Method of improving coercivity of sintering Nd-Fe-B magnetic material

A neodymium-iron-boron and magnetic material technology is applied in the field of sintered neodymium-iron-boron magnetic materials, which can solve the problems of reducing, consuming rare earth, and decreasing, and achieves the effect of ensuring high magnetic energy product, reducing average particle size and narrow particle size distribution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

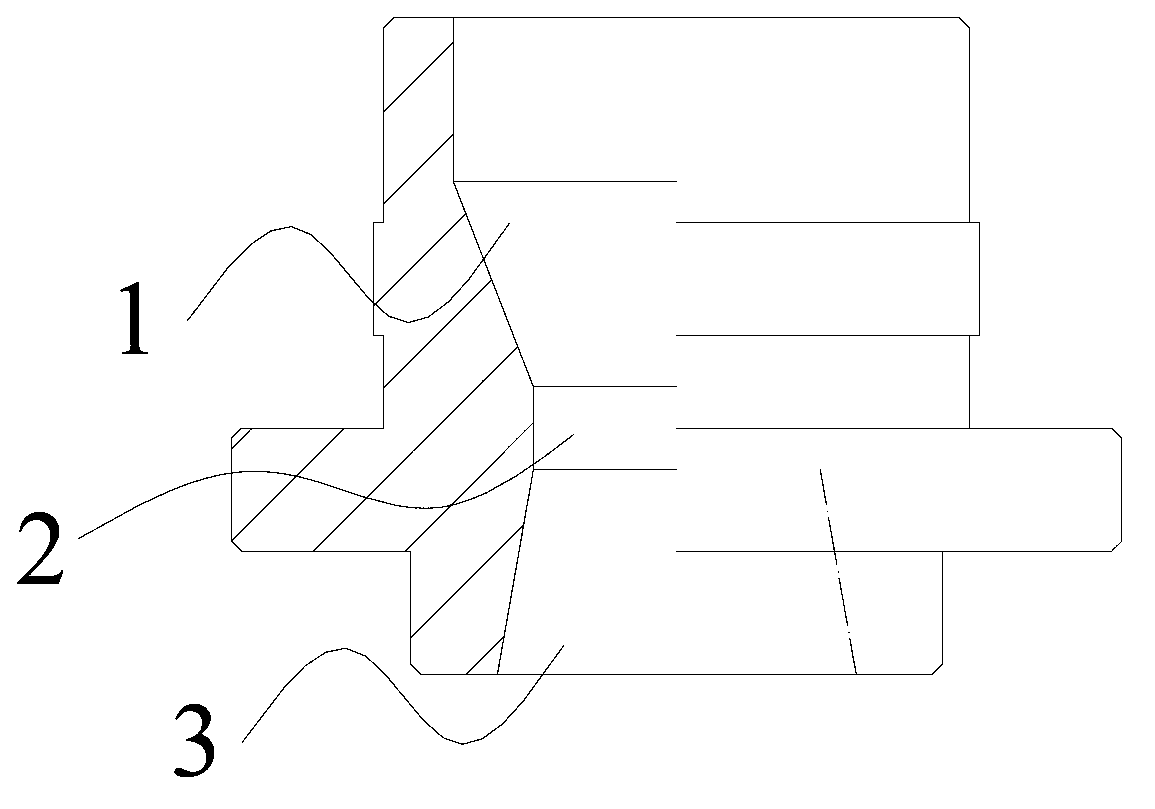

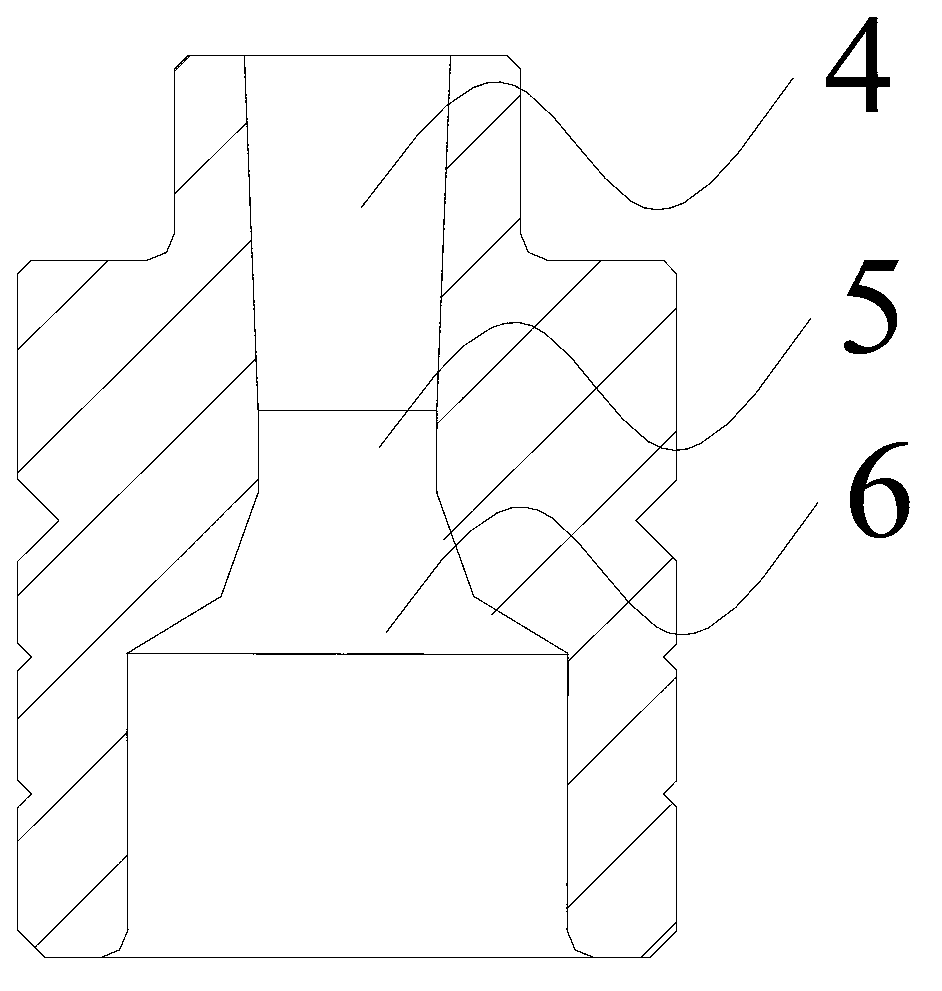

[0036] The retractable jet mill system of the present invention includes a bottom nozzle with an internal airflow channel and a side nozzle with an internal airflow channel. Such as figure 1 As shown, the bottom nozzle is composed of the first converging section 1, the first throat section 2 and the first diverging section 3 connected in sequence; the specific connection method is: the end of the first converging section 1 with a smaller opening and the first The sections 2 are connected, and the end of the first diffuser section 3 with a smaller opening is connected to the first throat section 2 . Such as figure 2 As shown, the side nozzle is composed of the second converging section 6, the second throat section 5 and the second diffusing section 4 which are connected in sequence; The segment 5 is connected, and the smaller opening end of the second diffuser segment 4 is connected to the second throat segment 5 .

[0037] The bottom nozzle and side nozzle structure of the...

Embodiment 2

[0039] Homogenized magnetic powder + high temperature liquid phase low temperature sintering

[0040] (1) The design composition is Nd 31 co 1 Cu 0.2 Fe 66.82 B 0.98 The quick-setting sheet is placed in a sintering furnace that can be vacuumed, vacuumed, and hydrogen gas is introduced to keep the hydrogen pressure in the sintering furnace at 5×10 5 Pa, keep it for 2 hours, keep the pressure and cool to room temperature, then vacuumize and dehydrogenate. After the vacuum degree reaches below 1kPa, start to heat up to 500°C and keep it for 3 hours for dehydrogenation.

