Nanogold shell coated upconversion nanocrystal composite structure material and preparation method thereof

A nanocrystalline composite and structural material technology, applied in nanotechnology, nano-optics, luminescent materials, etc., can solve the problems of incomplete core-shell structure, large nano-particle size, weak biological tissue penetration ability, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

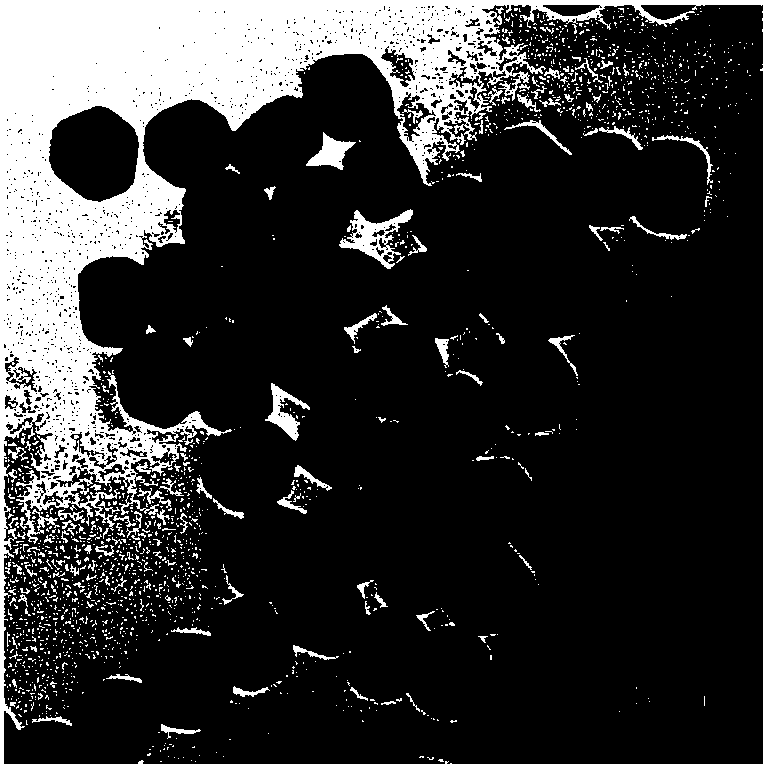

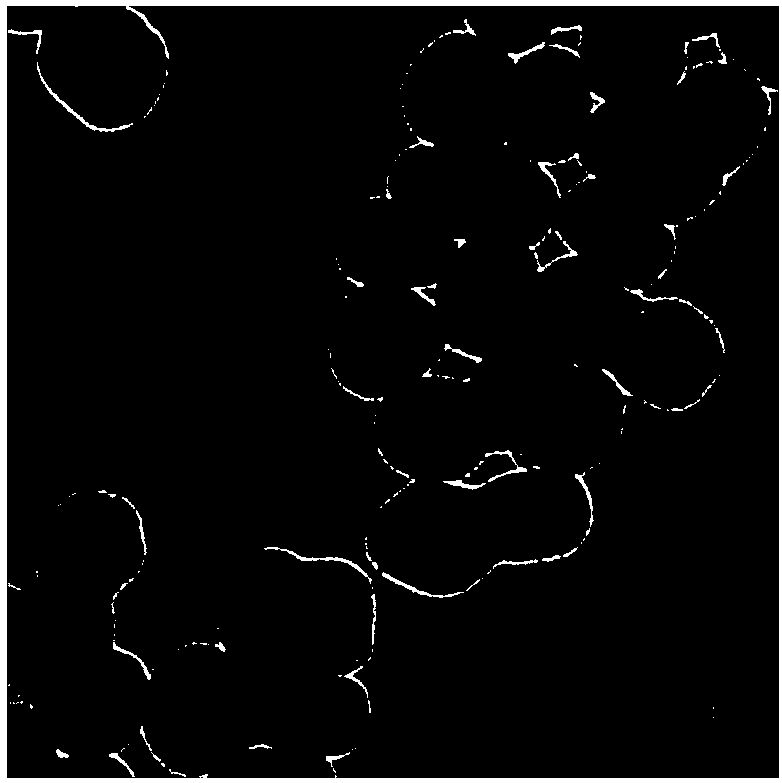

[0102] The preparation method of the above nano-gold shell-coated up-conversion nanocrystalline composite structure up-conversion luminescent material specifically includes the following steps:

[0103] (1) According to NaMF 4 :xYb,yN@SiO 2 Experimental design of @Au(NSA) composite structure, firstly synthesize pure NaMF 4 :xYb, yN(NYF) matrix, measure Y(NO 3 ) 3 , Yb(NO 3 ) 3 , and measure Tm(NO 3 ) 3 , Er(NO 3 ) 3 、Ho(NO 3 ) 3 One or more of them are placed in a beaker, weigh 0.168g NaF and 10mL H 2 O (centrifuge tube sonicated); weigh 0.3g NaOH, 1.5mL H 2 O, 10mL ethanol and 5mL OA in the above beaker; drop the prepared NaF solution into the beaker, and stir rapidly for 30min; add the solution into the reaction kettle and heat to 200°C for 8-24h; wait for the above solution to cool to room temperature, 10000rpm Centrifuge and wash three times, dry at 60°C for 24 hours, then disperse in appropriate amount of cyclohexane for use;

[0104] Or use another syntheti...

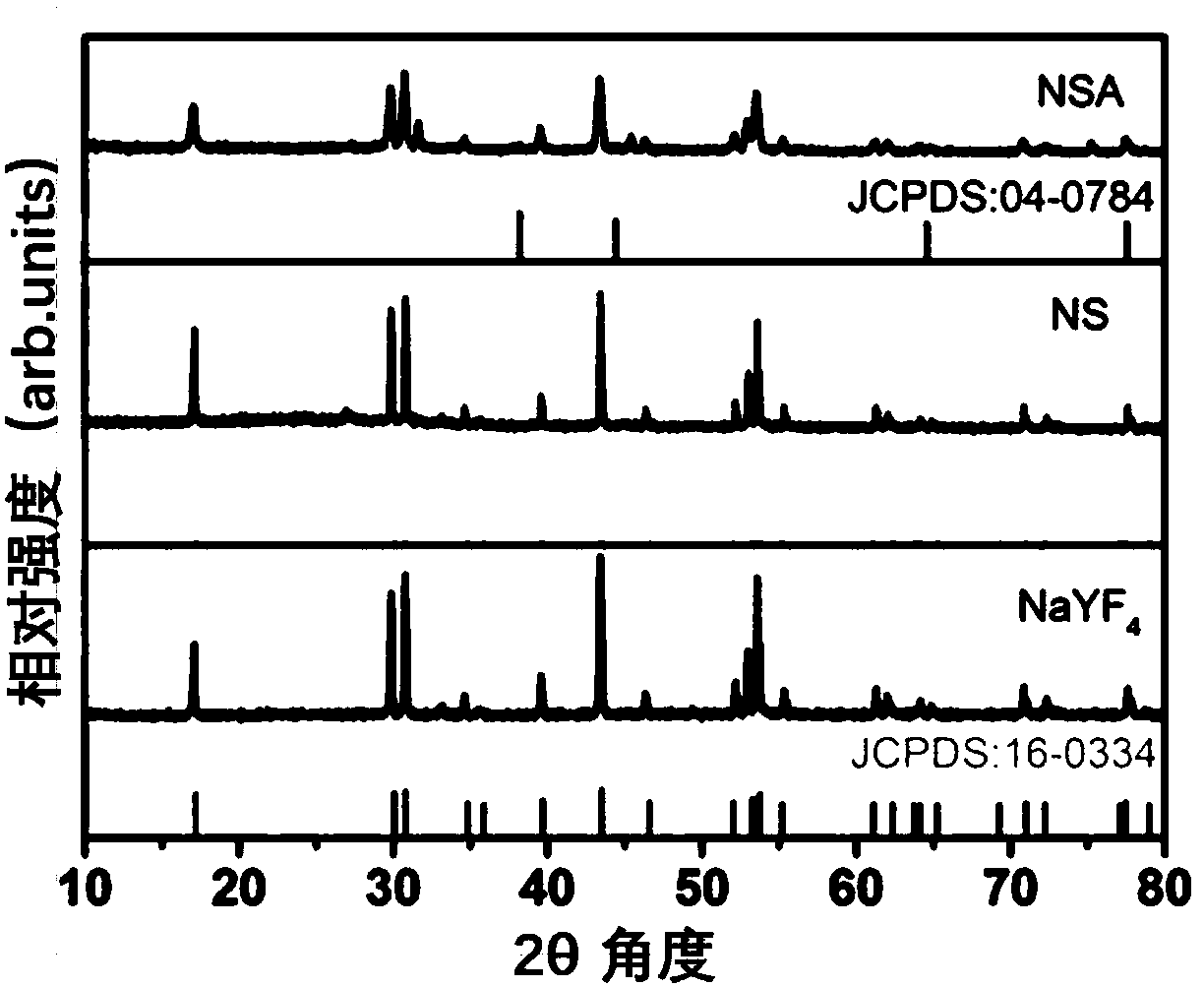

Embodiment 1

[0136] Ⅰ. NYF1 (NaYF 4 : 18%Yb, 2%Er) preparation: (1) weigh 0.2428g YCl 3 , 0.0698gYbCl 3 and 0.0076g ErCl 3 Put the powder in a three-necked flask, (2) dropwise add OA:ODE=14:16mL to the three-necked flask, heat at 160°C for 30min, and cool to room temperature; (3) Take a new beaker and weigh 0.148g NH 4 F and 0.1g NaOH in 10mL methanol solution, ultrasonically disperse for 30min; (4) Add the solution in step (3) dropwise into the three-necked flask, heat to 70°C for 30min; continue to heat to 100°C for 10min; (5) The temperature was raised to 280°C and heated for 1h (N 2 protection, condensed and refluxed); (6) centrifuged and washed with ethanol for 3 times, dried at 60°C for 20 hours, and dispersed in 50 mL of cyclohexane.

