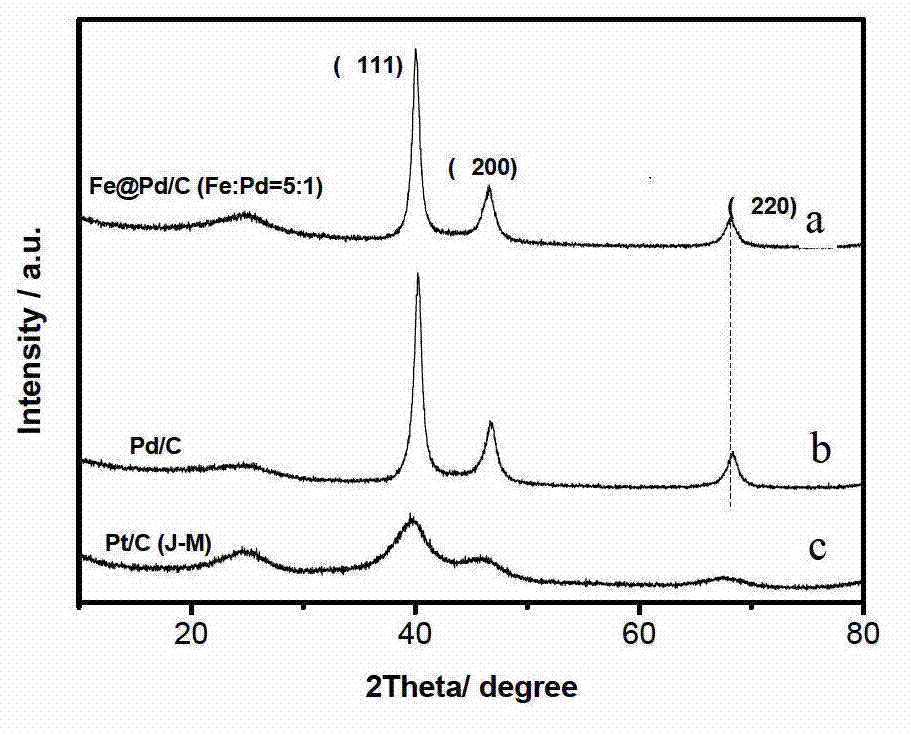

[0021] Example 1: First, 10 mg of activated carbon was dissolved in 6 mL of ethanol solution, ultrasonicated for 30 min, and then a protective gas of argon was introduced and stirred. After 30 min, 9.8 mg of reducing agent sodium borohydride was added, and then 1.67 mL (1 g / 100 mL) of palladium chloride solution was added dropwise, and the stirring was continued for 15 min. After the reaction, filter, wash with ultrapure water for 4 times, and dry under vacuum at 70° C. for 2 hours to obtain carbon-supported palladium nanocrystals Pd / C.

Embodiment 2

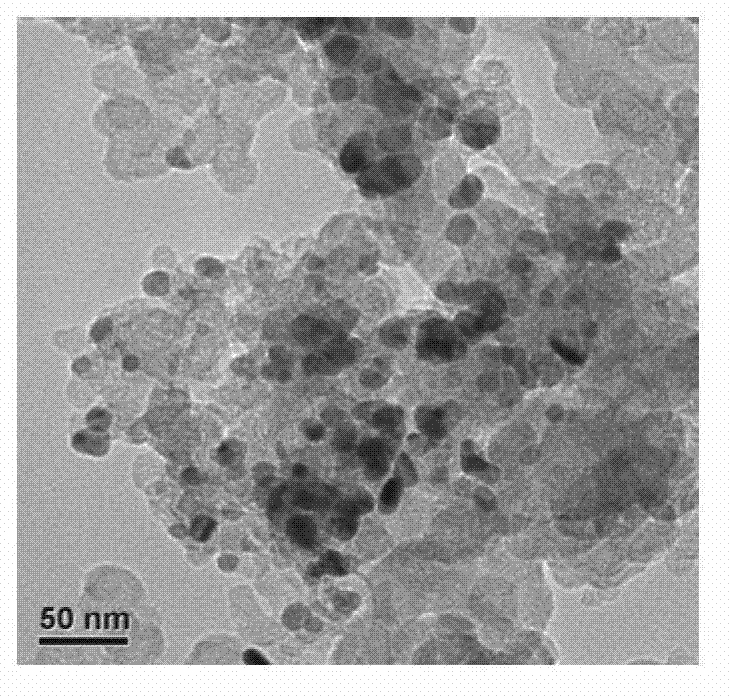

[0022] Example 2: First, 15 mg of activated carbon was dissolved in 8 mL of ultrapure water, ultrasonicated for 40 min, and then a protective gas of argon was introduced and stirred. After 50 minutes, add 10 mg of reducing agent sodium borohydride, and then add 2 mL of ferrous chloride aqueous solution (0.09 M) dropwise. After 15 minutes of reaction, add 0.64 mL of palladium chloride aqueous solution (1 g / 100 mL) dropwise for displacement reaction, and continue stirring for 20 minutes. After the reaction, filter, wash with ultrapure water 4 times, and dry under vacuum at 60°C for 3 hours to obtain a non-platinum core-shell catalyst FePd / C with nanocrystalline iron Fe as the core and thin-layer nanocrystalline palladium Pd as the shell. .

Embodiment 3

[0023] Example 3: First, 12 mg of activated carbon was dissolved in 7 mL of ultrapure water, ultrasonicated for 45 min, and then a protective gas of nitrogen was introduced and stirred. After 50 minutes, 11 mg of reducing agent sodium borohydride was added, and then 2 mL of ferrous sulfate aqueous solution (0.09 M) was added dropwise. After reacting for 15 minutes, 0.6 mL of palladium chloride aqueous solution (1 g / 100 mL) was added dropwise for displacement reaction, and stirring was continued for 20 minutes. After the reaction, filter, wash 5 times with ultrapure water, and dry under vacuum at 50°C for 3 hours to obtain a non-platinum core-shell catalyst FePd / C with nanocrystalline iron Fe as the core and thin-layer nanocrystalline palladium Pd as the shell. .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com