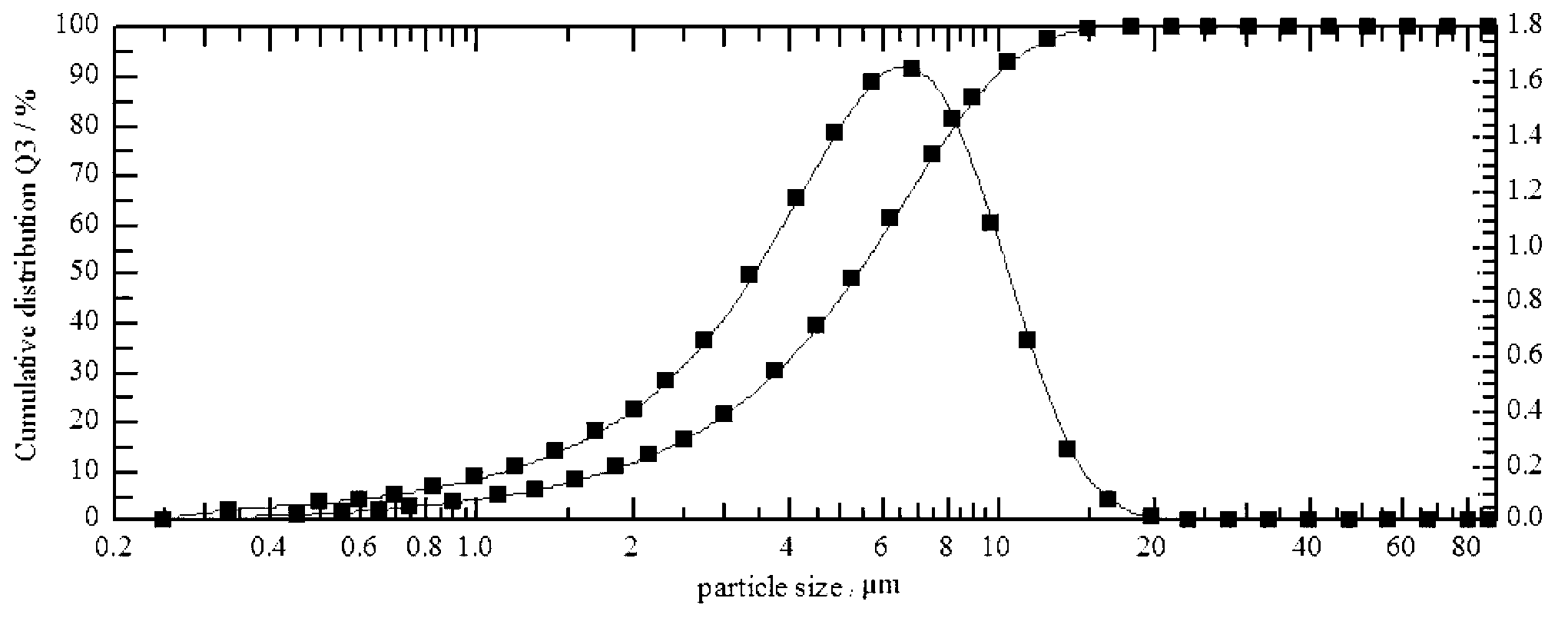

[0041] (2) Under the protection of nitrogen, place the hydrogen powder in the jet mill of Example 1 and grind it until the average particle size of the main phase alloy powder is 3.39 μm, and the powder dispersion (D90-D10) / (2D50) is less than 0.8, Obtain magnetic powder; put the obtained magnetic powder into a powder mixing machine for powder mixing, after mixing evenly, the homogenized powder is oriented a...

Embodiment 3

[0047] Traditional grinding powder magnetic powder + high temperature liquid phase low temperature sintering

[0048] In addition to step (2) under the protection of nitrogen, the hydrogen powder is placed in the existing airflow mill with a linear airflow acceleration mechanism for grinding, and the average particle size is 3.29μm, and the powder dispersion is (D90-D10) / (2D50)= Except for the magnetic powder of 0.827, the other operations were the same as in Example 2 to obtain NdFeB magnetic materials.

[0049] The obtained NdFeB magnetic material is processed into a sample of Φ10mm×10mm, and the magnet performance is shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com