Method for decalcifying hydrocarbon oil raw material using quaternary ammonium salt

A technology of quaternary ammonium salt and hydrocarbon oil, which is applied in the direction of refined hydrocarbon oil and petroleum industry, etc. It can solve the problems of large power consumption in electric desalination process and low decalcification rate of hydrocarbon oil, so as to save power consumption and shorten the time of electric desalination , Improve the effect of decalcification efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~6

[0023] This group of embodiment adopts actual crude oil sample, example Liaohe high acid value heavy crude oil, specific gravity 0.92 g / cm 3 , colloid 13%, Ca content 46.3ppm; Dagang crude oil (calcium content 104ppm); Shengli Oilfield (calcium content 33.67ppm); Luning pipeline oil (calcium content 26.42ppm), Iranian dirty oil (calcium content 69.7ppm), Iranian residual oil (calcium content 241.1ppm).

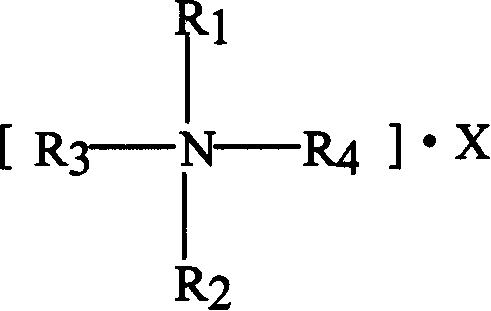

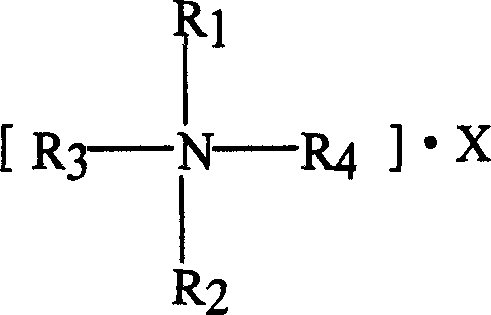

[0024] Mix deionized water, 50ppm BP2040 demulsifier (produced by Henan Luoyang Mengjin Petrochemical Anticorrosion Material Factory), different concentrations of precipitants and different concentrations of quaternary ammonium salts, with 70 grams of crude oil with different calcium contents, at 60 ° C, 1000 V / Under the centimeter electric field, act for 6 minutes, then separate the crude oil and water, and measure the calcium content in the crude oil after removal, and the results are listed in Table 1. Wherein in embodiment 1, quaternary ammonium salt is C 16 h 33 NH 3 ...

Embodiment 7

[0033] By each step and condition of embodiment 1, just do not add demulsifier, its result decalcification rate is 83.9%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com