A pavement structural mechanical behavior testing device and method

A technology of pavement structure and test device, which is applied in soil material testing, material inspection products, etc., can solve the problems of high consumption of manpower and material resources, limited test results, poor controllability, etc., and achieve the effect of ensuring accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

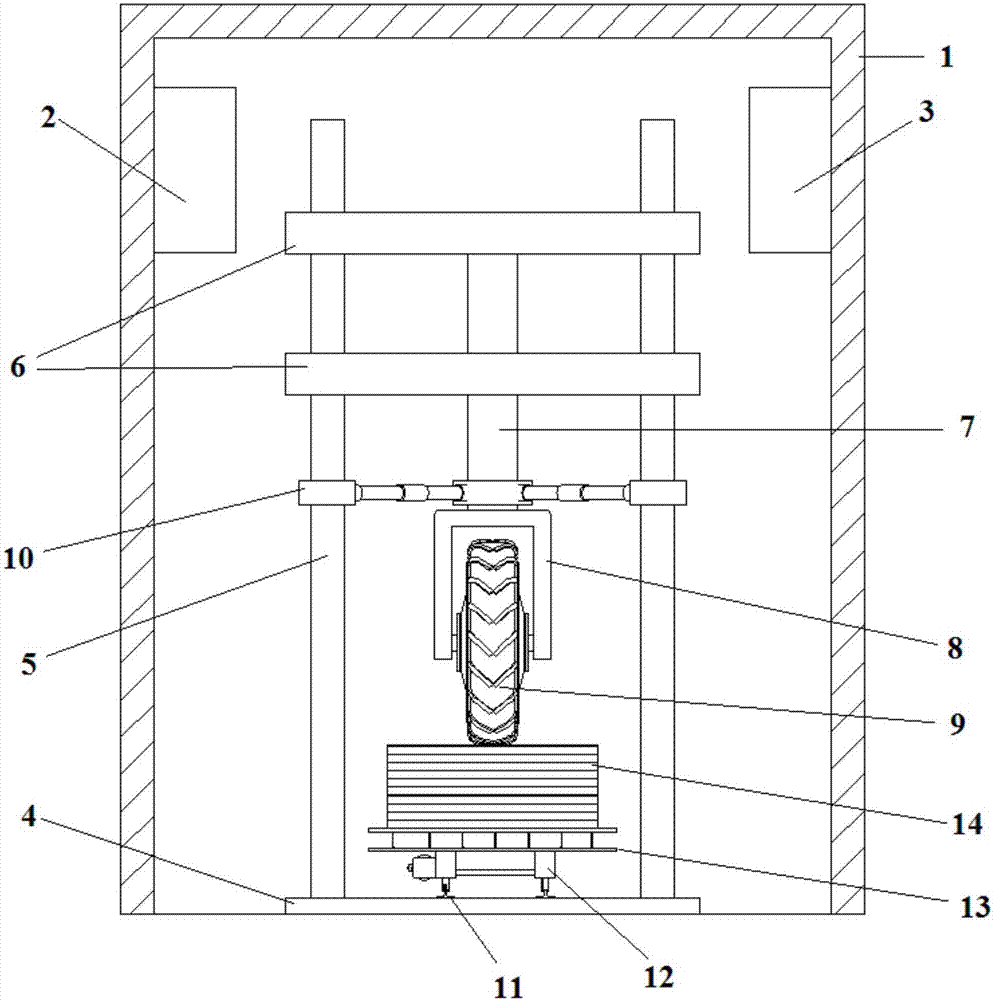

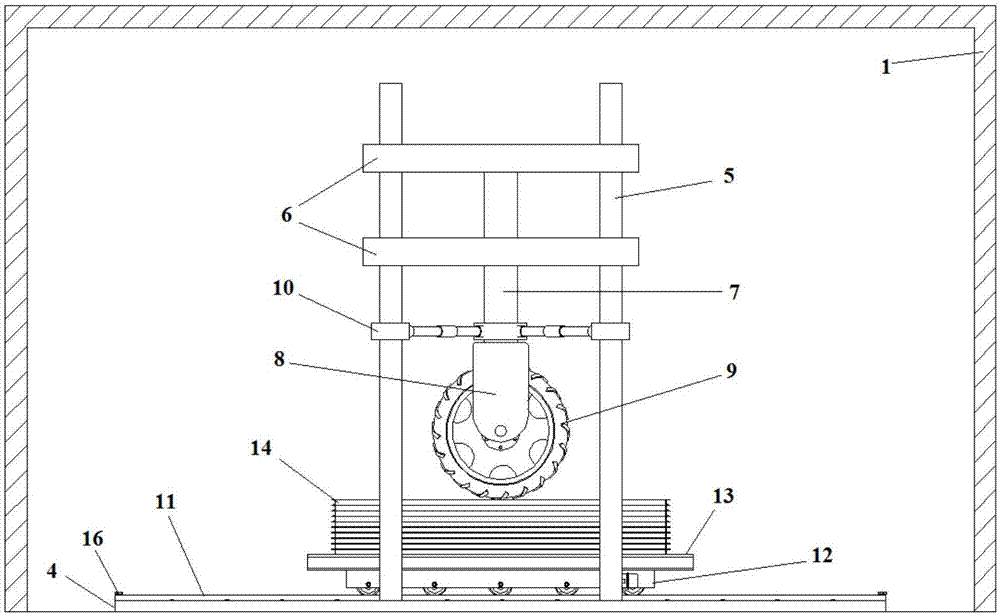

[0063] Such as Figure 1 to Figure 11 As shown, the present embodiment provides a test device for the mechanical behavior of pavement structures, including a thermal insulation room 1, a temperature control system 2 and a humidity control system 3 are installed in the thermal insulation room 1, and a base 4 is provided at the bottom of the thermal insulation room 1. 4 is provided with a group of columns 5 around, and the lifting platform 6 that can lift on the column 5 is installed on the column 5, and the telescopic oil cylinder 7 stretching out the bottom of the lifting platform 6 is installed on the lifting platform 6, and the telescopic oil cylinder 7 is vertically arranged with the base 4, The bottom end of telescopic oil cylinder 7 is provided with loading mechanism 8, and tire 9 is installed on loading mechanism 8;