[0137] Ⅱ.NS1 (NaYF 4 :18%Yb,2%Er@SiO 2 ) preparation: (1) Take 9 mL of dispersed NYF sample into a beaker, add dropwise 8 mL of cyclohexane and 1 mL of CO-520 for ultrasonic dispersion for 1 min; (2) continue to drop 100 μL of ammonia water, and...

Embodiment 2

[0144]Ⅰ. NYF1 (NaYF 4 : 18%Yb, 2%Er) preparation: (1) weigh 0.2428g YCl 3 , 0.0698gYbCl 3 and 0.0076g ErCl 3 Put the powder in a three-necked flask; (2) Add OA:ODE=14:16mL dropwise to the three-necked flask, heat at 160°C for 30min, and cool to room temperature; (3) Take a new beaker and weigh 0.148g NH 4 F and 0.1g NaOH in 10mL methanol solution, ultrasonically disperse for 30min; (4) Add the solution in step (3) dropwise into the three-necked flask, heat to 70°C for 30min; continue to heat to 100°C for 10min; (5) The temperature was raised to 300°C and heated for 1h (N 2 protection, condensed and refluxed); (6) centrifuged and washed with ethanol for 3 times, dried at 60°C for 20 hours, and dispersed in 50 mL of cyclohexane.

[0145] Ⅱ.NS1 (NaYF 4 :18%Yb,2%Er@SiO 2 ) preparation: (1) Take 9 mL of dispersed NYF sample into a beaker, add dropwise 8 mL of cyclohexane and 1 mL of CO-520 for ultrasonic dispersion for 1 min; (2) continue to drop 100 μL of ammonia water, and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com