Method for mechanical characterization of a metal material

A technology of metal materials and mechanical properties, applied in the field of aviation turbines, which can solve problems such as difficult implementation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

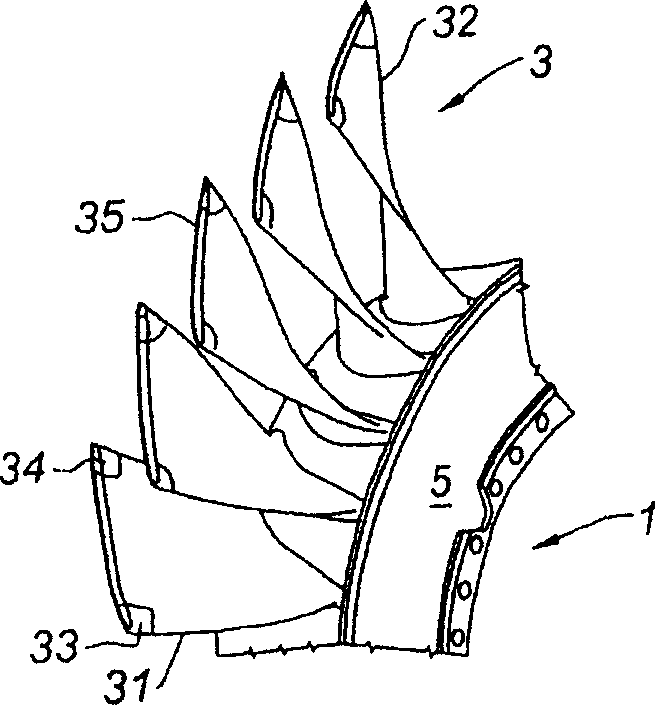

[0033] figure 1 It is a part of the single-blade wheel 1. The blades 3 are radial and distributed around the periphery of the disc 5 . The device is monolithic, that is to say it is either machined from a single blank or manufactured by welding at least some of its elements. In particular, the blades are not attached to the wheel by detachable mechanical means. Areas susceptible to damage are the leading edge 31 , the trailing edge 32 , the leading edge corner 33 , the trailing edge corner 34 and the end line 35 of the wing tip assembled in thin sections forming what is known as a weatherstrip.

[0034] The observed damage depends on the location of the area. For example at the leading edge, trailing edge or wing corner, the damage may be material loss or cracks due to the impact of foreign bodies. At the wing tips, they are often worn due to friction with the engine casing.

[0035] Depending on the area of damage, some material is removed in such a way that the geomet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com