[0064] The tire positioning mechanism 10 is installed on the column 5 and the telescopic oil cylinder 7, and the tire positioning mechanism 10 includes a c...

Embodiment 2

[0082] This embodiment provides a method for testing the mechanical behavior of pavement structures. The method uses the test device for the mechanical behavior of pavement structures described in Example 1, and specifically includes the following steps:

[0083] Step 1, preliminary preparation:

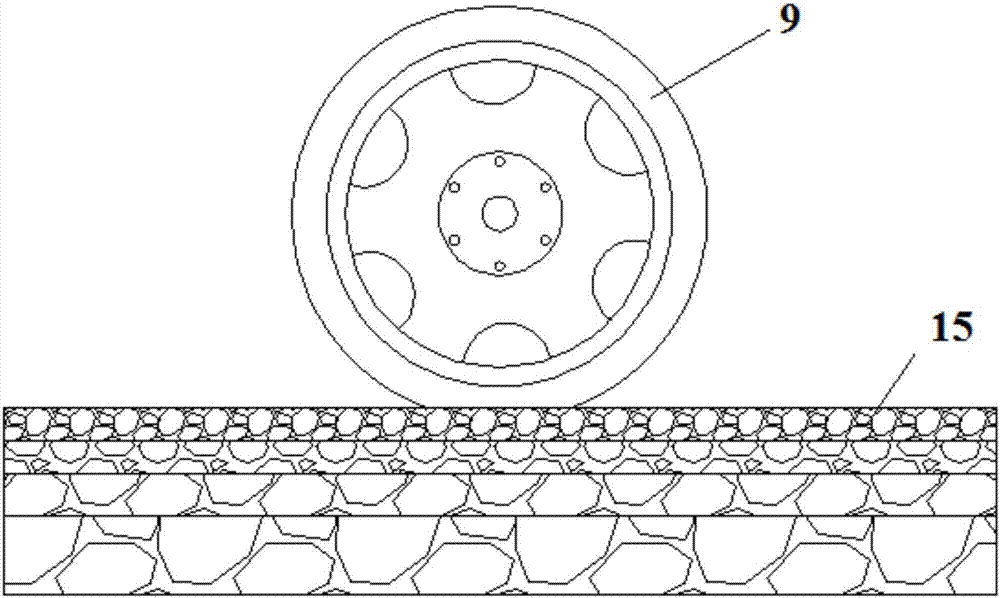

[0084] For the pavement structure to be studied, the preliminary calculation of pavement mechanics is used to determine the key damage area of the pavement structure and the restraint stiffness of this area. The stiffness of the sample box 14 and the support platform 13 is fine-tuned to ensure that the constraint stiffness of the critical damage area is consistent with the actual road surface;

[0085] Step 2, sample making:

[0086] On the basis of step one, the determined sample box 14 and support platform 13 are installed on the wheel box 12 , and the wheel box 12 is installed on the guide rail 11 . Vibration and compaction method is adopted to make pavement material and the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com