Determination method of overlying rock isolation grouting filling layer based on borehole injection flow measurement

A technology for isolating grouting and injection flow, which is applied in the directions of measurement, filling, earthwork drilling, etc., and can solve problems such as difficult implementation, high cost, and inability to detect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

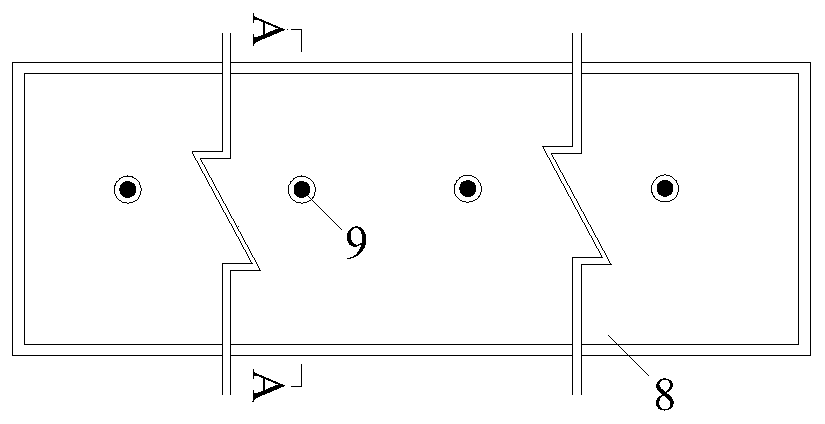

[0042] 1) Randomly select a grouting borehole 9 as the grouting filling layer in the mining face to determine the grouting borehole;

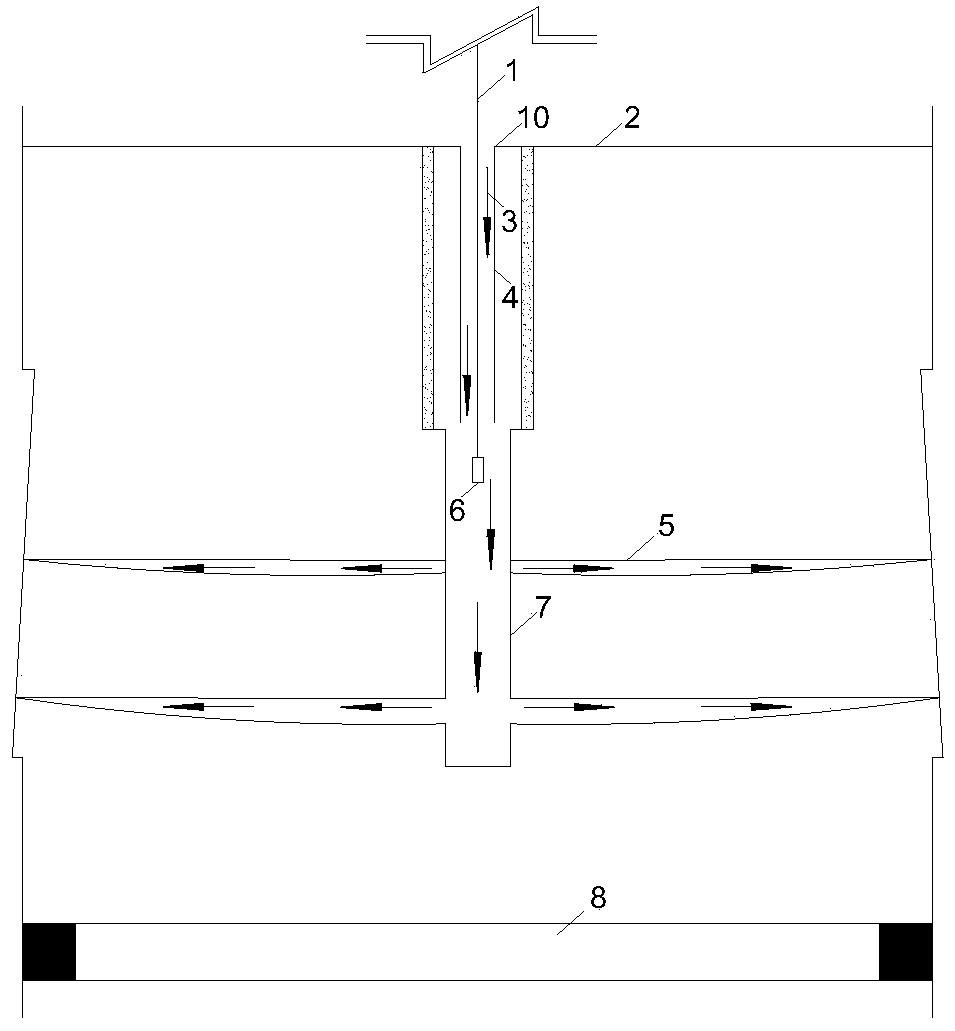

[0043] 2) During the mining process of the coal mining face 8 and before the grouting of the grouting borehole 9, a blowout preventer is connected to the wellhead of the grouting borehole 9; water is injected into the grouting borehole 9 at a steady flow rate; The cable 1 lowers the downhole flowmeter 6 into the grouting drill pipe 4 at a constant speed from the top 10 of the grouting drill pipe through the blowout preventer;

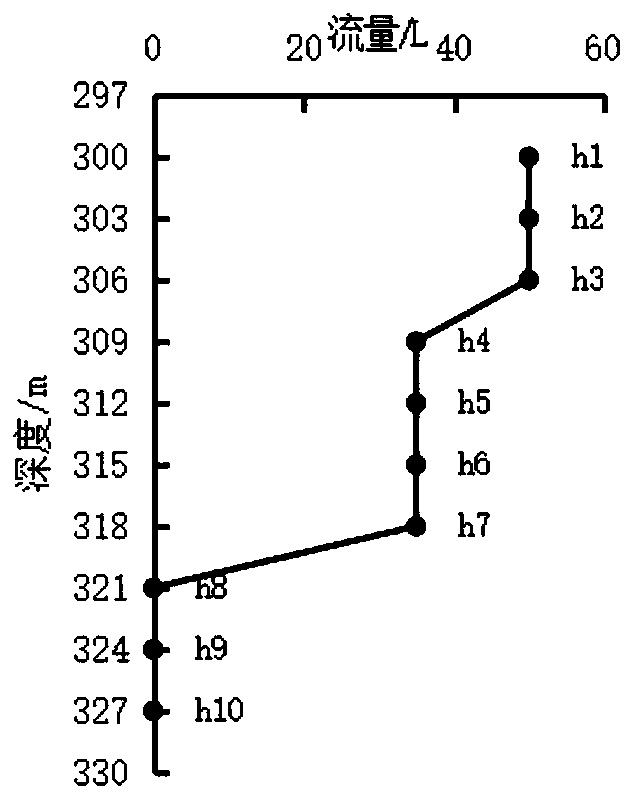

[0044] 3) When the downhole flowmeter 6 is lowered to the top of the open hole section 7, the first fixed-point measurement is started; the measurement adopts the hovering and continuous acquisition method, that is, the downhole flowmeter 6 is maintained at a certain depth, and the downhole flowmeter 6 automatically stores The time, depth and corresponding flow value are using a direct-reading flowmeter; the above inform...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com